Construction method of steel-clad concrete building piece

A construction method and concrete technology, applied to building components, buildings, manufacturing tools, etc., can solve the problems that are not conducive to the control of steel-clad beam section dimension accuracy, dust control, etc., to achieve easy control, protection of external corners, material Effects from a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

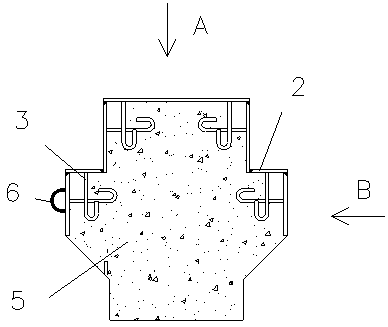

[0033] see figure 1 As shown, the steel-clad beam of the prefabricated steel-clad concrete building part is illustrated by taking the flower basket beam as an example: for the cross-sectional shape of the flower basket beam, see figure 2 , including two ends and a middle section, one end and the middle section are connected through a right-angle transition, and the other end and the middle section are transitioned through a bevel, and the cladding steel structure 2 is located on the surface of the right-angle end and the middle section. Adopt the form of inverted welded prefabricated concrete flower basket beam covered with steel formwork, cooperate with the formwork support system 1 of the part not covered with steel, so that the surface of the precast concrete flower basket beam is poured upside down and formed by one-time pouring of steel, the specific steps are as follows:

[0034] Step 1: Upside-down welding of the upper surface and sides of the precast concrete flower b...

Embodiment 2

[0046] Prefabricated steel-clad concrete building parts and steel-clad beams are explained by taking the clad concrete cover slab as an example:

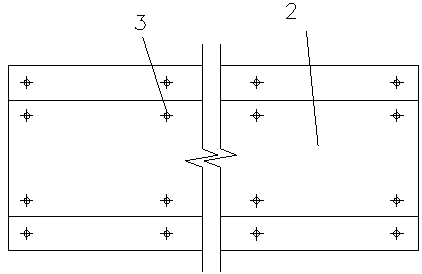

[0047] see Figure 5 As shown, the surface steel-clad structure 2 welded upside down is used as the finalized formwork for pouring the precast concrete cover, and the anchor bars 3 are preset inside the steel-clad structure, so that the precast concrete cover can be poured at one time. The specific steps are as follows:

[0048] Step 1: use the closed steel plate on the surface of the prefabricated concrete cover plate as the concrete pouring bottom form, and weld the anchor bar 3 on the surface steel plate;

[0049] Step 2: Open round holes 8 at the four corners of the steel plate on the surface;

[0050] Step 3: welding the angle steel frame 22 upside down on the surface steel plate 21;

[0051] Step 4: Preset the anchor bar 3 inside the angle steel frame around;

[0052] Step 5: Weld the surrounding angle steel frame and the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Vertical spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com