Composite gas-sensitive material used for detecting formaldehyde gas and preparation method thereof

A technology of gas-sensitive materials and formaldehyde gas, which is applied in the direction of material excitation analysis, fluorescence/phosphorescence, etc., can solve the problems of high working temperature, poor selectivity and stability, and achieve low working temperature, good selectivity and high sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

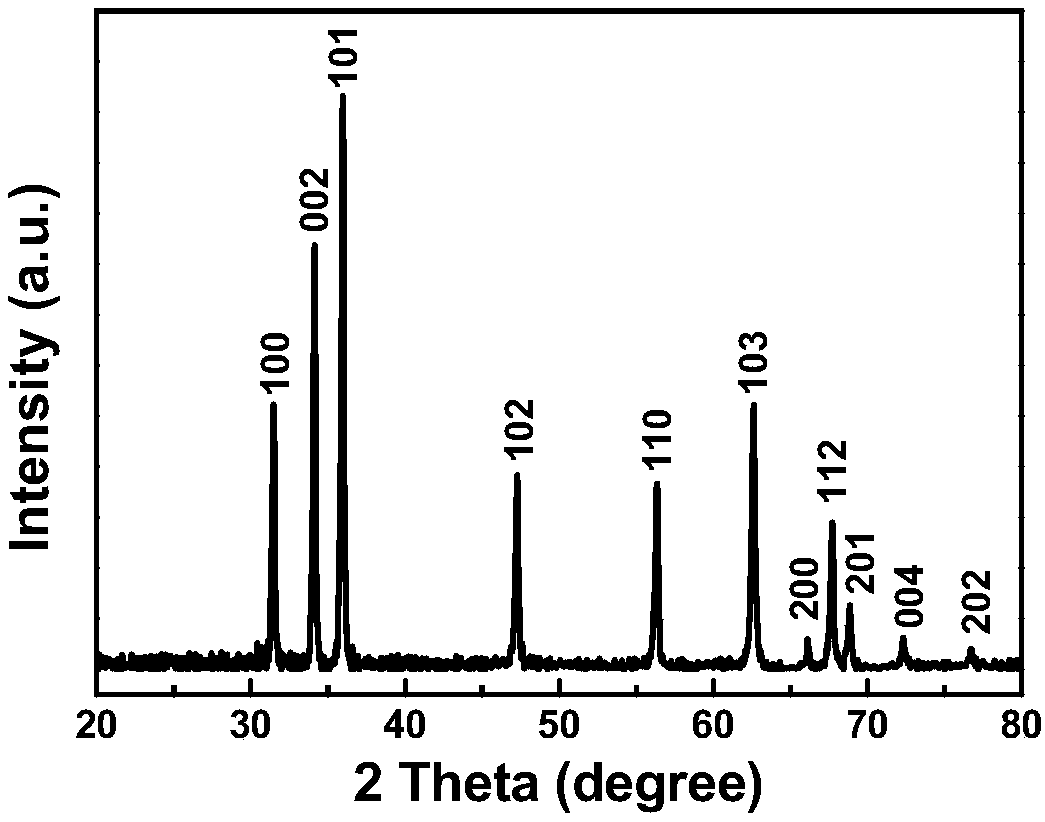

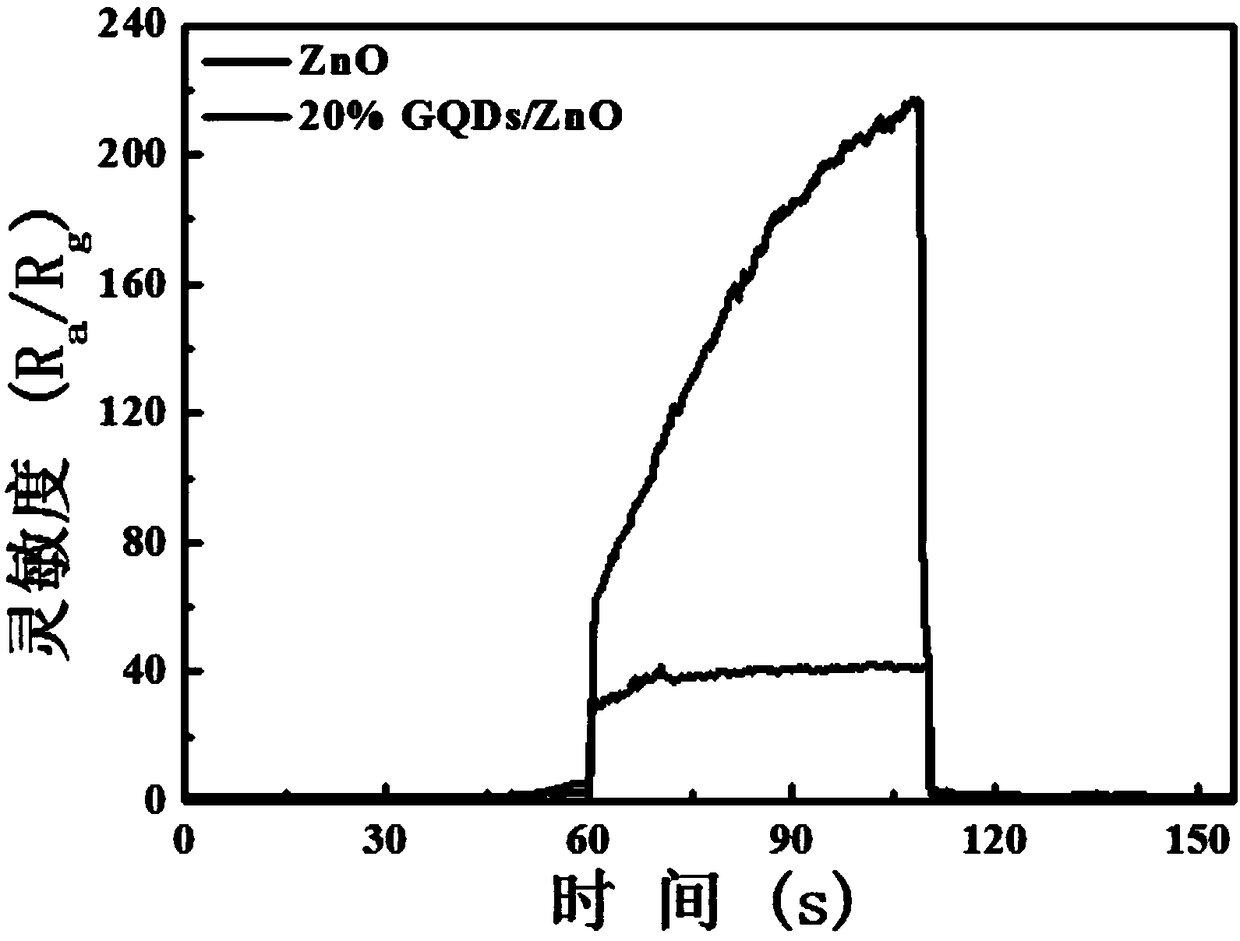

[0057] The composite gas-sensing material provided by the present invention is metal oxide and graphene quantum dot material calculated by mass percentage, that is, the graphene quantum dot material accounts for 5%, 10%, 20%, and 30% of the total mass percentage of the composite;

[0058] The metal oxide is zinc oxide;

[0059] The graphene quantum dots are nitrogen-doped graphene quantum dots;

[0060] The zinc oxide is a regular nanosheet structure with a size of 4-10 μm and a thickness of 50-100 nm;

[0061] The graphene quantum dot material is a circular nanosheet structure with a size of 5-20nm and a thickness of 0.6-5nm.

[0062] The preparation method of the above-mentioned composite gas-sensitive material specifically includes the following steps:

[0063] 1. Preparation of ZnO nanosheets by hydrothermal method

[0064] a. Dissolve 4mmol of zinc chloride in 20ml of deionized water and stir for 10min to uniformly disperse zinc chloride in the solution; dissolve 4mmol...

Embodiment 2

[0076] Embodiment 2: This embodiment is basically the same as Embodiment 1, except that in step 3, graphene quantum dots account for 5% of the total mass of the composite.

Embodiment 3

[0077] Embodiment 3: This embodiment is basically the same as Example 1, except that in step 3, graphene quantum dots account for 10% of the total mass of the composite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com