a brewing device

A technology of a rotating shaft and a rack is applied in the field of brewing devices, which can solve the problems of material waste, affecting liquor production, and lack of wine tank cleaning devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Further detailed explanation through specific implementation mode below:

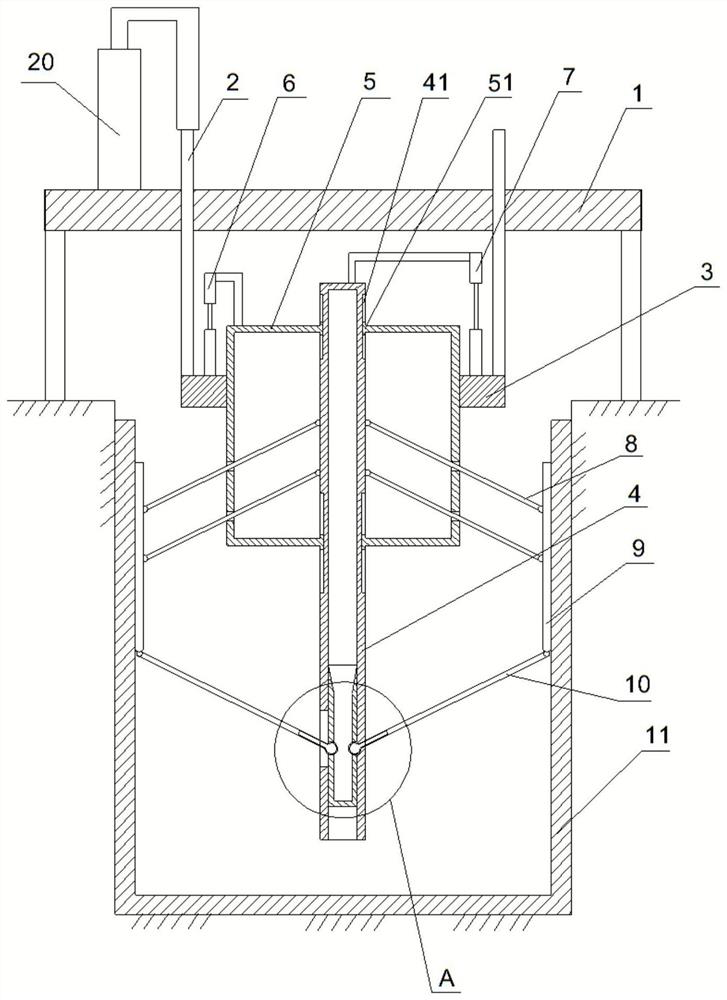

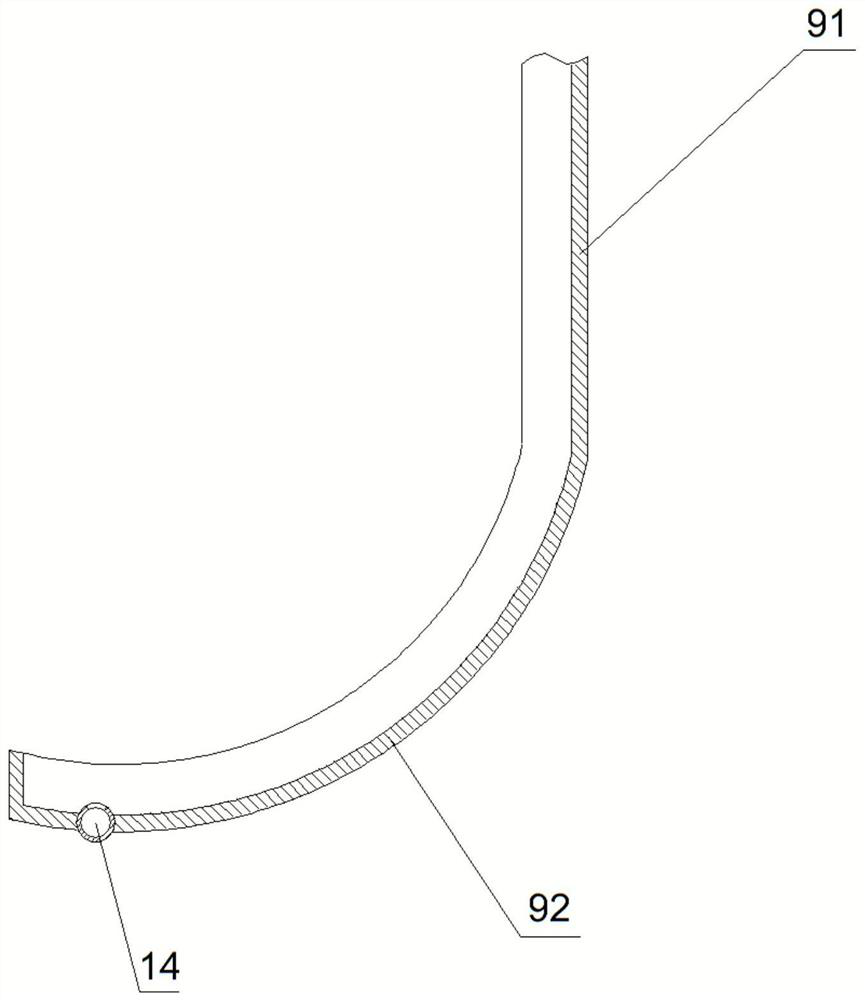

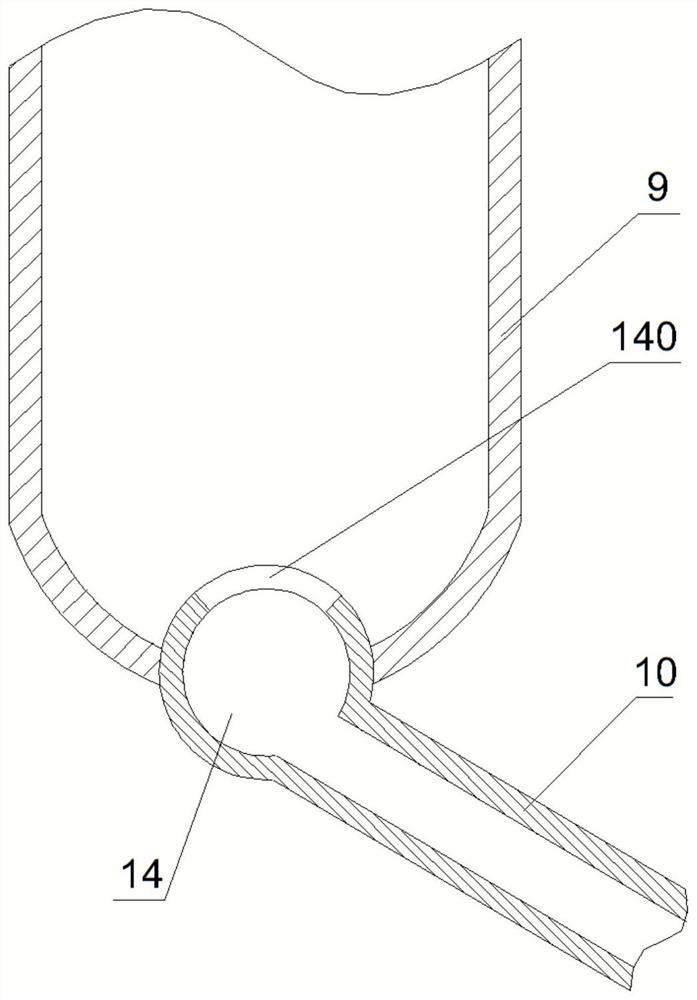

[0022] The reference signs in the drawings of the description include: frame 1, push rod 2, support base 3, rotating shaft 4, mounting hole 40, chute 41, sleeve 5, slider 51, second electric push rod 6, first Electric push rod 7, supporting connecting rod 8, scraper 9, straight part 91, arc part 92, pipe 10, wine vat 11, sliding body 12, second connecting ball 13, wine grains outlet 130, first connecting ball 14 140 for the entrance of wine grains.

[0023] like figure 1 As shown, the brewing device of this embodiment includes a frame 1, a push rod 2 is vertically slidably connected to the frame 1, a hydraulic cylinder 20 is installed on the frame 1, and the output rod of the hydraulic cylinder 20 is connected to the top of the push rod 2. Fixed connection, the bottom end of the push rod 2 is fixedly connected with a support base 3, and the support base 3 is rotatably connected with a sleeve 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com