Two-dimensional material modified glass fiber composite material and manufacturing method thereof

A glass fiber and two-dimensional material technology, which is applied in the field of two-dimensional material modified glass fiber composite materials and its production, can solve the problems of not making good use of two-dimensional materials, and the improvement effect is not very ideal, and achieves good practicability. , Increase the interaction area and interface bonding force, the effect of uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for manufacturing a two-dimensional material modified glass fiber composite material, comprising the following steps:

[0028] S1, mix 3.4-4.2Kg of silane coupling agent with 135-170Kg of deionized water, stir for 25-35 minutes, add 7.5-9.5Kg of plasticizer and Ph regulator, control Ph to 8-9, and form solution A ;

[0029] S2, mixing 25-32Kg of binder with 34-42Kg of deionized water to form solution B;

[0030] S3, mix 9-12Kg additives with 34-42Kg deionized water, stir for 40-50 minutes to form solution C;

[0031] S4, solutions A, B, C are mixed with 28-35Kg graphene aqueous solution to form solution D, stirred for 10-20 minutes; then placed in an environment of 16-24°C for 20-25 minutes;

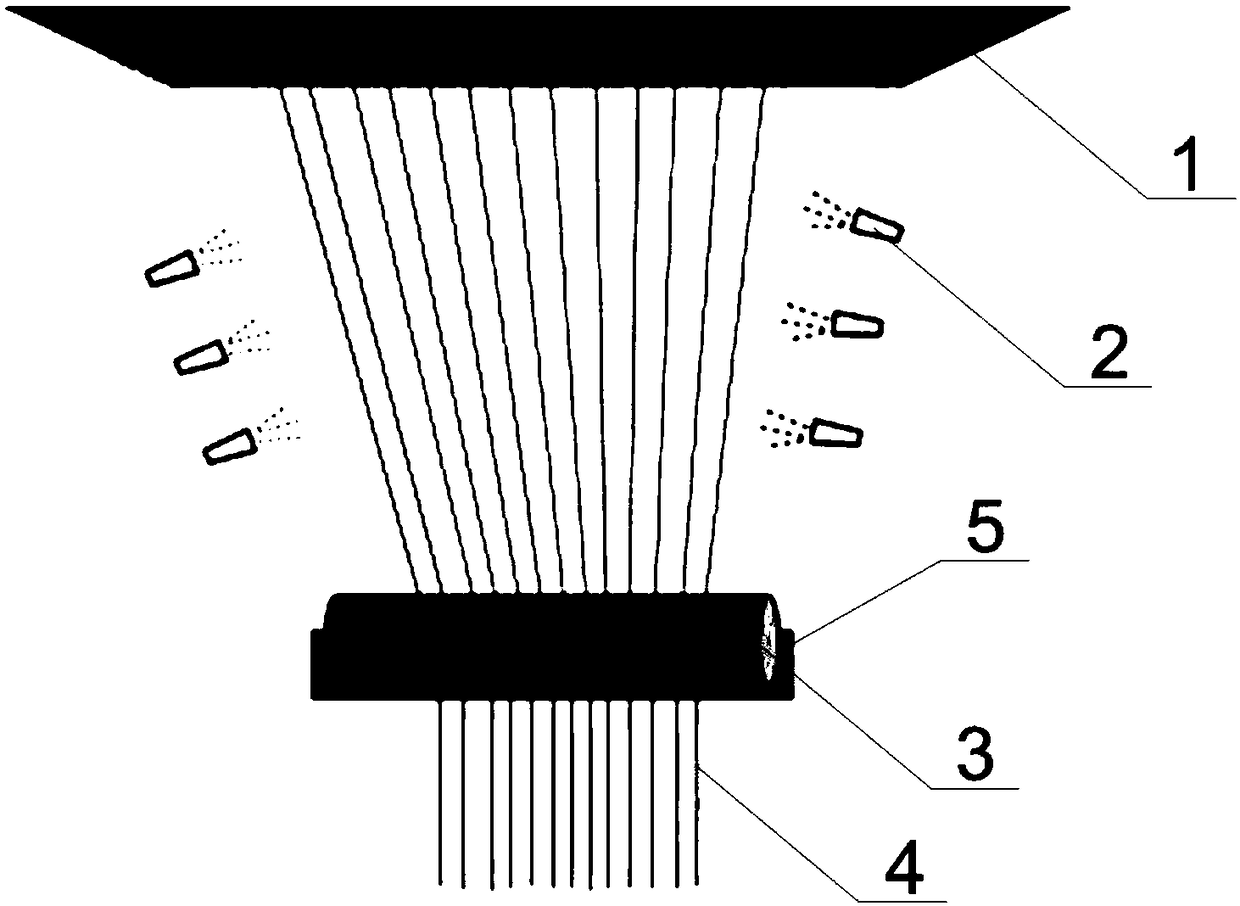

[0032] S5, put the solution D after the treatment of S4 into the container, and complete it in the online drawing process of glass fiber. After the glass fiber is heated and melted and pulled out from the bushing plate, it is not completely cooled, that is, the temperat...

Embodiment 2

[0034] A method for manufacturing a two-dimensional material modified glass fiber composite material, comprising the following steps:

[0035] S1, mix 4.2Kg of silane coupling agent with 135Kg of deionized water, stir for 25 minutes, add 7.5Kg of plasticizer and Ph regulator, control Ph to 8, and form solution A;

[0036] S2, 25Kg adhesive is mixed with 34Kg deionized water to form solution B;

[0037] S3, mix 9Kg additive with 34Kg deionized water, stir for 40 minutes to form solution C;

[0038] S4, solutions A, B, C are mixed with 28Kg graphene aqueous solution to form solution D, stirred for 10 minutes; then placed in an environment of 16°C for 20 minutes;

[0039] S5, put the solution D treated in S4 into the container, and complete it in the process of glass fiber online drawing. After the glass fiber is heated and melted and pulled out from the bushing plate, it is not completely cooled, that is, when the temperature is 100°C , to complete the impregnation with Soluti...

Embodiment 3

[0041] A method for manufacturing a two-dimensional material modified glass fiber composite material, comprising the following steps:

[0042] S1, mix 4.2Kg of silane coupling agent with 170Kg of deionized water, stir for 35 minutes, add 9.5Kg of plasticizer and Ph regulator, control Ph to 9, and form solution A;

[0043] S2, 32Kg adhesive is mixed with 42Kg deionized water to form solution B;

[0044] S3, mix 12Kg auxiliary agent with 42Kg deionized water, stir for 50 minutes to form solution C;

[0045] S4, solutions A, B, C are mixed with 35Kg graphene aqueous solution to form solution D, stirred for 20 minutes; then placed in an environment of 24°C for 25 minutes;

[0046]S5, put the solution D treated in S4 into the container, and finish it in the glass fiber online drawing process. After the glass fiber is heated and melted and pulled out from the bushing plate, it is not completely cooled, that is, when the temperature is 400 ° C. , to complete the impregnation with s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com