A kind of composite tile and its production process

A technology for ceramic tiles and full-body tiles, applied in the field of ceramic tiles, can solve the problems of heavy weight, inconvenient handling, easy falling off and shifting of tiles, lack of drainage function, etc., to achieve the effects of improving living comfort, reducing quality, and accelerating water loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

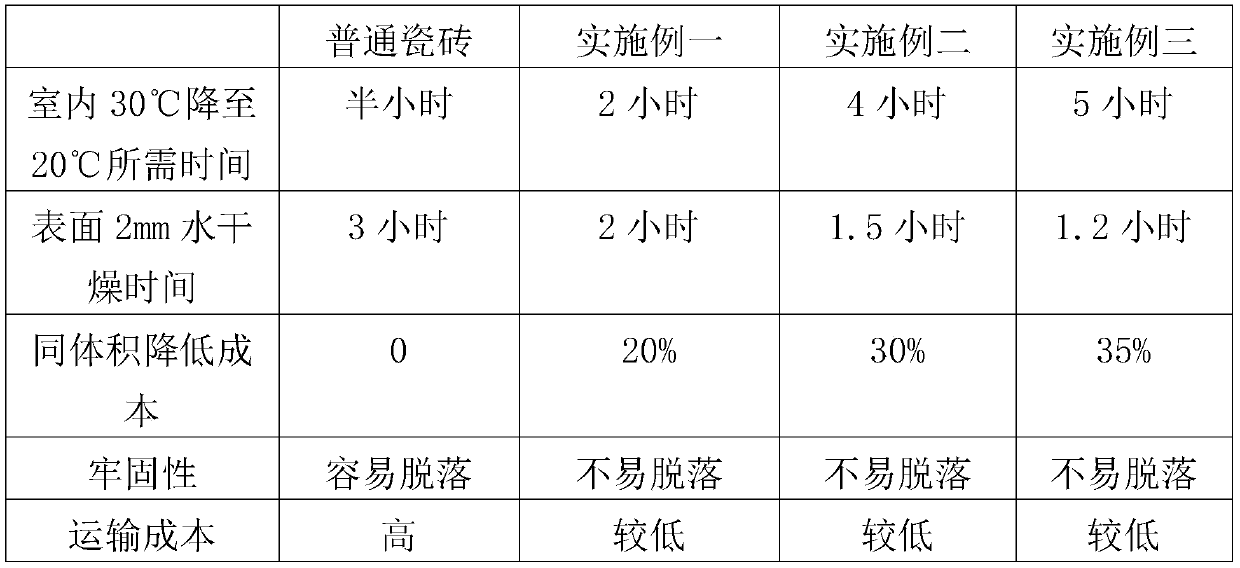

Embodiment 1

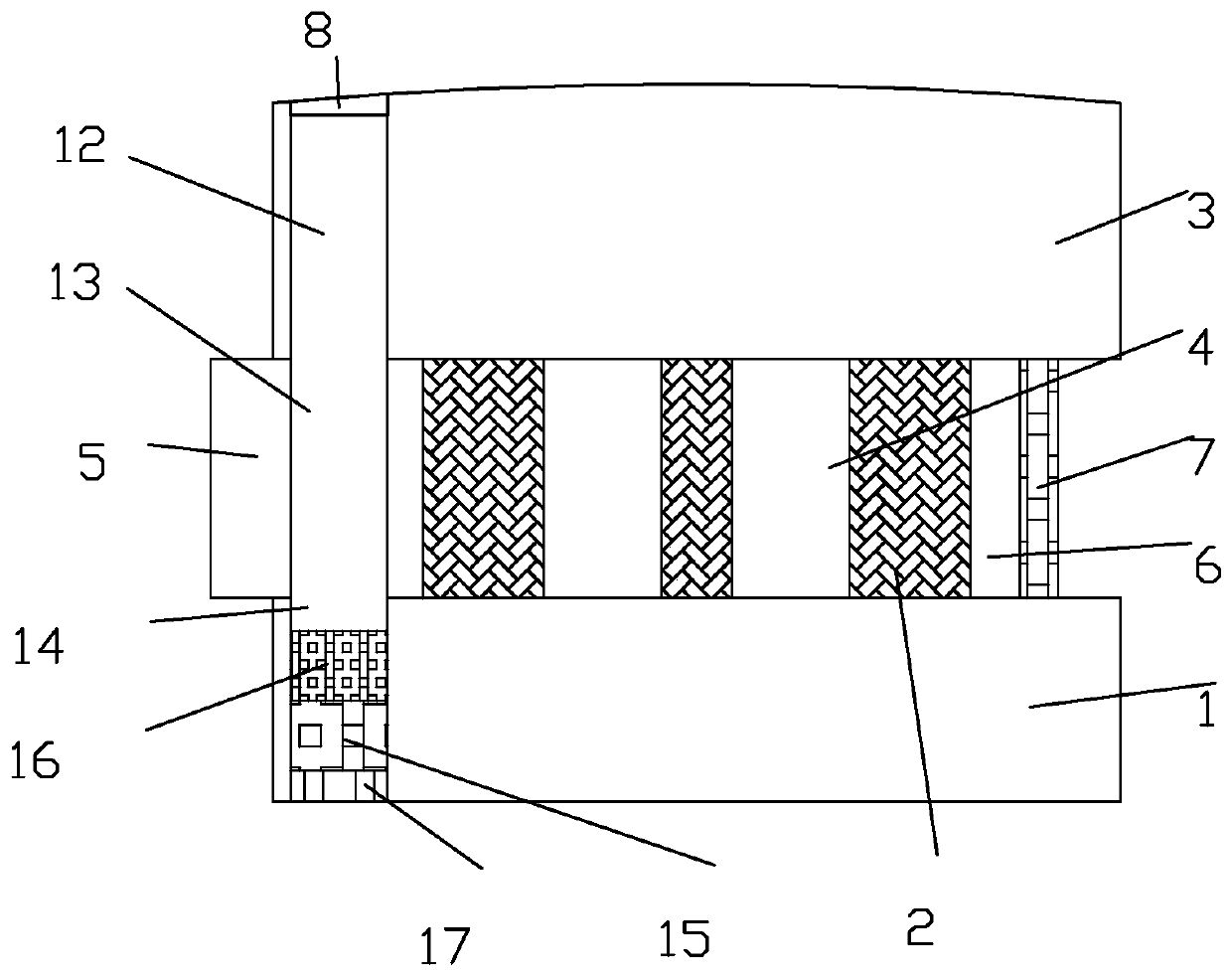

[0030] A composite ceramic tile, comprising a lower board 1, characterized in that: the top of the lower board 1 is fixedly connected with an insulation layer 2, the top of the insulation layer 2 is fixedly connected with an upper board 3, and the middle position between the lower board 1 and the upper board 3 The support column 4 is fixedly connected, the support column 4 runs through the insulation layer 2, the side of the insulation layer 2 between the lower plate 1 and the upper plate 3 is fixedly connected with a bump 5, and the distance between the lower plate 1 and the upper plate 3 is far away from the bump One side of 5 is fixedly connected with rubber pad 7 by baffle plate 6.

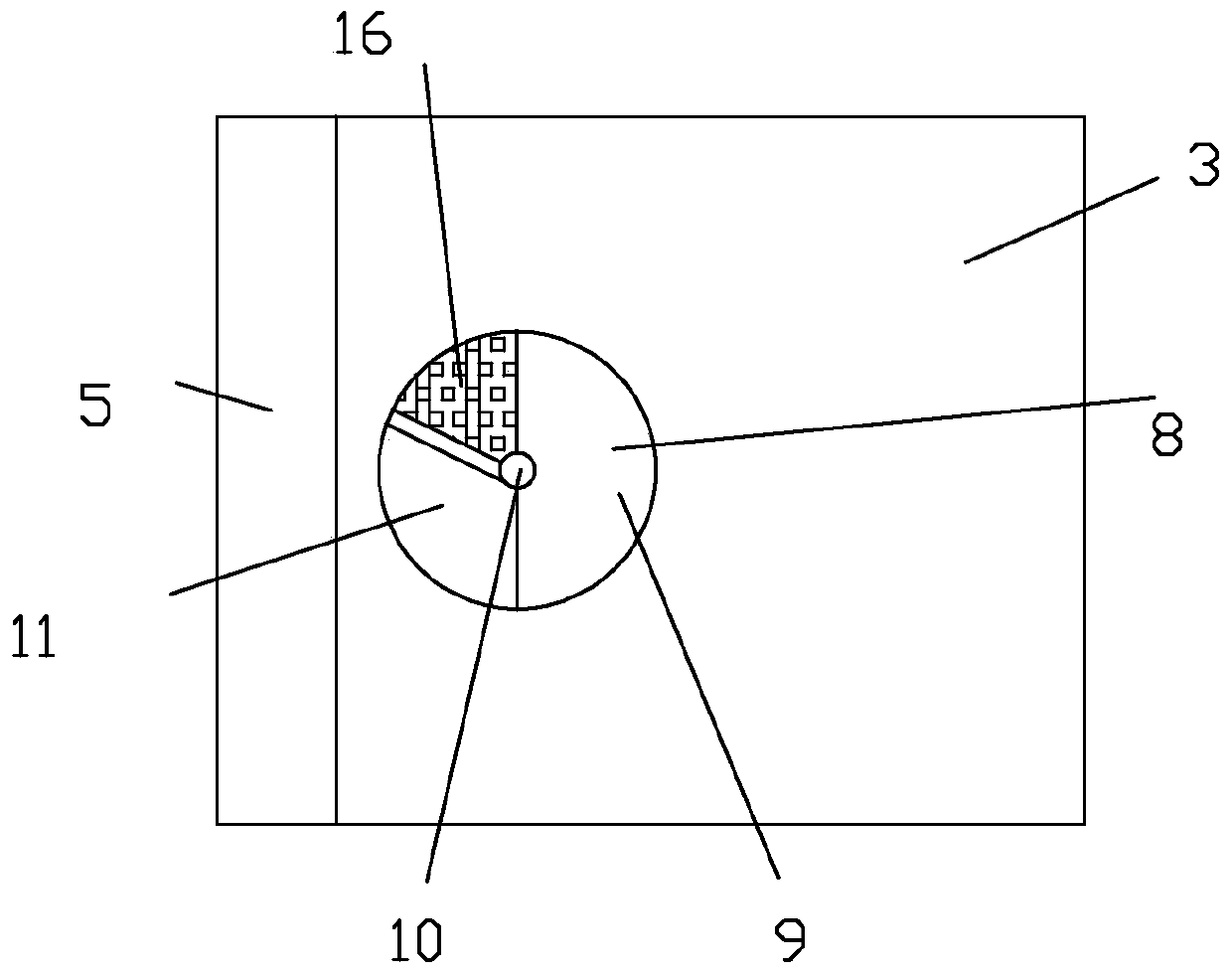

[0031] One side of the top of the upper plate 3 is provided with a water inlet 8, and one side of the water inlet 8 is fixedly connected with a fixed plate 9, and the middle position of the fixed plate 9 is connected with a rotating plate 11 through a rotating rod 10, and the bottom of the uppe...

Embodiment 2

[0046] A composite ceramic tile, comprising a lower board 1, characterized in that: the top of the lower board 1 is fixedly connected with an insulation layer 2, the top of the insulation layer 2 is fixedly connected with an upper board 3, and the middle position between the lower board 1 and the upper board 3 The support column 4 is fixedly connected, the support column 4 runs through the insulation layer 2, the side of the insulation layer 2 between the lower plate 1 and the upper plate 3 is fixedly connected with a bump 5, and the distance between the lower plate 1 and the upper plate 3 is far away from the bump One side of 5 is fixedly connected with rubber pad 7 by baffle plate 6.

[0047] One side of the top of the upper plate 3 is provided with a water inlet 8, and one side of the water inlet 8 is fixedly connected with a fixed plate 9, and the middle position of the fixed plate 9 is connected with a rotating plate 11 through a rotating rod 10, and the bottom of the uppe...

Embodiment 3

[0062] A composite ceramic tile, comprising a lower board 1, characterized in that: the top of the lower board 1 is fixedly connected with an insulation layer 2, the top of the insulation layer 2 is fixedly connected with an upper board 3, and the middle position between the lower board 1 and the upper board 3 The support column 4 is fixedly connected, the support column 4 runs through the insulation layer 2, the side of the insulation layer 2 between the lower plate 1 and the upper plate 3 is fixedly connected with a bump 5, and the distance between the lower plate 1 and the upper plate 3 is far away from the bump One side of 5 is fixedly connected with rubber pad 7 by baffle plate 6.

[0063] One side of the top of the upper plate 3 is provided with a water inlet 8, and one side of the water inlet 8 is fixedly connected with a fixed plate 9, and the middle position of the fixed plate 9 is connected with a rotating plate 11 through a rotating rod 10, and the bottom of the uppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com