Rotary Spray Quenching Technology of High Chromium Wear-resistant Iron Castings

A technology of wear-resistant cast iron and rotating spray, which is applied in the field of casting quenching, can solve the problems that the surface wear resistance of high-chromium castings cannot be guaranteed, the uniformity of quenching temperature of workpieces cannot be guaranteed, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

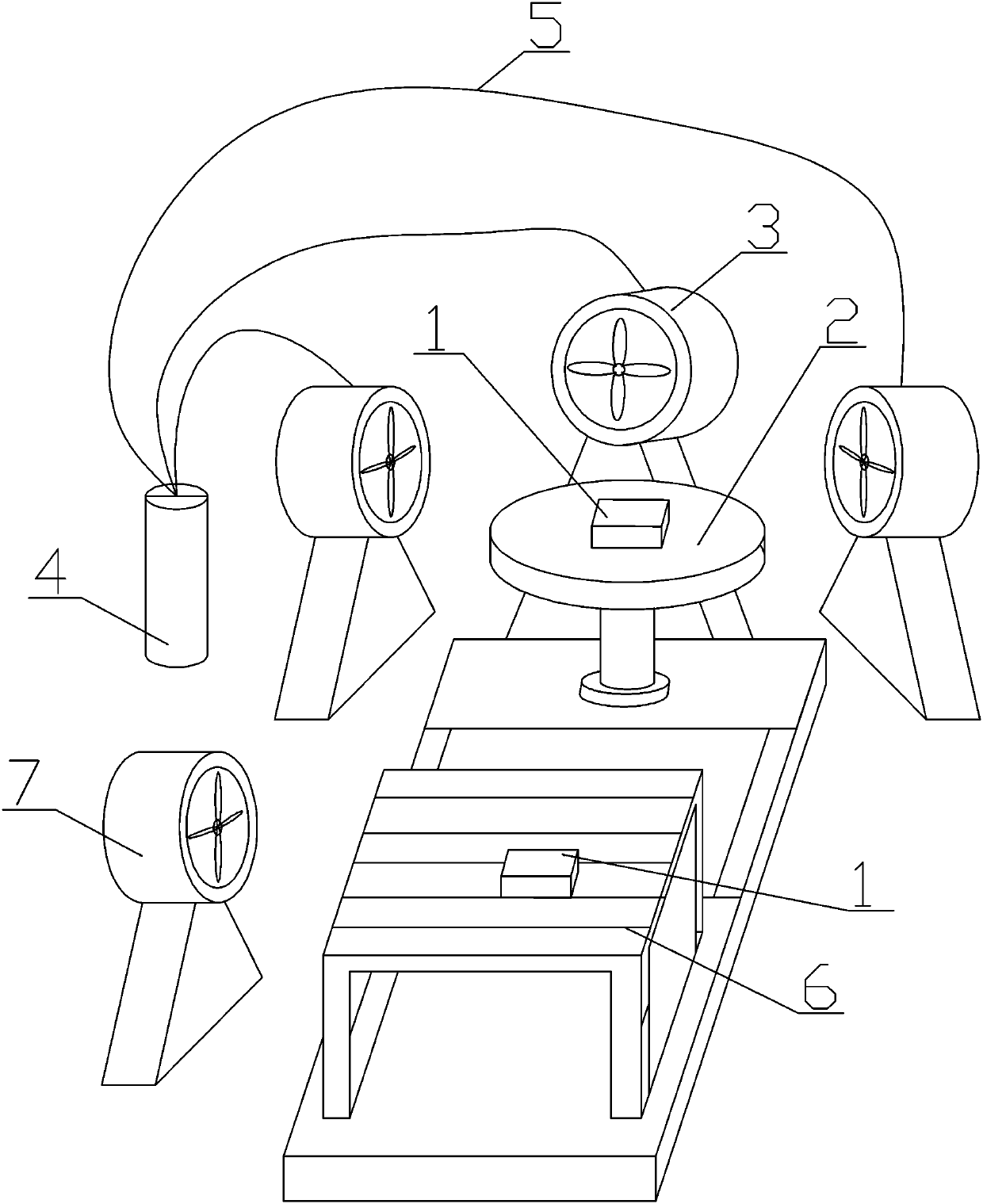

Image

Examples

Embodiment 1

[0036] A rotary spray quenching process for high chromium wear-resistant iron castings, which includes the following steps:

[0037] Step 1: Place the cast workpiece 1 to be quenched in a high-temperature furnace to heat up to a temperature of 1000°C and keep it warm for 3.5 hours;

[0038] The second step: placing the high-temperature casting workpiece 1 in the first step on the rotary table 2;

[0039] The third step: start the rotary table 2, and drive the casting workpiece 1 to rotate at a high speed through the rotary table 2;

[0040] The fourth step: start the spray device 3 located on the side of the rotary table 2; and supply water to the spray device 3 through the water supply device 4 and the water supply pipe 5;

[0041] Step 5: Spray the atomized water to the surface of the rotating casting workpiece through the spray device 3, and perform quenching treatment on the casting workpiece, wherein the air volume of the fan of the spray device 3 is controlled at 31500 ...

Embodiment 2

[0046] A rotary spray quenching process for high chromium wear-resistant iron castings, which includes the following steps:

[0047] Step 1: Place the cast workpiece 1 to be quenched in a high-temperature furnace to heat up to 1050°C, and keep it warm for 3.5 hours;

[0048] The second step: placing the high-temperature casting workpiece 1 in the first step on the rotary table 2;

[0049] The third step: start the rotary table 2, and drive the casting workpiece 1 to rotate at a high speed through the rotary table 2;

[0050] The fourth step: start the spray device 3 located on the side of the rotary table 2; and supply water to the spray device 3 through the water supply device 4 and the water supply pipe 5;

[0051] Step 5: Spray the atomized water to the surface of the rotating casting workpiece through the spray device 3, and perform quenching treatment on the casting workpiece, wherein the air volume of the fan of the spray device 3 is controlled at 31500 m³ / h and lasts f...

Embodiment 3

[0055] A rotary spray quenching process for high chromium wear-resistant iron castings, which includes the following steps:

[0056] Step 1: Place the cast workpiece 1 to be quenched in a high-temperature furnace to heat up to a temperature of 1050°C and keep it warm for 4.5 hours;

[0057] The second step: placing the high-temperature casting workpiece 1 in the first step on the rotary table 2;

[0058] The third step: start the rotary table 2, and drive the casting workpiece 1 to rotate at a high speed through the rotary table 2;

[0059] The fourth step: start the spray device 3 located on the side of the rotary table 2; and supply water to the spray device 3 through the water supply device 4 and the water supply pipe 5;

[0060] Step 5: Spray the atomized water to the surface of the rotating cast workpiece through the spray device 3, and perform quenching treatment on the cast workpiece. The wind pressure is controlled at 800Mpa, so that the temperature of the cast workp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com