Separate steel grid shear wall based on T-shaped steel members

A technology of T-shaped steel and shear walls, which is applied in the direction of building components, walls, and building structures, can solve the problems of reducing lateral bearing capacity, deformation of thin steel plates outside the surface, and increasing the force burden of steel plate walls, so as to ensure accurate and high efficiency, reduced calculation difficulty and time-consuming, convenient transportation and on-site installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

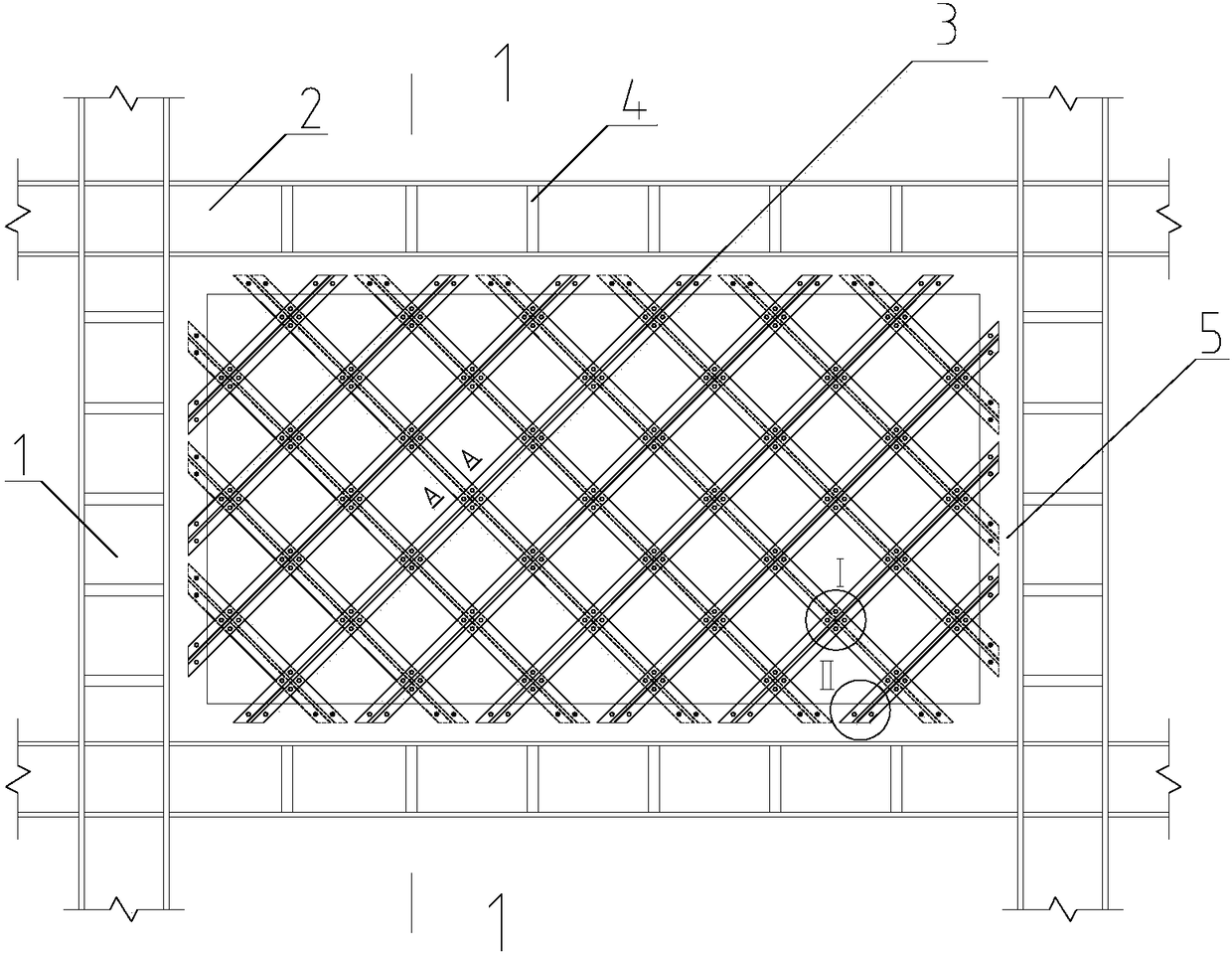

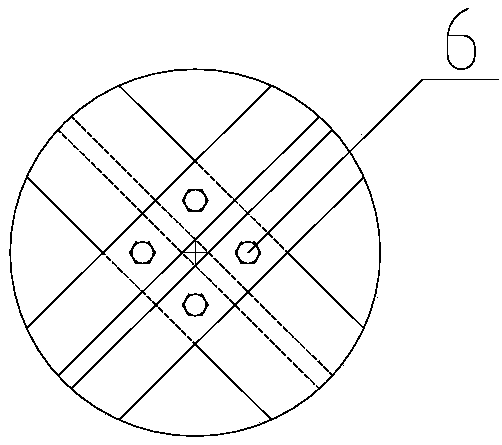

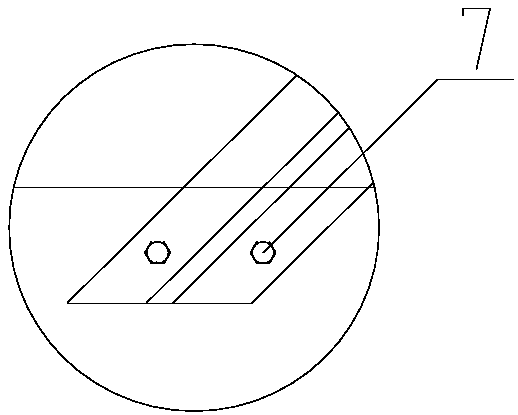

[0028] see Figure 1 to Figure 5 , a separated steel grid shear wall based on T-shaped steel members, the basic idea is to discretize the embedded steel plates into T-shaped steel members 3 arranged in two-way separation, and the T-shaped steel members 3 are mixed according to the existing steel plate shear wall The basic principle of the bar system simplified calculation model is set, the T-shaped steel member 3 is provided with a flange plate 3-1 and a web 3-2, the flange plate 3-1 is equivalent to a steel plate wall, and its web 3-2 is equivalent to Stiffeners.

[0029] In this embodiment, the shear wall adopts a grid structure. More specifically, the grid structure is formed by connecting a plurality of T-shaped steel members 3 arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com