A plate condenser with liquid separation function

A condenser and liquid separation technology, applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problems of reducing heat transfer temperature difference, low condensation heat transfer coefficient, etc., to reduce heat transfer temperature difference and operation failure The effect of low rate and reduced liquid film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

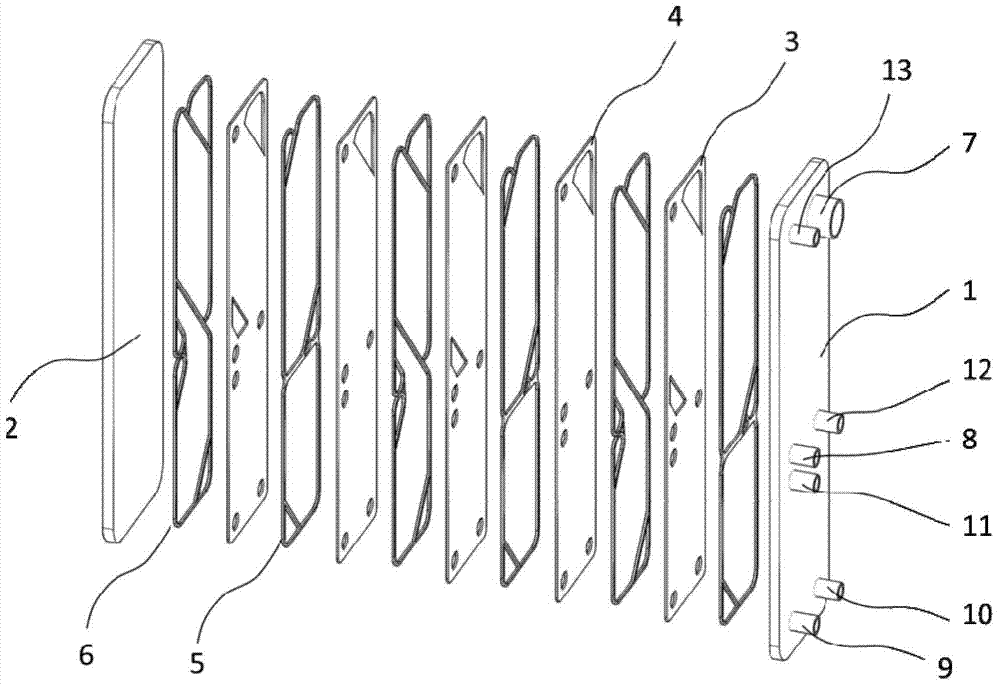

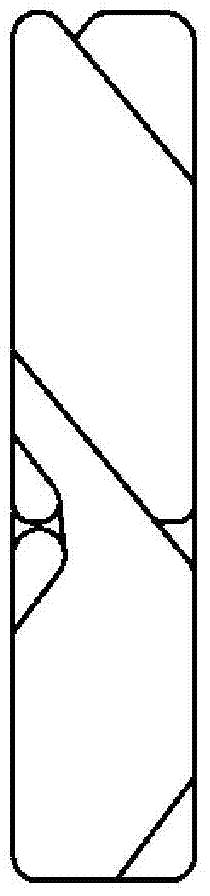

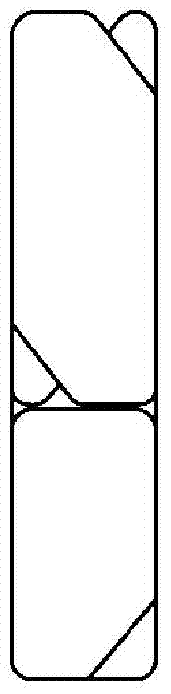

[0029] A plate condenser with liquid separation function, such as Figure 1-7 As shown, it includes a front compression plate 1, a rear compression plate 2 and an intermediate heat exchange module, the front compression plate and the rear compression plate are respectively installed on both sides of the intermediate heat exchange module; the intermediate heat exchange module A cooling water heat exchange flow channel and a steam heat exchange flow channel are provided. The intermediate heat exchange module is composed of several first heat transfer plates 3 and second heat transfer plates 4 stacked sequentially, and a first gasket 5 is arranged between the first heat transfer plates 3 and the second heat transfer plates 4 and the second gasket 6, the first gasket 5 and the second gasket 6 are alternately arranged between the first heat trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com