Hydraulic cylinder frictional compensation control method study

A control method and friction compensation technology, applied in the field of pressure control systems, can solve problems such as hydraulic oil flow control, loss, oil leakage, etc., to resist the influence of friction, improve tracking accuracy, and operate effectively and reasonably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific structure and implementation mode of the present invention will be further described below in conjunction with the accompanying drawings.

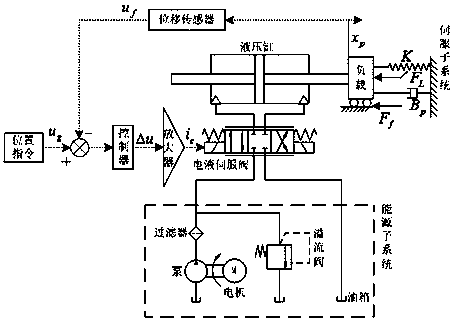

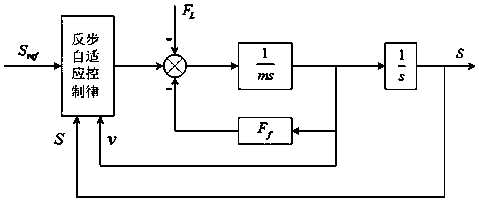

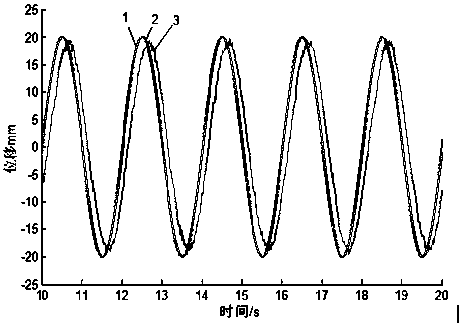

[0016] combine Figures 1 to 4 , the present invention relates to a hydraulic cylinder friction compensation device and control method, which belongs to the field of hydraulic control system, and its composition includes: motor, pump, filter, electro-hydraulic servo valve, amplifier, controller, position commander, displacement sensor, hydraulic pressure Cylinder, load, relief valve and other components. The motor controls the pump to supply oil to the electro-hydraulic servo valve through the filter, one end of the filter returns to the oil tank through the overflow valve, and the other end supplies oil to the hydraulic cylinder through the oil inlet of the electro-hydraulic servo valve to push the piston rod of the hydraulic cylinder to move. After the position commander receives the command, it inputs the signal cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com