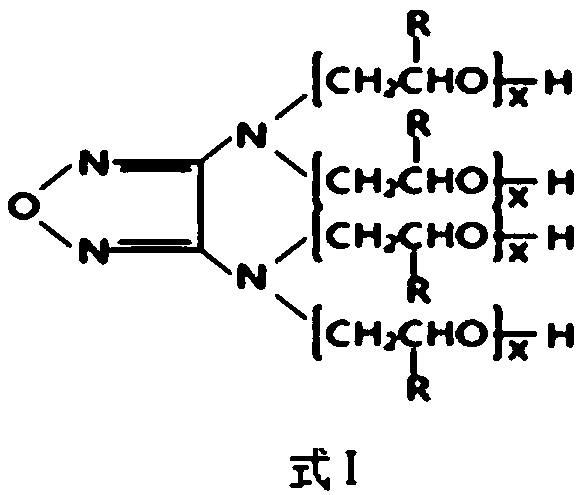

3,4-diaminofurazan polyether polyol, preparation method, rigid polyurethane foam prepared from 3,4-diaminofurazan polyether polyol and preparation method

A technology of polyether polyol and polyurethane rigid foam is applied in the fields of 3,4-diaminofuroxa polyether polyol and preparation, low density and low conductivity 134a system rigid polyurethane foam and preparation thereof, and can solve the problem of HFC-134a. It can be widely used, prone to volatilization and escape, affecting the overall performance of the foam, etc., to achieve the effect of weakening the autocatalytic effect, benefiting strength and fluidity, optimizing strength and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

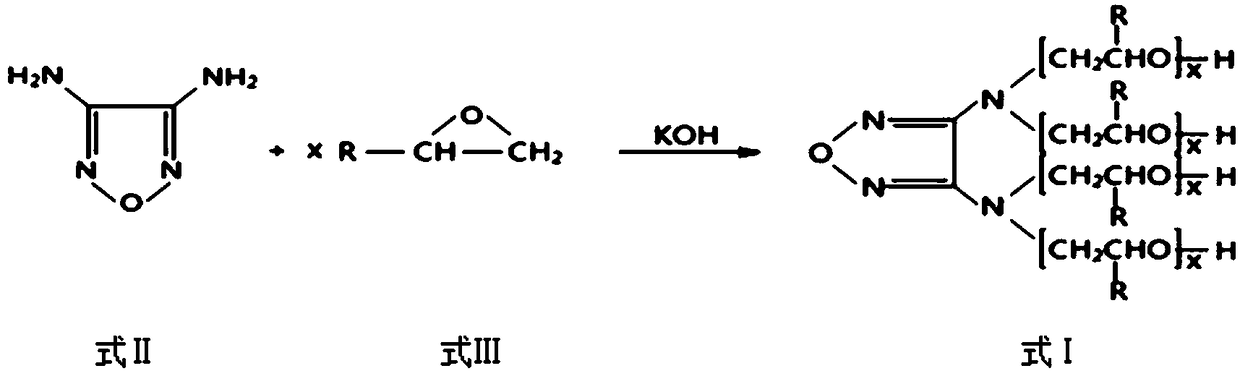

[0064] A kind of preparation method of 3,4-diaminofurazol polyether polyol, the steps are:

[0065] 1) Add water (135g) and 3,4-diaminofurazol (530g) into the reaction kettle, replace with nitrogen to test pressure, start stirring and heat to 90°C to obtain 3,4-diaminofurazol aqueous solution, and then press the flow rate Add 1035g propylene oxide at 700g / h, autocatalyze the reaction for 1h, then raise the temperature to 115°C and carry out the aging reaction for 1h;

[0066] 2) Add 20g (concentration: 50wt%) aqueous potassium hydroxide solution to the system in step 1), dehydrate in vacuum at 110°C for 2h, then meter the remaining 970g of propylene oxide at a flow rate of 600g / h, continue the reaction for 1h, and then heat up to Reaction at 120°C for 1 hour;

[0067] 3) At this time, 35 g of phosphoric acid aqueous solution with a concentration of 50 wt % was added to remove K ions to obtain 3,4-diaminofurazal polyether polyol with a hydroxyl value of 346 mgKOH / g and a funct...

Embodiment 2

[0069] The preparation method of 3,4-diaminofurazol polyether polyol, the steps are:

[0070] 1) Add water (135g) and 3,4-diaminofurazol (530g) into the reaction kettle, replace with nitrogen to test the pressure, start stirring and heat to 90°C, and keep it for 1 hour to get 3,4-diaminofurazol Aqueous solution, then add 828g epoxy olefin (the mass ratio of propylene oxide to ethylene oxide is 8:2) according to the flow rate of 700g / h, autocatalyze the reaction for 2h, then heat up to 100°C and carry out the aging reaction for 2h;

[0071] 2) Add 20g (concentration is 50wt%) potassium hydroxide aqueous solution to step 1) system, vacuum dehydration at 110 ℃ for 2h, then add remaining epoxy olefin 776g (propylene oxide and ethylene oxide) according to flow rate 600g / h The mass ratio of alkane is 8:2), continue to react for 2h, then raise the temperature to 120°C for another 1h;

[0072] 3) At this time, 35 g of phosphoric acid aqueous solution with a concentration of 50 wt % w...

Embodiment 3

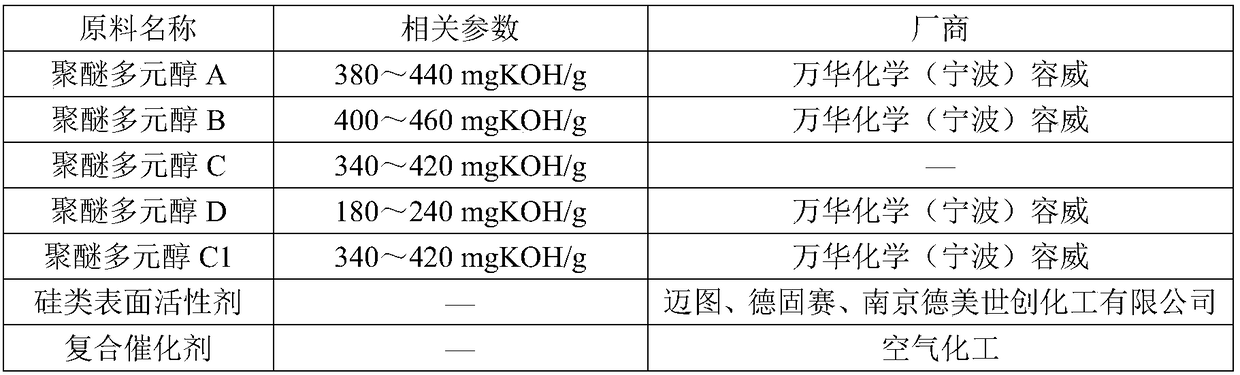

[0074] A low-density and low-conductivity HFC-134a system polyurethane rigid foam, raw material composition:

[0075] The mass ratio of combined polyether to foaming agent and polyisocyanate is 100:15:150, specifically:

[0076] The composition of the combined polyether is as follows: 91.4 parts of polyether composition, 3 parts of surfactant, 3.4 parts of composite catalyst, and 2.2 parts of distilled water;

[0077] Foaming agent: 11 parts of CP, 4 parts of HFC-134a;

[0078] Polyisocyanate: polymerized MDI Wanhua PM-200 150 parts.

[0079] In combination polyether:

[0080] The polyether composition is composed of 15 parts by weight of 3,4-diaminofurazol polyether polyol (prepared in Example 2): sucrose and glycerol polyether polyol (hydroxyl value is 385 mgKOH / g, functionality is 5.3) 51.4 Parts, 20 parts of sorbitol polyether polyol (hydroxyl value 432mgKOH / g, functionality 5.8), 5 parts of glycerol polyether polyol (hydroxyl value 192mgKOH / g, functionality 2.3);

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com