Anaerobic reactor and organic printing-dyeing wastewater treatment system comprising same

An anaerobic reactor and treatment system technology, applied in the field of organic printing and dyeing wastewater treatment systems, can solve the problems of low decolorization efficiency, large amount of sludge carried out, poor treatment effect, etc., achieve good treatment effect, low input cost, The effect of improving processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

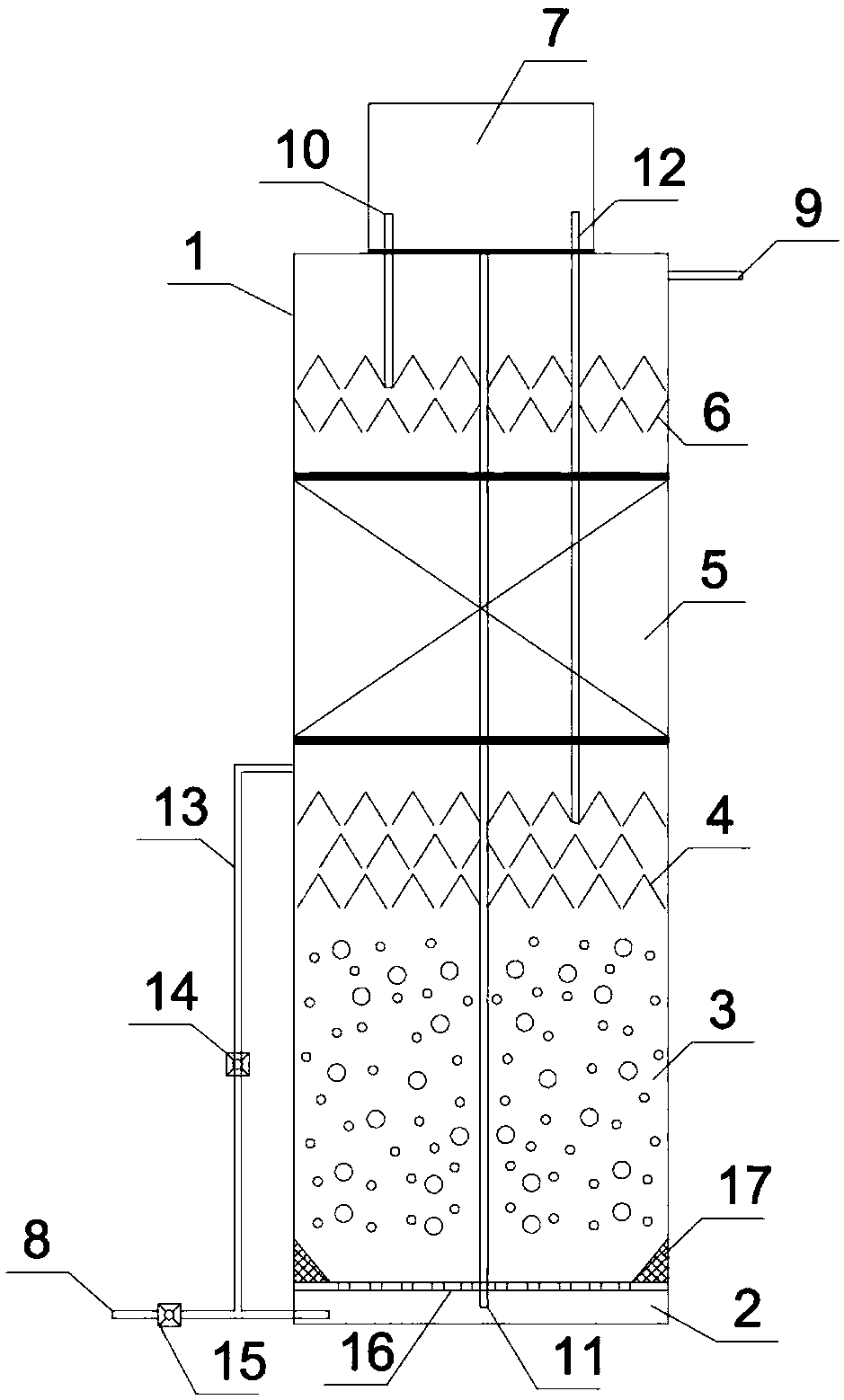

[0035] Embodiment 1: as figure 1 As shown, an anaerobic reactor includes a tower body 1, and the inside of the tower body 1 is sequentially provided with a water distribution area 2, a high-load anaerobic treatment area 3, a first-stage three-phase separation area, an anaerobic biological Membrane treatment zone 5, secondary three-phase separation zone and gas-water separation zone 7.

[0036] The water distribution area 2 is arranged at the bottom of the tower body 1 and includes a water inlet pipe 8 , a water inlet pump 15 and a water distributor 16 . The water inlet pipe 8 is connected to the water inlet at the bottom of the tower body 1; the water inlet pump 15 is arranged on the water inlet pipe 8; the water distributor 16 is arranged on the upper part of the water distribution area 2; The water dispenser 16 is a flat plate with uniform hole distribution, and the diameter of the circular hole is 10-50mm; the connection part between the water dispenser 16 and the tower bo...

Embodiment 2

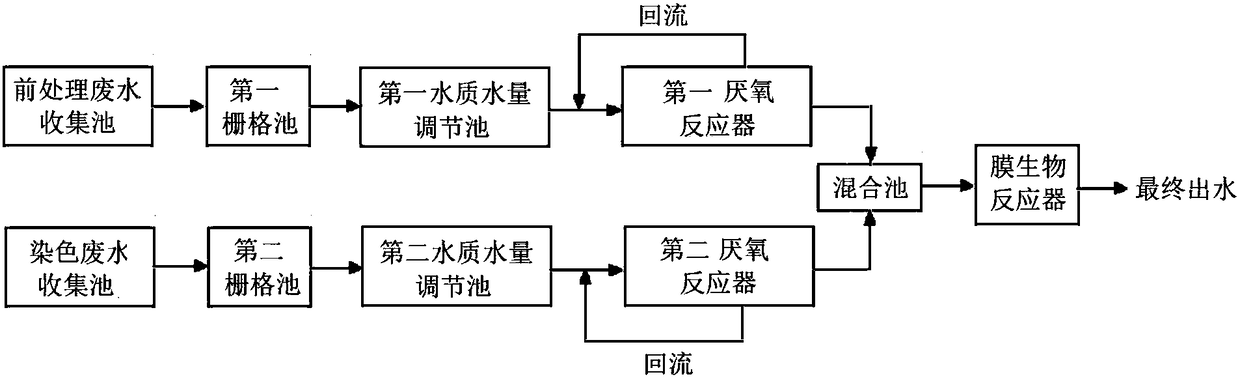

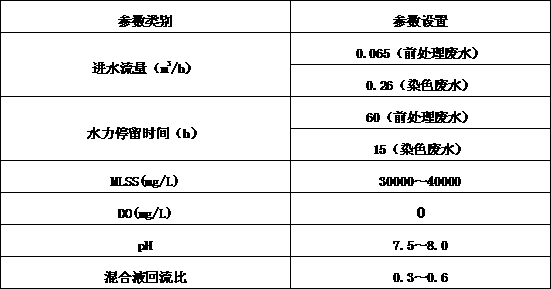

[0042] Embodiment 2: as figure 2 As shown, a high-concentration organic printing and dyeing wastewater treatment system includes a pretreatment wastewater treatment system, a dyeing wastewater treatment system and a membrane bioreactor; the pretreatment wastewater treatment system and the dyeing wastewater treatment system are respectively connected with the membrane The bioreactor is connected; the pre-treatment wastewater treatment system includes a pre-treatment wastewater collection tank, the first grid tank, the first water quality and quantity adjustment tank and the first anaerobic reactor connected in sequence; the dyeing wastewater treatment system includes sequentially The connected dyeing wastewater collection pond, the second grid pond, the second water quality and quantity regulating pond and the second anaerobic reactor;

[0043] The first anaerobic reactor and the second anaerobic reactor are respectively connected with a mixing tank, and the mixing tank is con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com