Nuclear fuel reprocessing plant plutonium product transfer device

A transfer device and nuclear fuel technology, applied in nuclear engineering, reactors, shielding, etc., can solve the problems of insufficient shielding effect, high dose of exposure to personnel, and low dose of exposure, so as to reduce the risk of gamma radiation and reduce the dose of occupational exposure , Improve the effect of shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

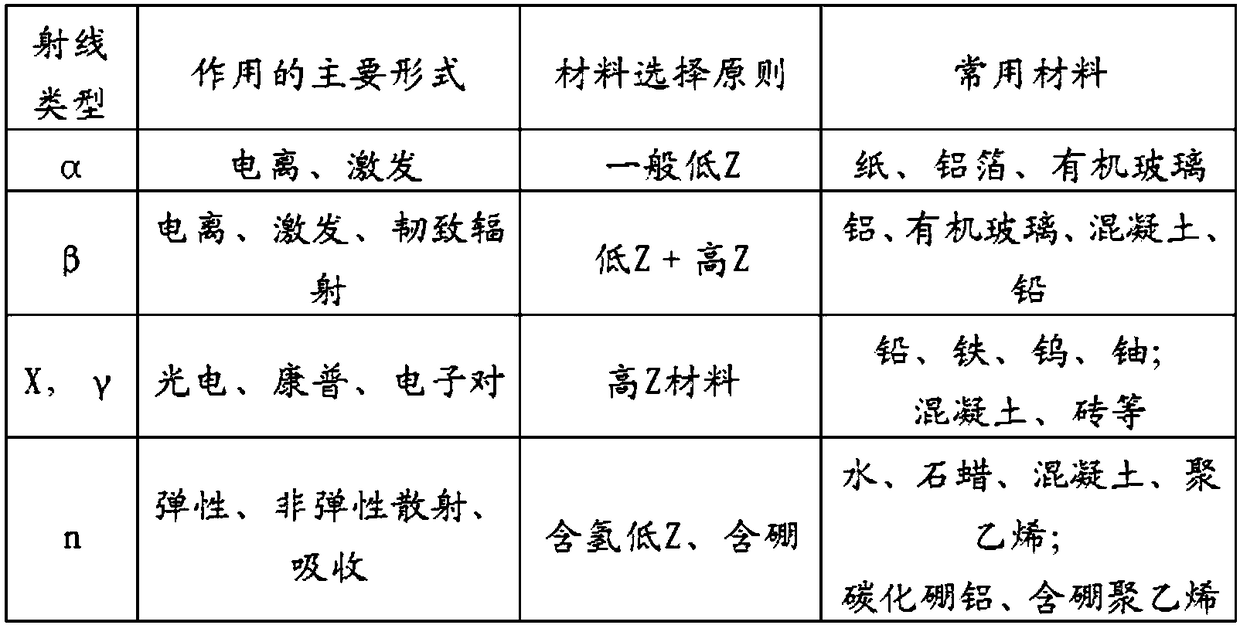

[0028] Combined with the material selection in Table 1, it is necessary to select a combination of hydrogen-containing low Z + high Z to shield α particles, β rays, γ rays and neutrons, and considering the stability of the device structure, a three-layer structure is adopted .

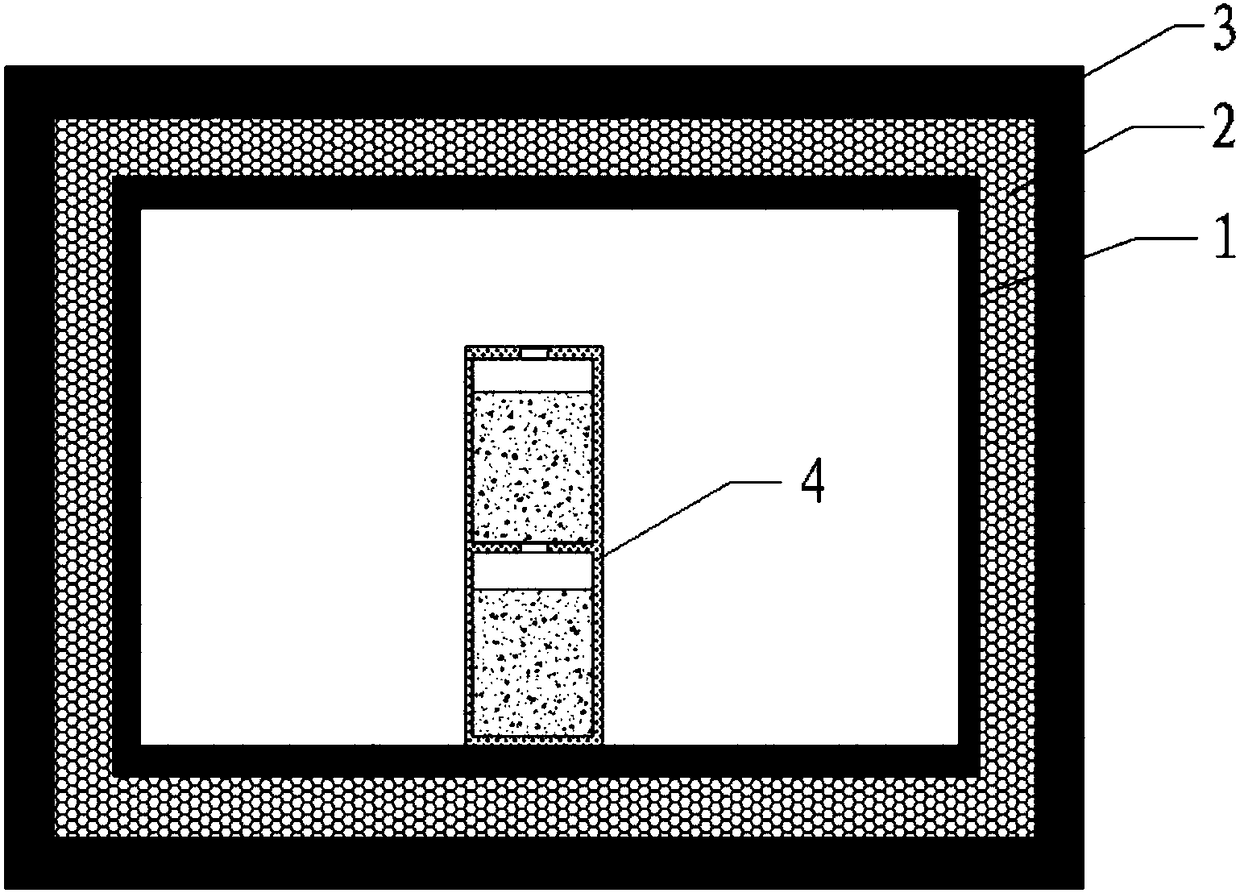

[0029] After preliminary calculation and analysis of radiation shielding and referring to the current design of typical plutonium product cups, the three-layer shielding structure design adopted by this transfer device is as follows: figure 2 As shown, the shielding layer of a plutonium product transfer device in a nuclear fuel reprocessing plant provided by the present invention is composed of a first stainless steel shielding layer 1 on the innermost side, a second stainless steel shielding layer 3 on the outermost side, and a stainless steel shielding layer located on the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com