Heavy hydraulic overturn-rotation sucker suspender

A technology of hydraulic overturning and rotating suction cups is applied in the field of spreaders, which can solve the problems of inability to adapt to materials, curing of the spreader structure, inconvenient and flexible use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Now the present invention is further described in conjunction with description of drawings and embodiments:

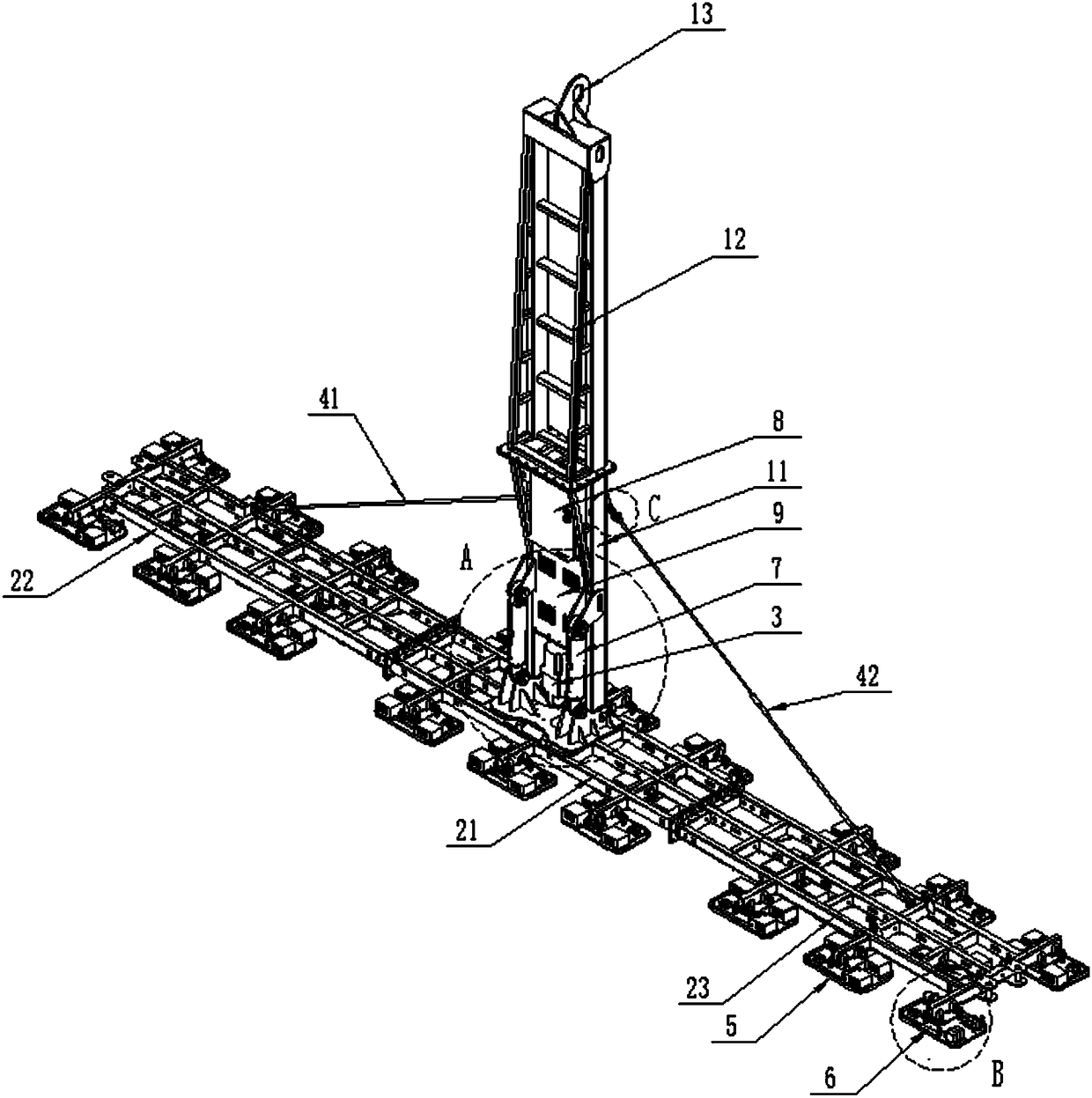

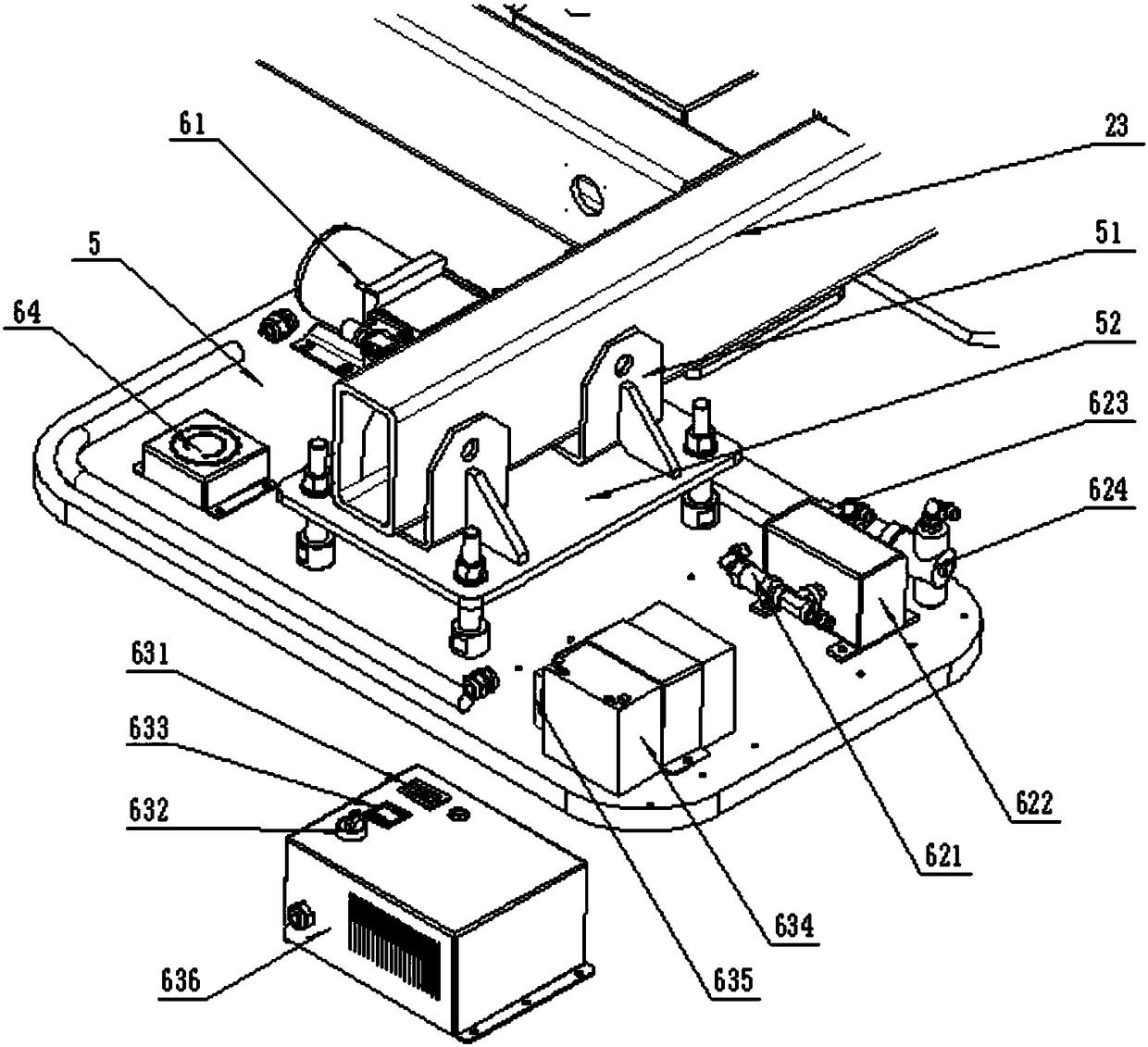

[0028] according to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a heavy-duty hydraulic flip rotating suction cup spreader includes a boom, a suction cup frame, a rotating mechanism 3, a suction cup 5, a vacuum system 6 and a turning mechanism 7.

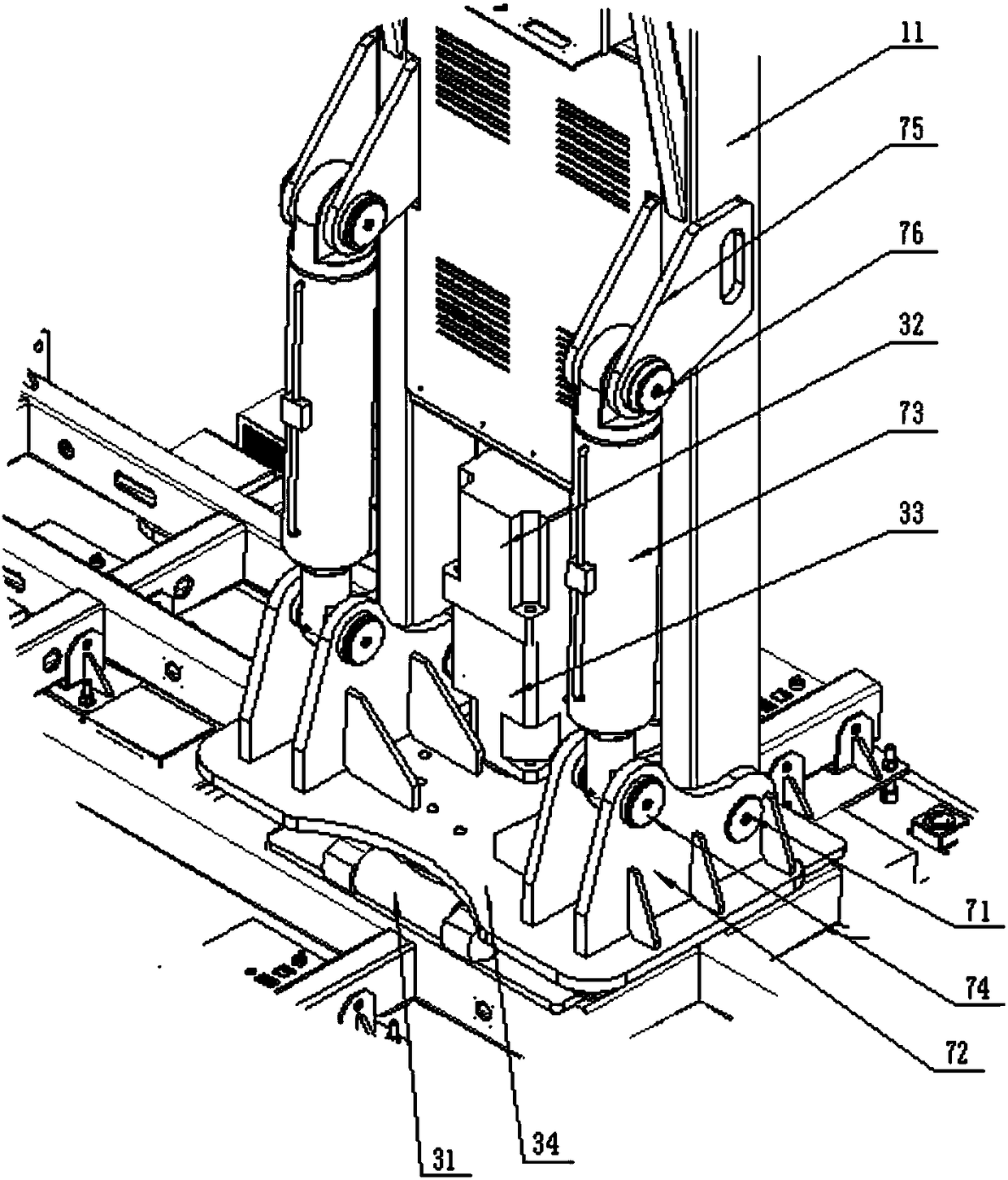

[0029] The turning mechanism 7 includes a turning shaft 71 , a turning plate 72 , a hydraulic cylinder 73 , a hydraulic pump, a hydraulic valve group, a battery B and a mounting flange 34 . The hydraulic pump, hydraulic valve group and hydraulic oil cylinder are connected in sequence through pipelines, and the storage battery B is connected to the hydraulic pump and hydraulic valve group respectively. The hydraulic valve group is at least one of a pressure control valve, a flow control valve and a direction control valve.

[0030] The turning plate 72 is fixed on the top of the mounting fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com