Perforated positive plate of lithium ion battery, and preparation method thereof

A technology for lithium ion batteries and cathode sheets, which is applied in electrode manufacturing, battery electrodes, electrode current collector coatings, etc. High rate capability, areal density and compaction, effect of increasing wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

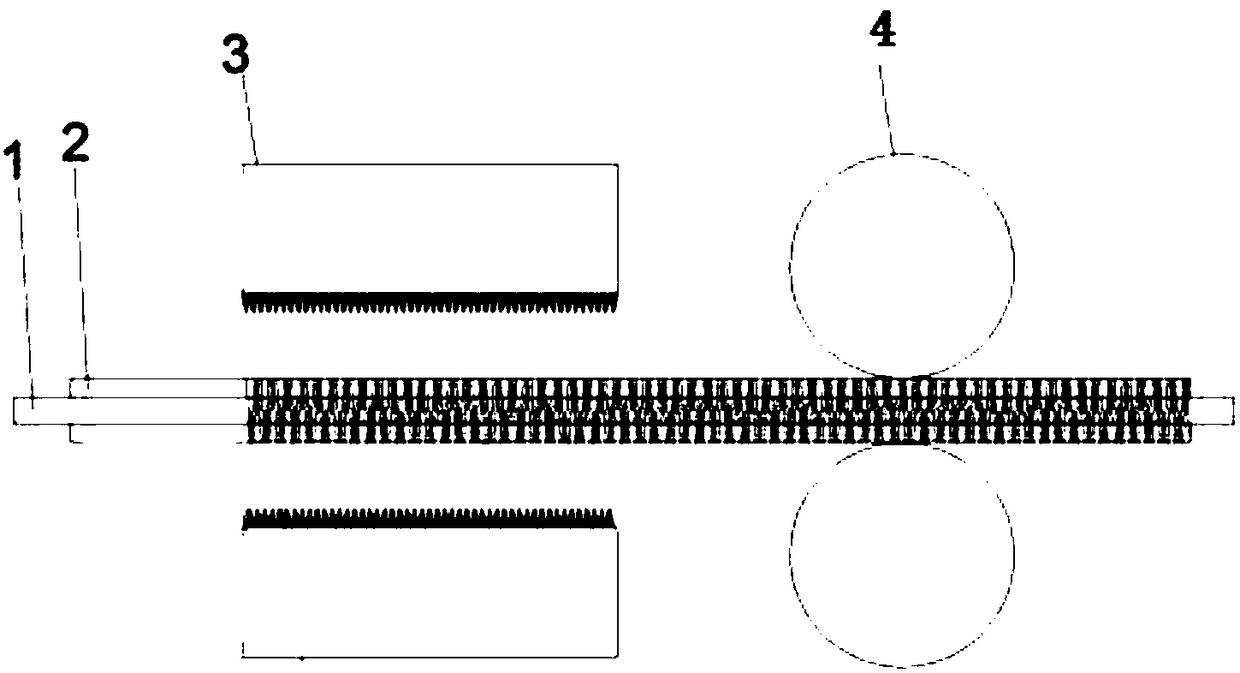

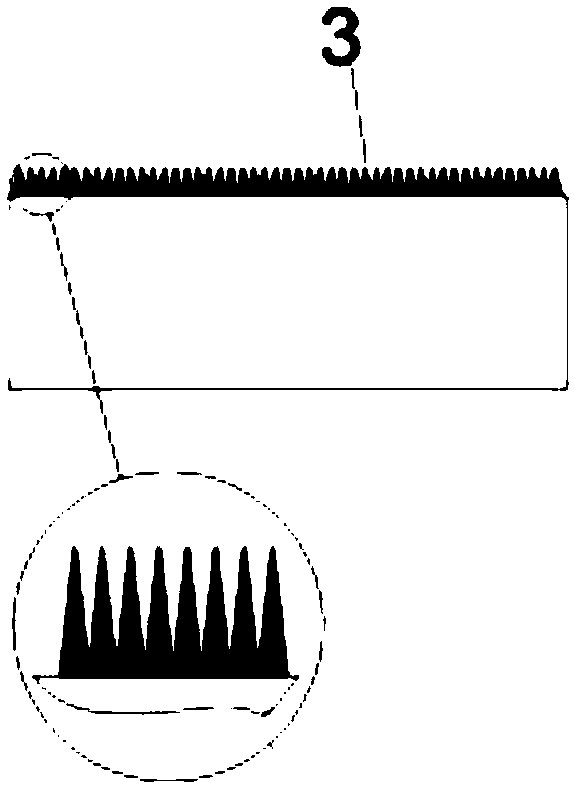

[0029] Such as Figure 1-3 Shown, the preparation process of the perforated positive electrode sheet of lithium-ion battery comprises the following steps:

[0030] 1) Preparation of lithium iron oxide layer slurry Weigh lithium iron oxide Li according to the ratio 5 FeO 4 , binder PAA, dispersant PVP, after uniform mixing to prepare lithium iron oxide layer slurry,

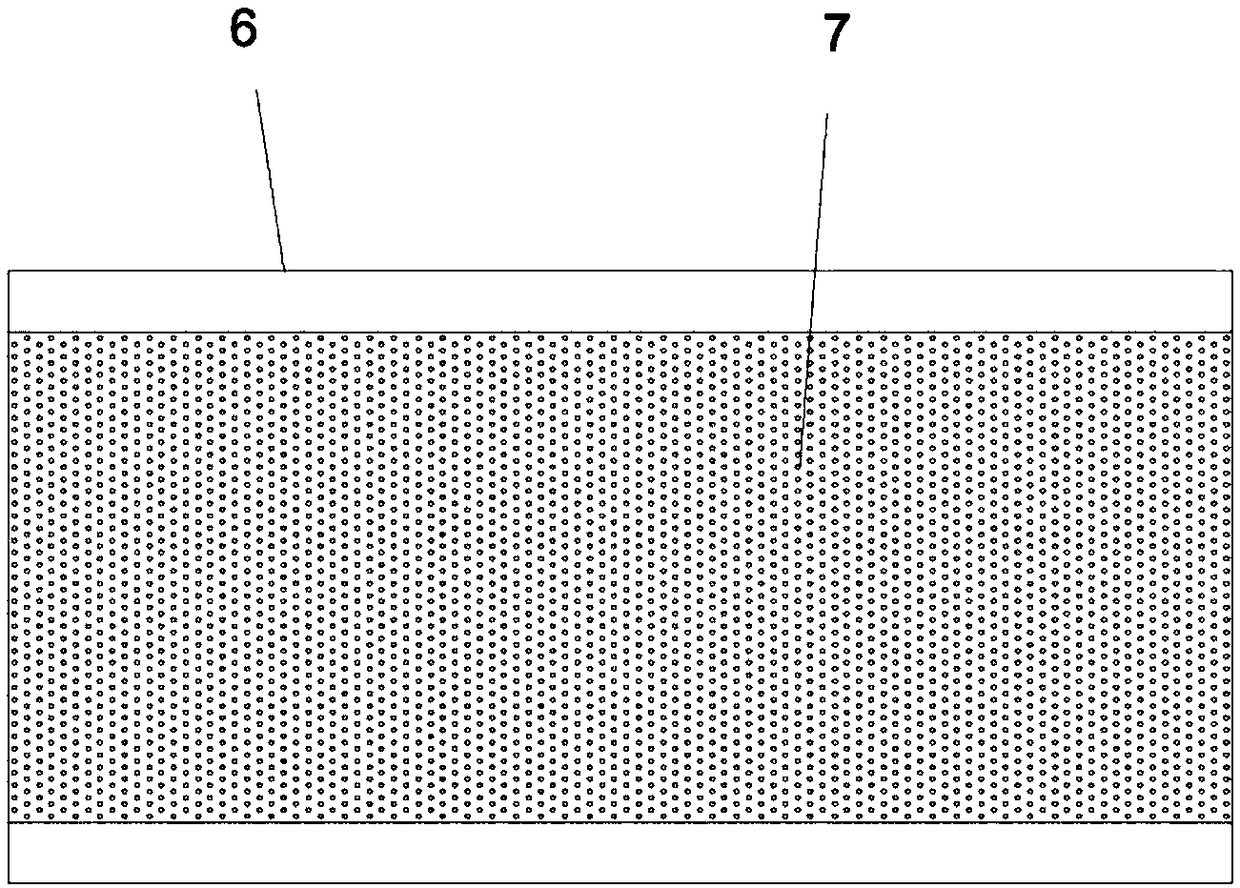

[0031] 2) Coating the lithium iron oxide layer slurry The prepared lithium iron oxide layer slurry is coated on the upper and lower surfaces of 2 μm aluminum foil to obtain a 6 μm current collector; the thickness of the lithium iron oxide layer is 2 μm;

[0032] 3) Preparation of active material layer Weigh 95 parts of NCM811; 1 part of CNT; 2 Evenly coated on the surface of the current collector;

[0033] 4) Pressing of the positive electrode sheet The current collector coated with the active material layer is rolled to obtain a positive electrode sheet with a compacted density of 3.4-3.5;

[0034] 5) Drill...

Embodiment 2

[0036] The preparation process of the perforated positive electrode sheet of lithium ion battery comprises the following steps:

[0037] 1) Preparation of lithium iron oxide layer slurry Weigh lithium iron oxide Li according to the ratio 5 FeO 4 , binder PAA, dispersant PVP, after uniform mixing to prepare lithium iron oxide layer slurry,

[0038] 2) Coating the lithium iron oxide layer slurry The prepared lithium iron oxide layer slurry is coated on the upper and lower surfaces of 40 μm aluminum foil to obtain a 50 μm current collector; the thickness of the lithium iron oxide layer is 5 μm;

[0039] 3) Preparation of active material layer Weigh 98 parts of NCM811; 0.5 part of CNT; 0.5 part of PCDF5138 by weight, and mix them uniformly to make active material layer slurry. 2 Evenly coated on the surface of the current collector;

[0040] 4) Pressing of the positive electrode sheet The current collector coated with the active material layer is rolled to obtain a positive ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com