Cylinder material for electric executer and preparation method thereof

A technology for electric actuators and cylinders, which is applied in the field of cylinder materials for electric actuators and its preparation, can solve the problems of shortening the service life of electric actuator cylinders, affecting the sensitivity of electric actuators, corrosion and peeling of electric cylinders, etc., and achieves transmission efficiency and Executes effects with high accuracy, low coefficient of thermal expansion, and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

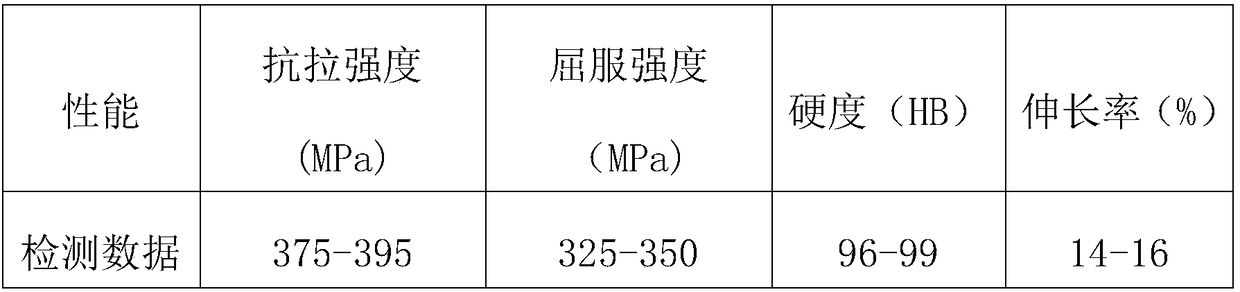

Examples

Embodiment 1

[0018] A cylinder for an electric actuator according to the present invention, its distribution ratio of each component in terms of weight percentage is: Fe: 0.57%, Cu: 1.65%, Mg: 0.85%, Mn: 0.18%, Ni: 1.55% , Zn: 1.9%, B 2 o 3 : 0.55%, SiO 2 : 1.85%, TiC: 2.0%, Pt: 0.6%, Ti: 0.45%, Pb: 0.45%, and the rest are Al.

[0019] A method for preparing a cylinder for an electric actuator, comprising the following steps,

[0020] (1) Embryo making: Mix the prepared raw materials of each component evenly and add them to the melting furnace, heat up to melt, and after the raw materials are completely melted, adjust the internal temperature of the melting furnace to 760°C for refining treatment, and then Adjust the internal temperature of the melting furnace to 710°C, carry out refining treatment, and finally cool down slowly for 6 hours to obtain a cylindrical aluminum alloy billet of Φ300mm;

[0021] (2) Billet pretreatment: first clean the aluminum alloy billet, remove surface oil...

Embodiment 2

[0027] A cylinder for an electric actuator according to the present invention, the distribution ratio of each component in terms of weight percentage is: Fe: 0.55%, Cu: 1.7%, Mg: 0.8%, Mn: 0.19%, Ni: 1.45% , Zn: 2.0%, B 2 o 3 : 0.5%, SiO 2 : 2.0%, TiC: 2.2%, Pt: 0.65%, Ti: 0.5%, Pb: 0.5%, and the rest are Al.

[0028] A method for preparing a cylinder for an electric actuator, comprising the following steps:

[0029] (1) Embryo making: Mix the prepared raw materials of each component evenly and add them to the melting furnace, heat up to melt, and after the raw materials are completely melted, adjust the internal temperature of the melting furnace to 770°C for refining treatment, and then Adjust the internal temperature of the melting furnace to 720°C, carry out refining treatment, and finally cool down slowly for 7 hours to obtain a cylindrical aluminum alloy billet of Φ550mm;

[0030] (2) Billet pretreatment: first clean the aluminum alloy billet, remove surface oil and ...

Embodiment 3

[0036] A cylinder for an electric actuator according to the present invention, the distribution ratio of each component in terms of weight percentage is: Fe: 0.59%, Cu: 1.9%, Mg: 0.75%, Mn: 0.22%, Ni: 1.58% , Zn: 2.1%, B 2 o 3 : 0.6%, SiO2 : 2.1%, TiC: 2.3%, Pt: 0.72%, Ti: 0.58%, Pb: 0.62%, and the rest are Al.

[0037] A method for preparing a cylinder for an electric actuator, comprising the following steps:

[0038] (1) Embryo making: Mix the prepared raw materials of each component evenly and put them into the melting furnace, heat up to melt, and after the raw materials are completely melted, adjust the internal temperature of the melting furnace to 780°C for refining treatment, and then Adjust the internal temperature of the melting furnace to 730°C, carry out refining treatment, and finally cool down slowly for 8 hours to obtain a cylindrical aluminum alloy billet of Φ750mm;

[0039] (2) Billet pretreatment: first clean the aluminum alloy billet, remove surface oil a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com