Efficient anaerobic granular sludge bed membrane bioreactor capable of self-supplying energy and operation method

An anaerobic granular sludge and membrane bioreactor technology, applied in chemical instruments and methods, anaerobic digestion treatment, biological water/sewage treatment, etc., can solve the problems of high energy consumption and large sludge production in sewage treatment, etc. Achieve the effects of slowing membrane fouling, high biomass, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

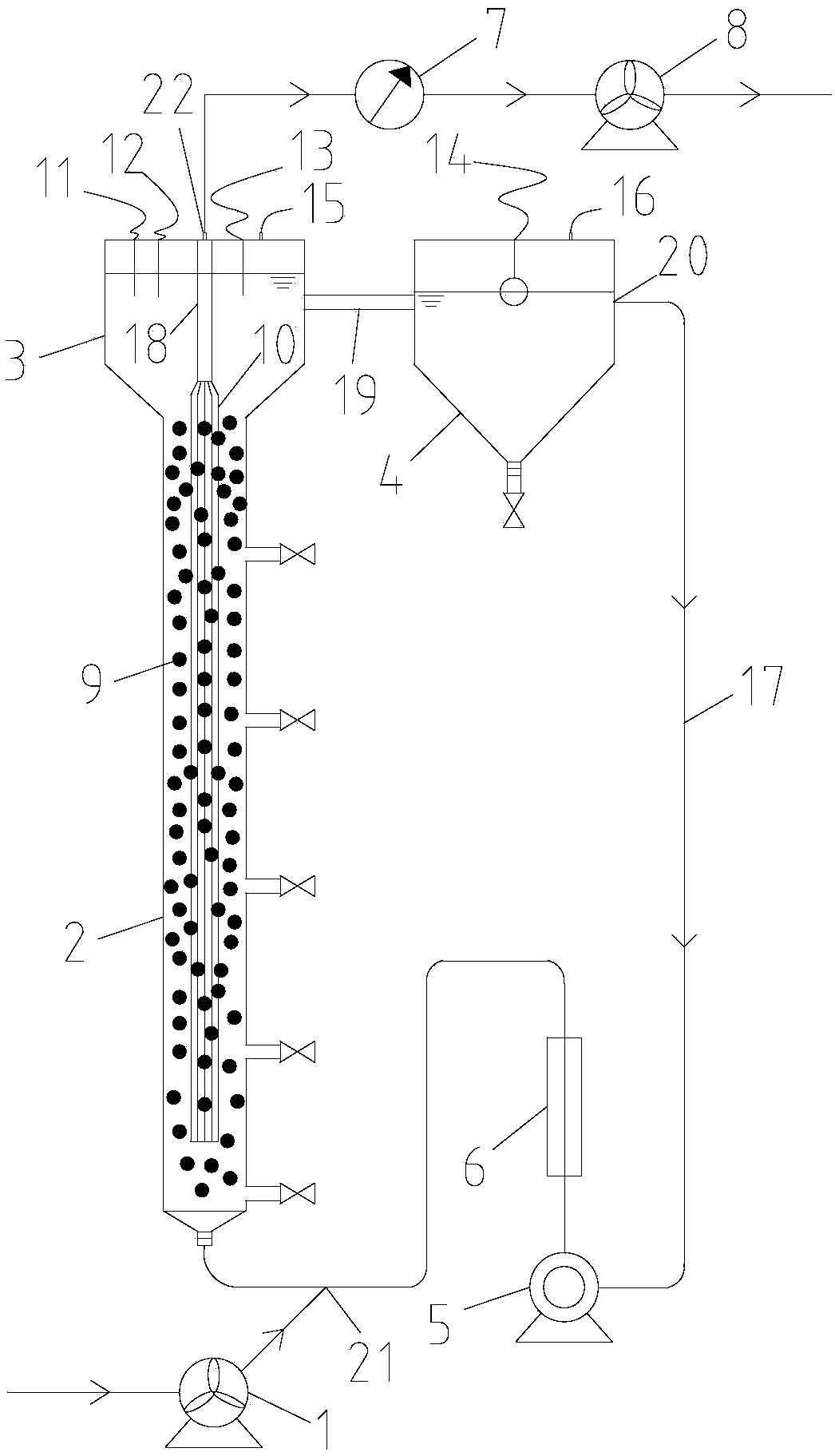

[0017] The following will be described in detail in conjunction with the accompanying drawings and embodiments, so as to further understand the present invention.

[0018] The present invention is an anaerobic granular sludge bed membrane bioreactor, comprising an influent peristaltic pump (1), a main reaction column (2), a first settling chamber (3), a second settling chamber (4), a circulating magnetic pump ( 5), rotameter (6), pressure sensor (7), effluent peristaltic pump (8), anaerobic granular sludge (9), hollow fiber membrane (10), pH electrode (11), ORP electrode (12) , DO electrode (13), liquid level controller (14), first gas collection port (15), second gas collection port (16), circulation pipeline (17).

[0019] The main reaction column (2) is a plexiglass column with a diameter of 120mm and a height of 1.2m, and five evenly arranged sampling ports are arranged on the outside of it with a spacing of 240mm. The hollow fiber membrane (10) and the anaerobic granular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com