Manufacturing method of miniature X-ray array combined refracting lens integrated assembly

A technology for combining refractive lenses and a manufacturing method is applied in the field of manufacturing a new type of X-ray array combined refractive lens integrated components, which can solve the problems of large size, insufficient resolution of micro-area, and insufficient detection sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with the accompanying drawings.

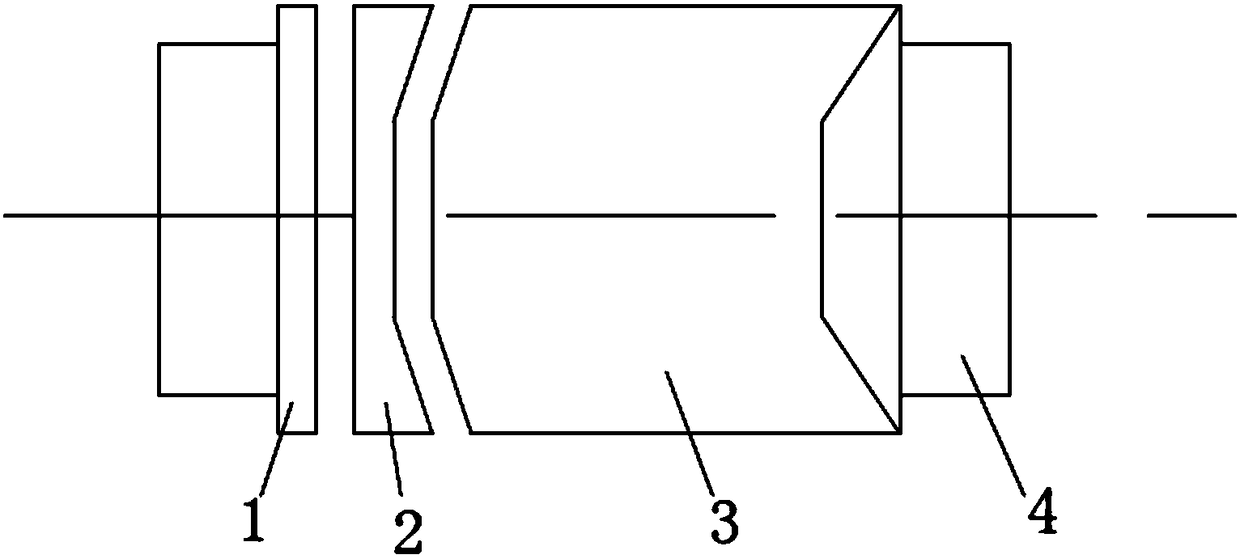

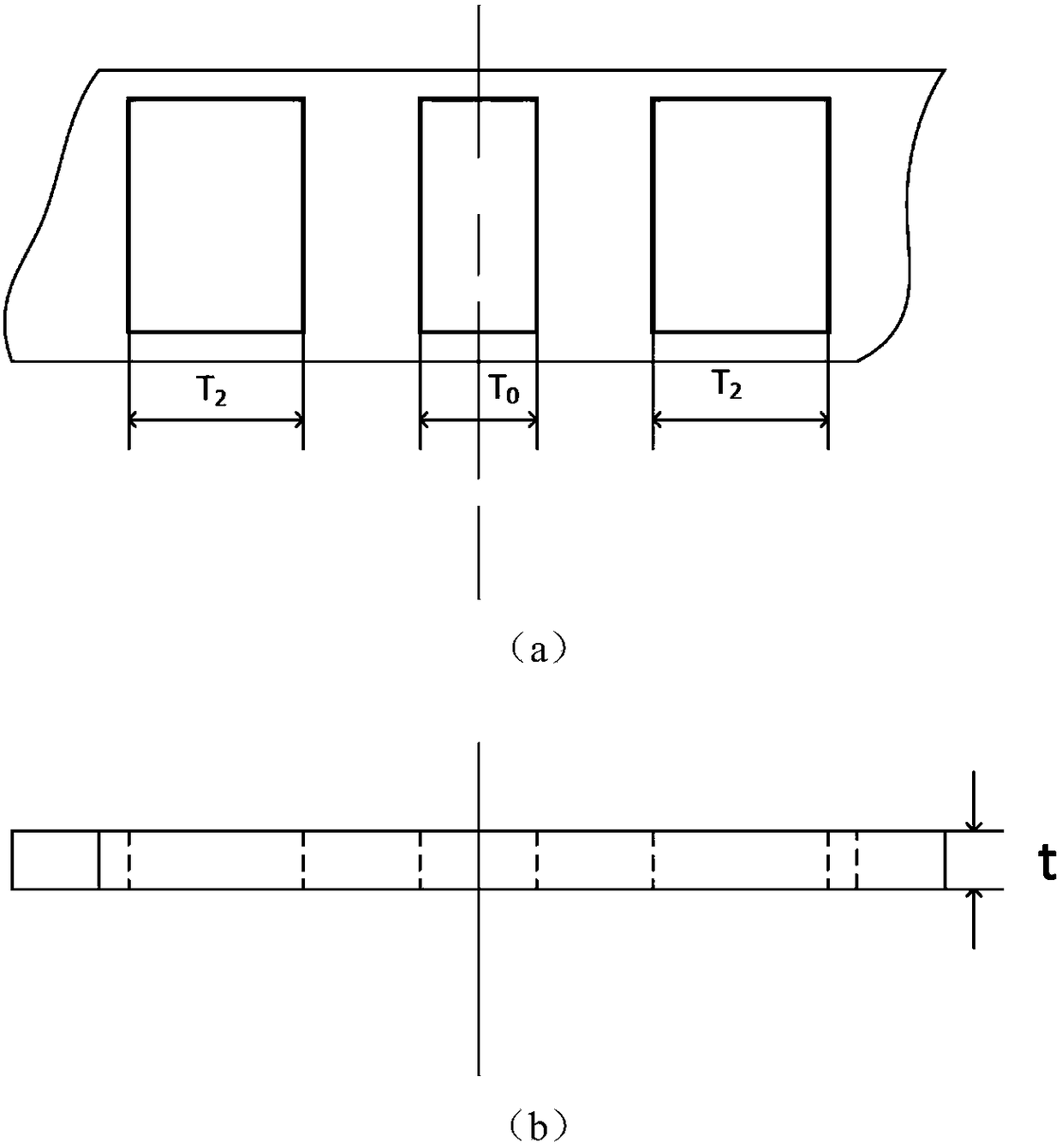

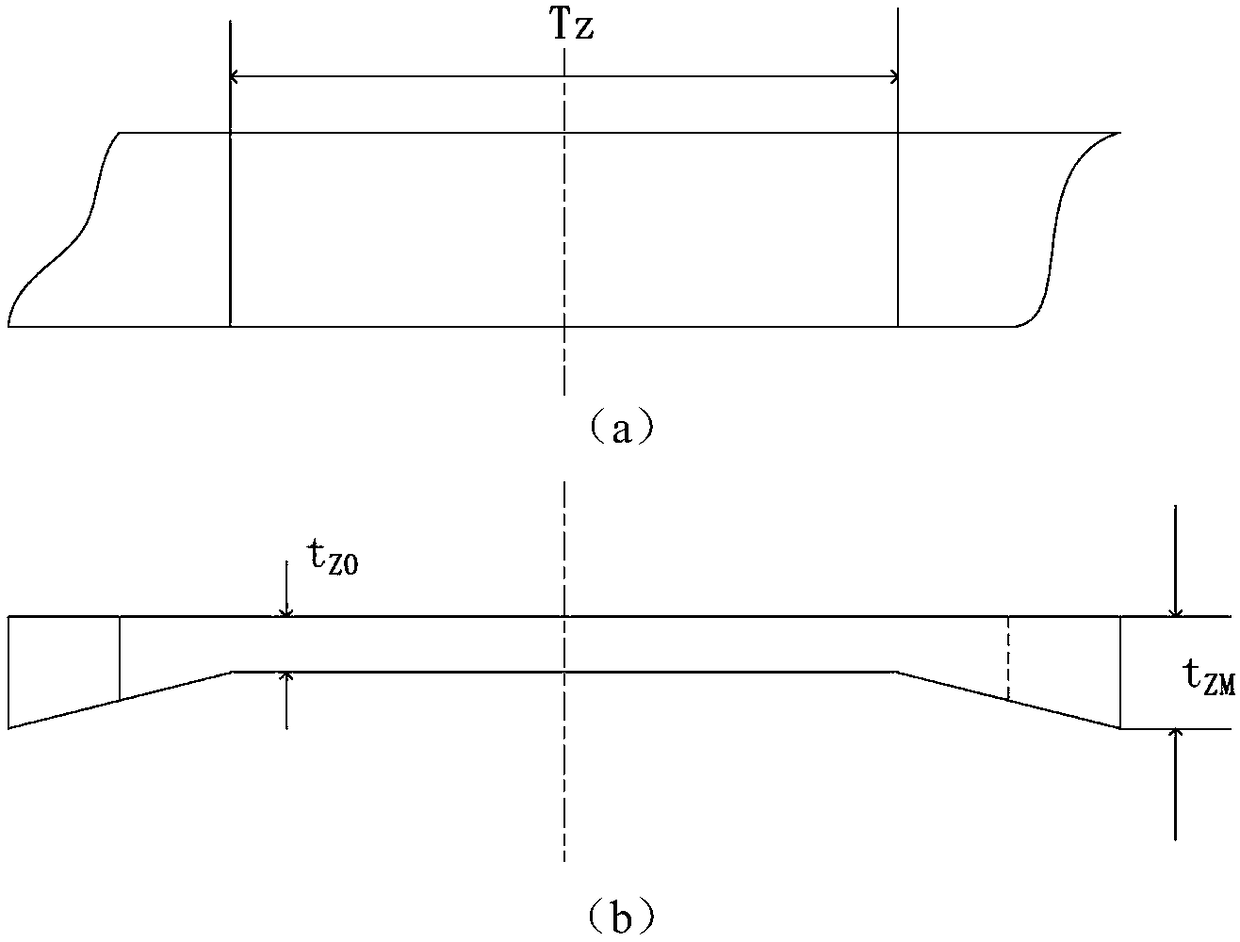

[0069] refer to Figure 1 ~ Figure 4 , a method for manufacturing and assembling a miniaturized X-ray array combined refracting lens assembly, the miniaturized X-ray array combined refracting lens integrated assembly includes an X-ray diaphragm, an X-ray refractor, an X-ray array combined lens and a component carrier stage, the X-ray aperture performs the first shaping and filtering, and the first shaping refers to shaping the incident X-ray light wave according to the numerical aperture of the X-ray array combination refracting lens; the filtering means The incident X-ray light wave is split to form multiple sub-beams, and the number of sub-beams is the same as the number of combined refracting lenses in the X-ray array combined refracting lens. The X-ray light wave that has been split into multiple sub-beams enters the X-ray refractor, and the beam is reshaped for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com