Corrosion test method for high voltage live ertv antifouling flashover coatings

An anti-pollution flashover coating, high-voltage charging technology, applied in the fields of weather resistance/light resistance/corrosion resistance, measurement of electricity, analysis of materials, etc., can solve the problem that insulators are far from each other, and achieve simple production, convenient purchase and use, and good reproduction. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

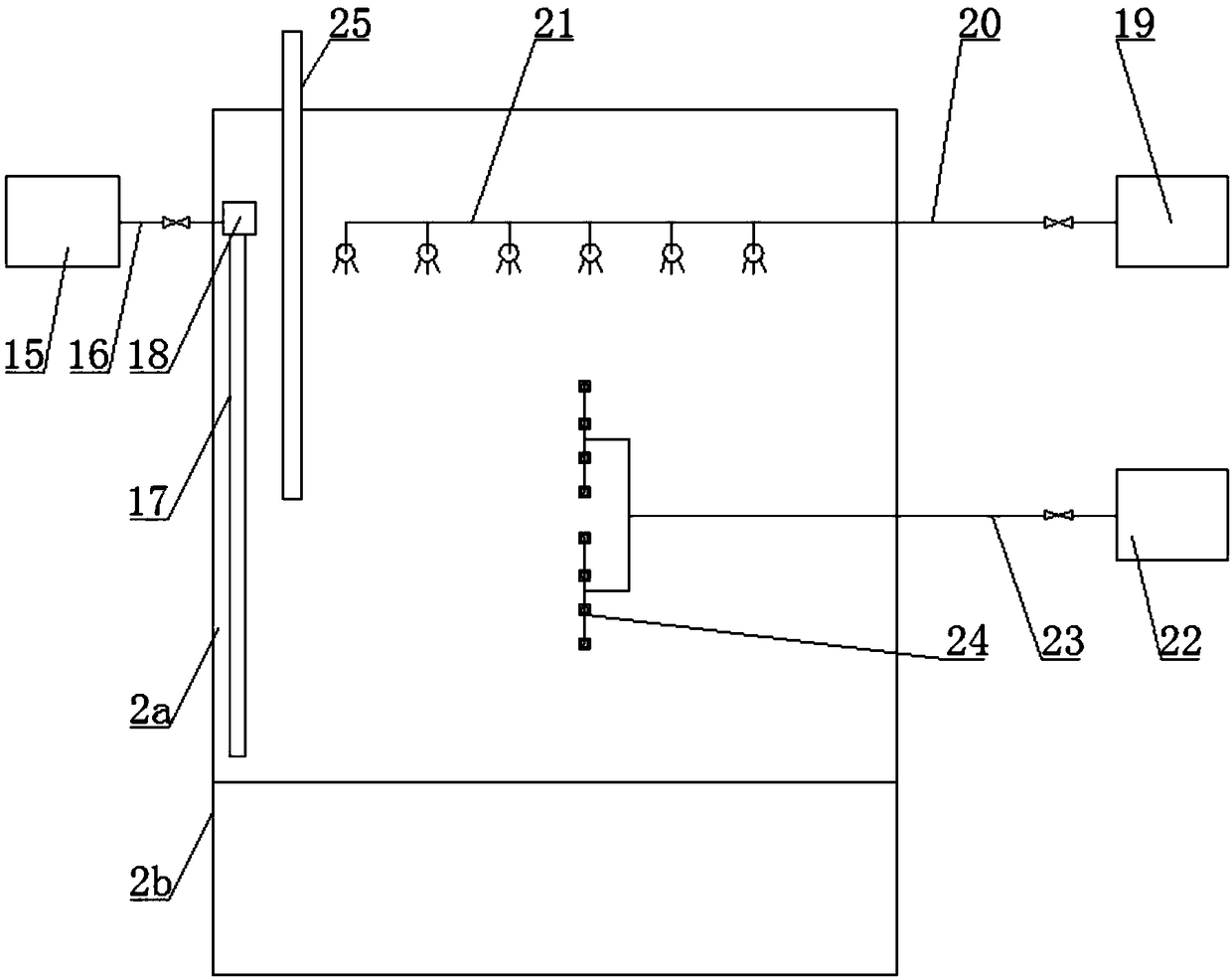

[0025] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

[0026] As shown in the figure, the corrosion test method of a kind of high-voltage electrified ERTV anti-fouling flashover coating provided by the present invention comprises the following steps: first, make the counter force test bench 1 of L-shaped structure, and this counter force test bench 1 uses C40 concrete pouring It is formed by laying double-layer steel mesh inside, and pre-embedded steel plates 9 on the side walls; then, the reaction box 2 is set on the inner side of the reaction test bench 1, and the high-voltage charged ERTV anti-pollution flashover coating is coated The tension insulator 3 is put into the reaction box 2, and one end passes through the short...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com