All-weather self-healing stretchable conductive materials and preparation method thereof

A conductive material, self-healing technology, applied to conductive materials dispersed in non-conductive inorganic materials, metal/alloy conductors, cable/conductor manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Fully dissolve 2g of γ-PGA (white powder with a molecular weight of 10-70w) and 4g of allyl glycidyl ether in 25mL of deionized water, adjust the pH to 2-4 with acetic acid, stir at room temperature, and react for 36 hours Afterwards, extract three times with dichloromethane, collect the upper layer γ-PGAA aqueous solution, and prepare 50 mg / mL γ-PGAA aqueous solution.

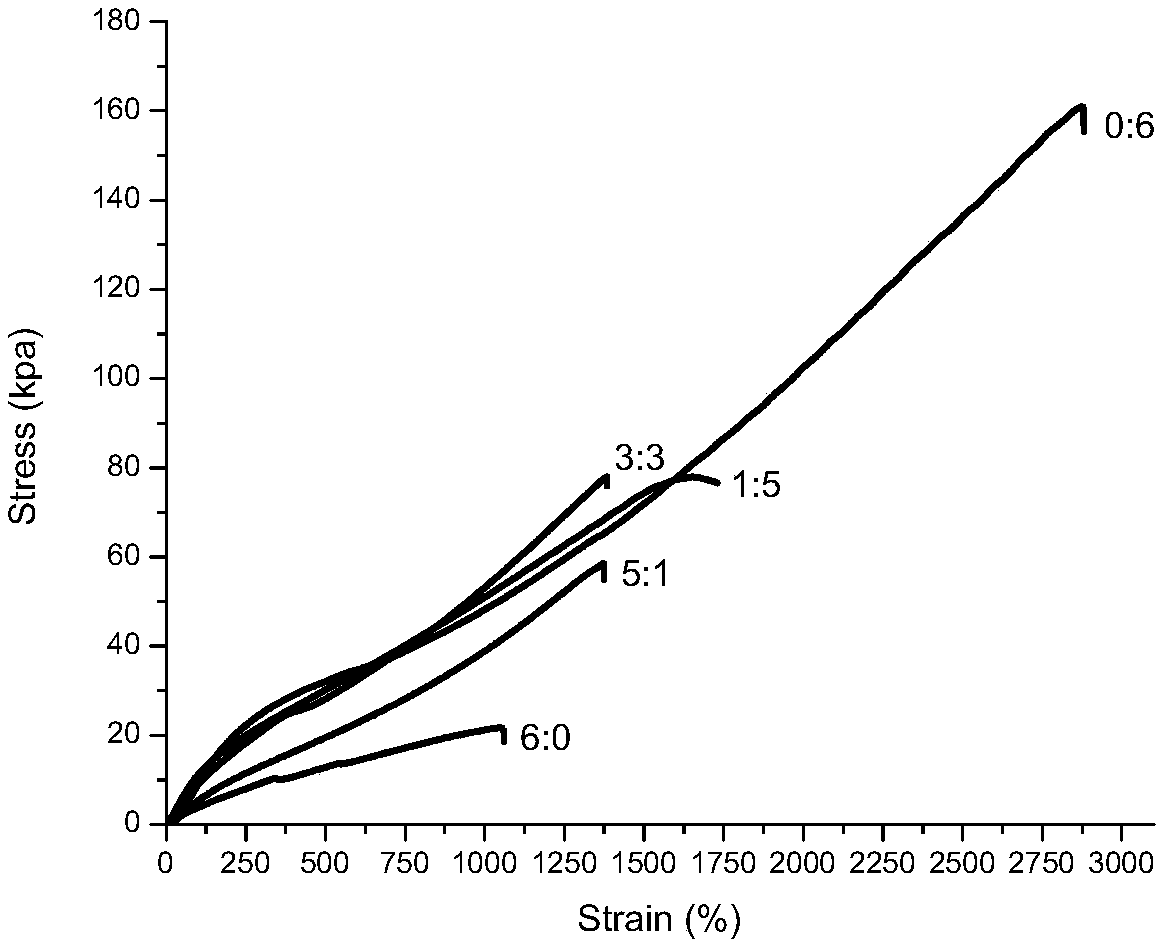

[0031] (2) Take 2g of acrylic acid, 4mL of γ-PGAA solution, 4mg of MBAA, 40mg of APS, 0.056g of FeCl 3 .6H 2 O, GC:H at volume ratios of 0:6, 1:5, 3:3, 5:1, 6:0 2 Mix well in O, pass nitrogen gas for 30 minutes to remove the gas in the solution, and polymerize at 60°C for 30 minutes to obtain composite hydrogels with different solvent volume ratios. When the content of γ-PGAA solution is 0mL, FeCl 3 .6H 2 O content is 0mg, GC:H 2 When the volume ratio of O is 0:6, it is labeled as PAA hydrogel; when the content of γ-PGAA solution is 4mL, FeCl 3 .6H 2 O content is 0mg, GC:H 2When the volume r...

Embodiment 2

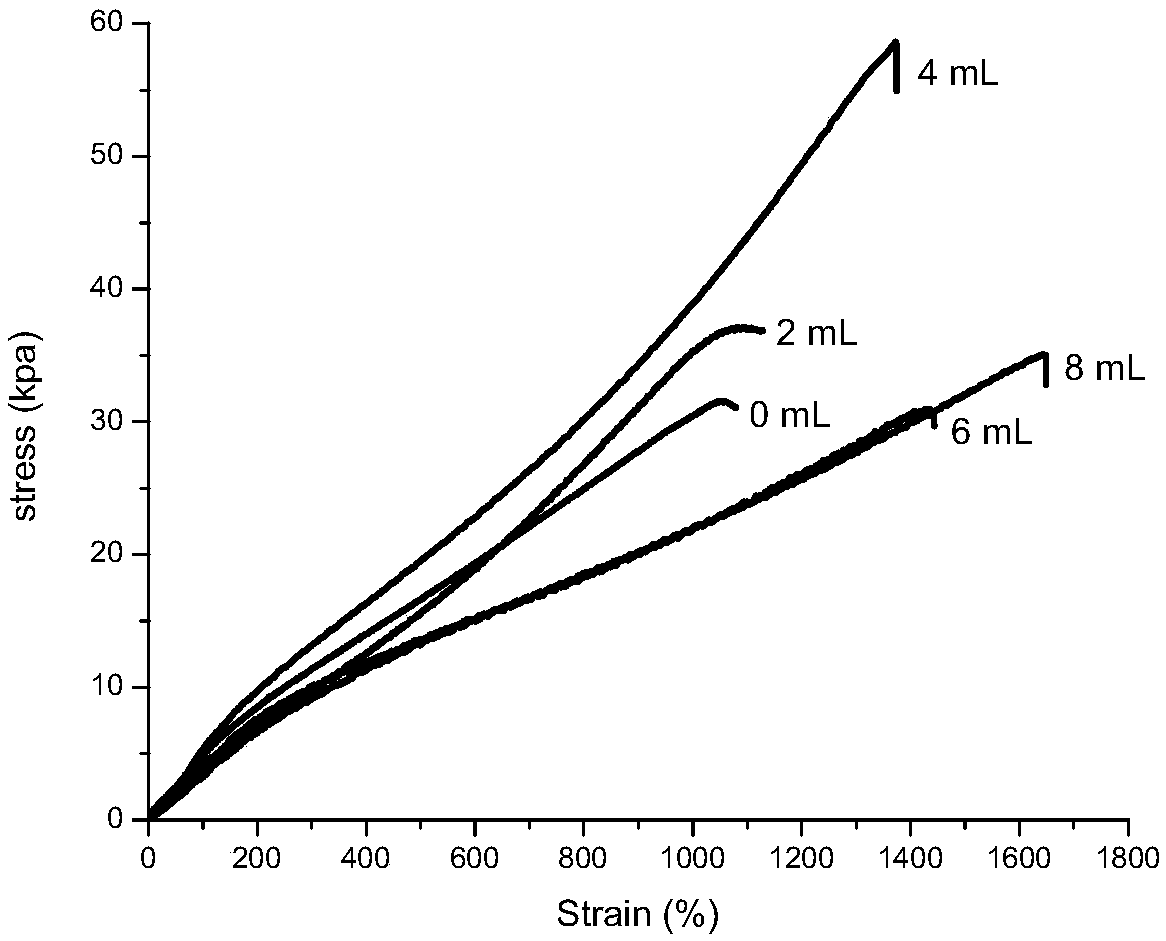

[0033] Change embodiment 1 step (2) to get 2g acrylic acid, 4mg MBAA, 40mg APS, 0.056g FeCl 3 .6H 2 O, in GC:H 2 The volume ratio of O is 5:1, the γ-PGAA solutions are 0mL, 2mL, 4mL, 6mL, and 8mL respectively. After the solutions are mixed evenly, the gas in the solution is removed by passing nitrogen gas for 30 minutes, and the polymerization reaction occurs at 60°C for 30 minutes. For composite hydrogels with different γ-PGAA contents, the rest of the steps are the same as in Example 1.

Embodiment 3

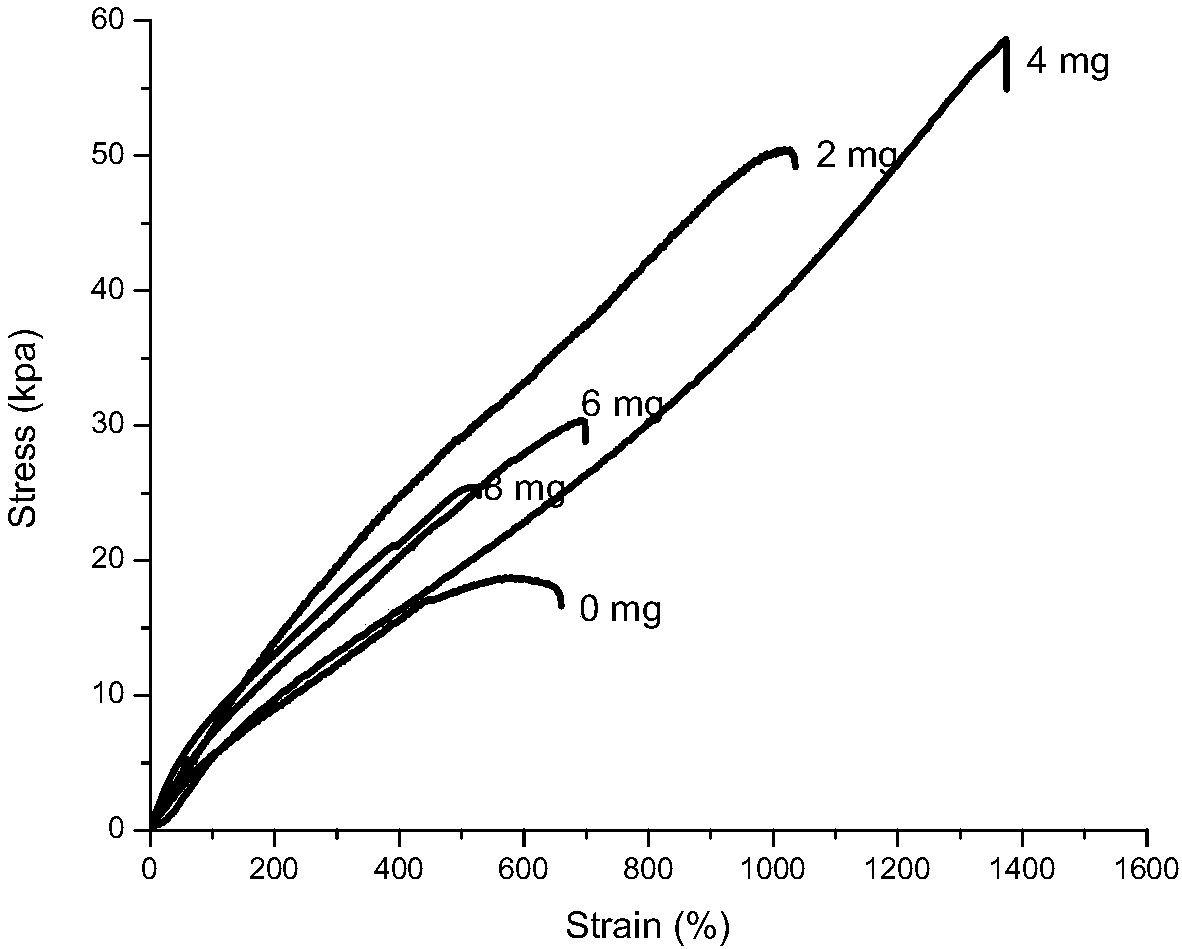

[0035] Change Example 1 step (2) to get 2g acrylic acid, 4mL γ-PGAA, 40mg APS, 0.056g FeCl 3 .6H 2 O, in GC:H 2 The volume ratio of O is 5:1, and the mass of MBAA is 0mg, 2mg, 4mg, 6mg, 8mg respectively. After the solution is mixed evenly, the gas in the solution is removed by passing nitrogen gas for 30 minutes, and the polymerization reaction takes place at 60°C for 30 minutes to obtain different Polyacrylic acid and polyglutamic acid composite hydrogels with MBAA content. All the other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com