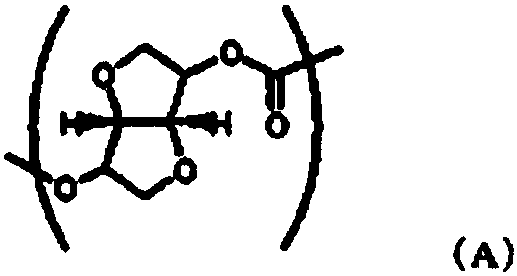

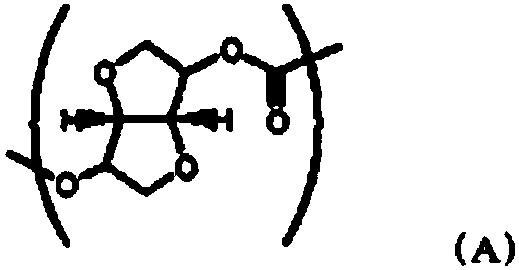

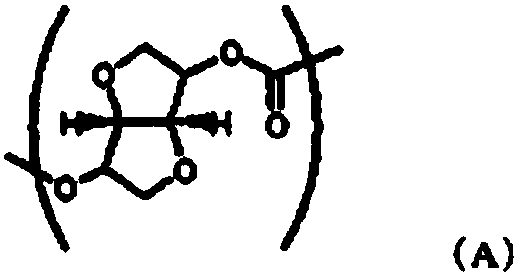

Retardation film process for producing same and display device using same

A technology of retardation film and manufacturing method, applied in chemical instruments and methods, instruments, layered products, etc., can solve the problems of intractability, high birefringence performance, low photoelastic constant, etc., to achieve high performance, bending Excellent properties and processability, low photoelastic constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0156] 441 parts of isosorbide (hereinafter abbreviated as ISS), 66 parts of 1,9-nonanediol (hereinafter abbreviated as ND), 750 parts of diphenyl carbonate (hereinafter abbreviated as DPC) and tetramethylammonium hydroxide as a catalyst 0.8× 10 -2 parts and NaOH 0.6×10 -4 The parts were melted by heating to 180°C under a nitrogen atmosphere. Then, the degree of reduced pressure was adjusted to 13.4 kPa over 30 minutes. Then, the temperature was raised to 240° C. at a rate of 60° C. / hr, and the temperature was maintained for 10 minutes, and then the degree of reduced pressure was reduced to 133 Pa or less over 1 hour. The reaction was carried out under stirring for a total of 6 hours, discharged from the bottom of the reaction tank under nitrogen pressure, and cut with a pelletizer while cooling in a water tank to obtain copolymerized polycarbonate resin pellets as resin A.

manufacture example 2

[0158] Using 366 parts of ISS, 3,9-bis(2-hydroxy-1,1-dimethylethyl)-2,4,8,10-tetraoxaspiro(5.5)undecane (hereinafter abbreviated as SPG) 219 parts, 33 parts of ND, except that, the same operation as the resin production example 1 was performed to obtain a copolymerized polycarbonate resin.

manufacture example 3

[0160] Except having used 366 parts of ISS, 125 parts of SPG, and 83 parts of ND, the same operation as resin manufacture example 1 was performed, and the copolymerized polycarbonate resin was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| photoelasticity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com