Fire coal coupling biomass, garbage and sludge gasification combustion combined heat and power generation device and process

A technology of sludge gasification and cogeneration of heat and power, which is applied in the direction of steam engine devices, machines/engines, mechanical equipment, etc., can solve the problem of the inability to realize long-term stable operation of large-scale industrialization, the small room for adjustment of the gasifier system, and the inability to adapt to various raw materials To achieve the effect of improving gasification efficiency and gas production, fully utilizing calorific value and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]Below in conjunction with embodiment, the present invention is described in further detail.

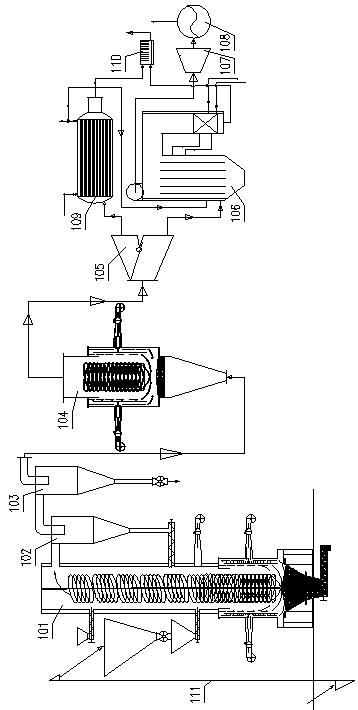

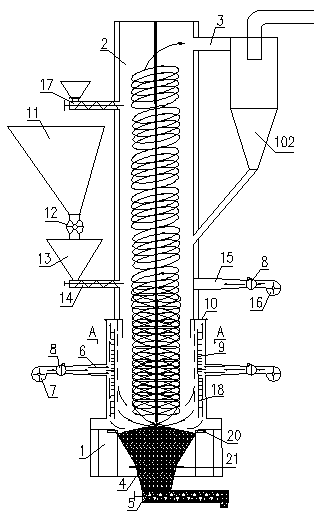

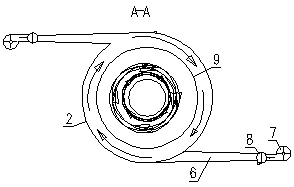

[0025] Such as Figure 1 to Figure 5 As shown, the coal-fired coupled biomass, garbage, sludge gasification combustion cogeneration device includes a cyclone fluidized bed gasifier 101, a cyclone separator 102, a cyclone dust collector 103 and a cyclone fluidized bed gas combustion Machine 104, thermal power boiler 106, steam turbine 107 and generator 108 connected in sequence, cyclone type fluidized bed gasification furnace 101 includes support 1, furnace body 2, exhaust pipe 3 connected to the upper part of the furnace body, connected to the furnace body The conical discharge hopper 4 at the bottom and the exhaust pipe 3 are connected to the cyclone separator 102, and the discharge port of the cyclone separator 102 is connected to the inside of the body of furnace 1; the outlet of the conical discharge hopper 4 is connected to the spiral ash machine 5. The conical discharge h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com