Tempered glass ultrasonic cleaning equipment

A technology for cleaning equipment and tempered glass, applied in lighting and heating equipment, chemical instruments and methods, cleaning methods and utensils, etc., can solve problems such as uncleaned overlapping parts, small contact area, turbid cleaning solution, etc., to achieve greater Cleans the contact surface, avoids excessive impurities, and improves the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

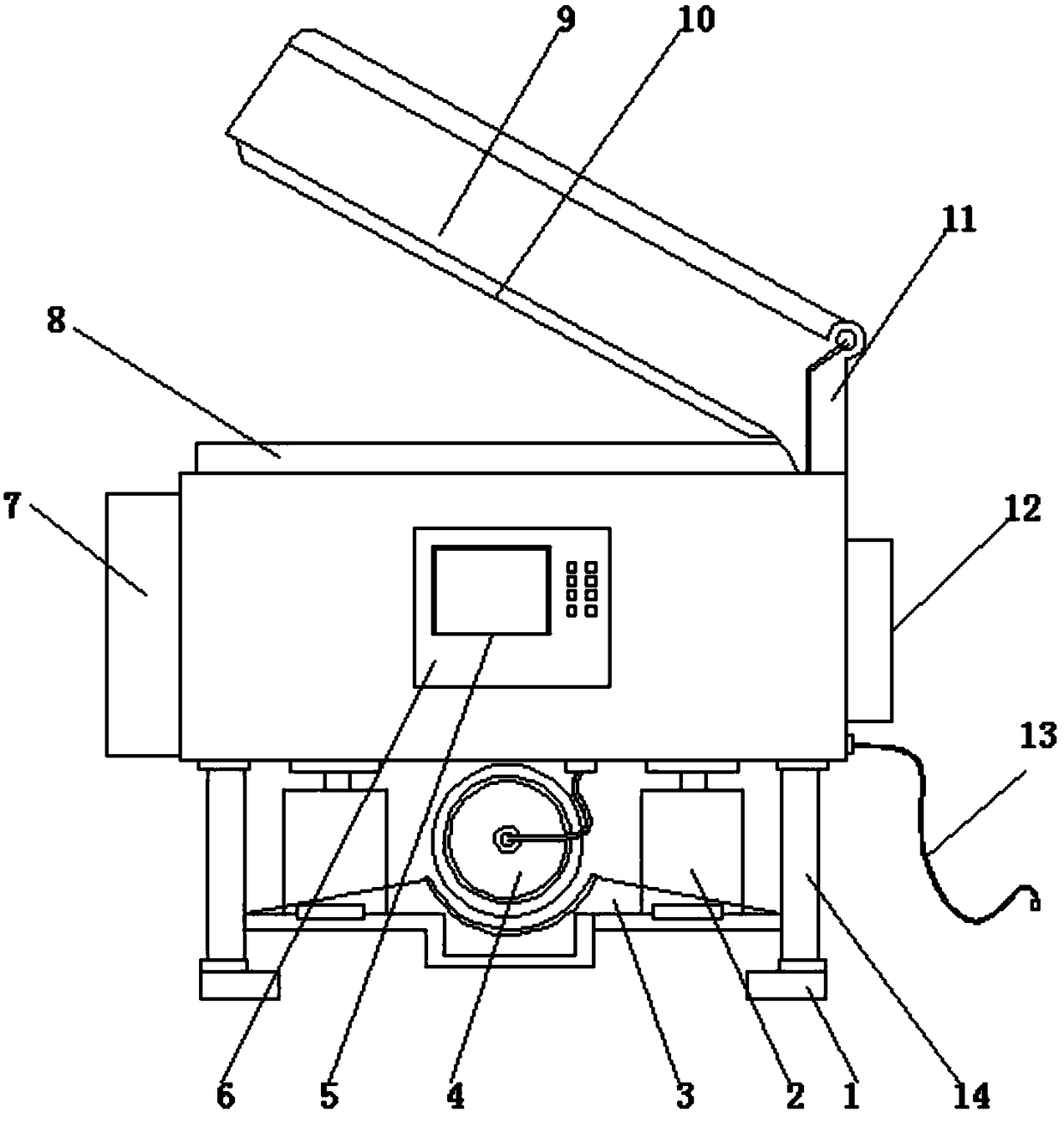

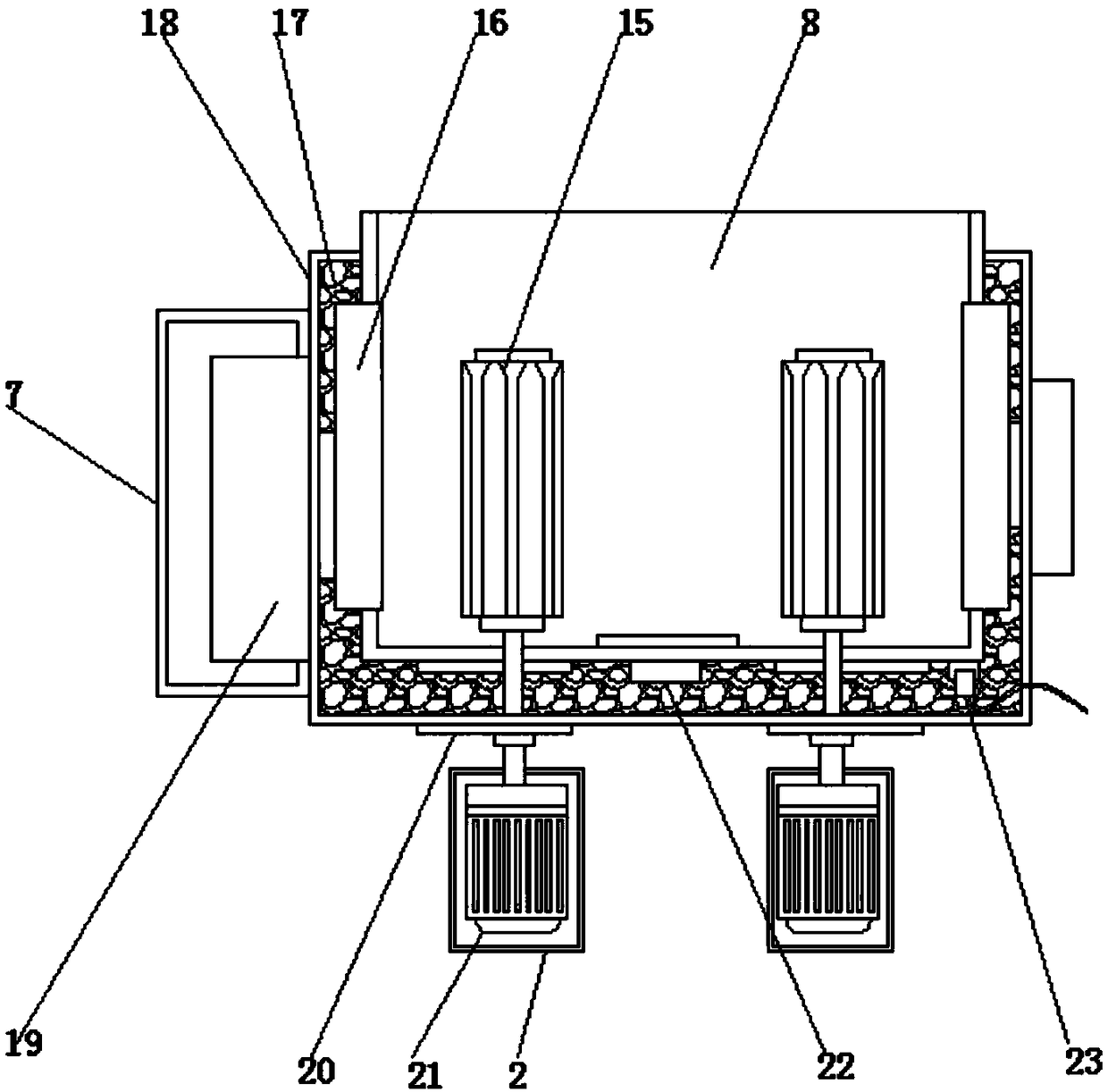

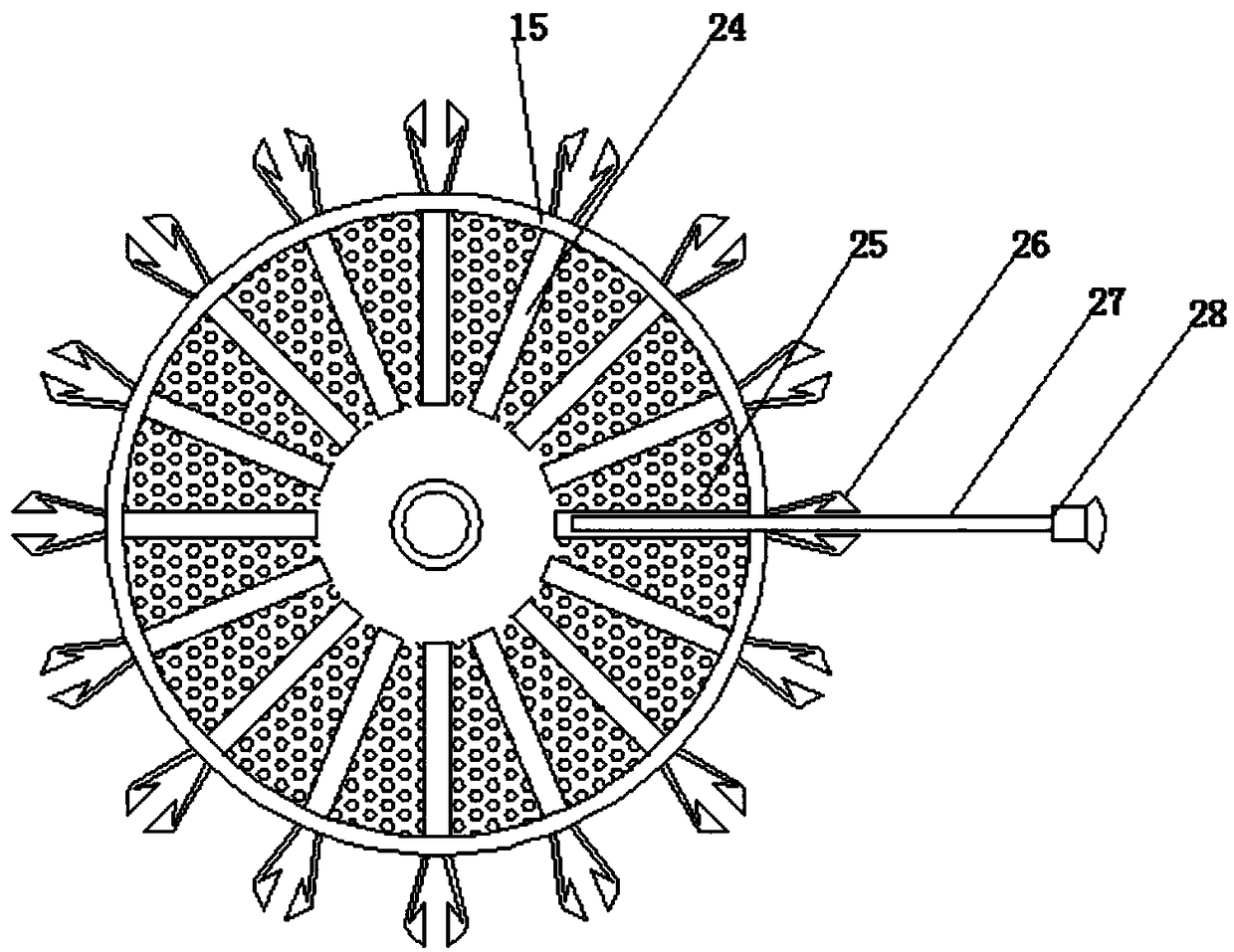

[0027] refer to Figure 1-5 , an ultrasonic cleaning device for tempered glass, comprising a base 1, the top outer wall of the base 1 is welded with a support rod 14, and the top outer wall of the support rod 14 is welded with an outer box 18, and one side outer wall of the outer box 18 is welded with a detection box 7, And the other side outer wall of outer box 18 is welded by distribution box 12, the top outer wall of outer box 18 is fixed with compression hinge bar 11 by screw near the side of distribution box 12, and the top outer wall of compression hinge bar 11 passes through The hinge is fixed with a buckle, and the top inner wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com