A rare earth-doped luminescent glass and its preparation method

A technology of luminescent glass and rare earth doping, which is applied in the field of inorganic luminescent materials, rare earth doped luminescent glass and its preparation, which can solve the problems of microcrystallization of luminescent glass, complex spectrum control, low mechanical strength, etc., and achieve mechanical Good performance, controllable spectrum and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

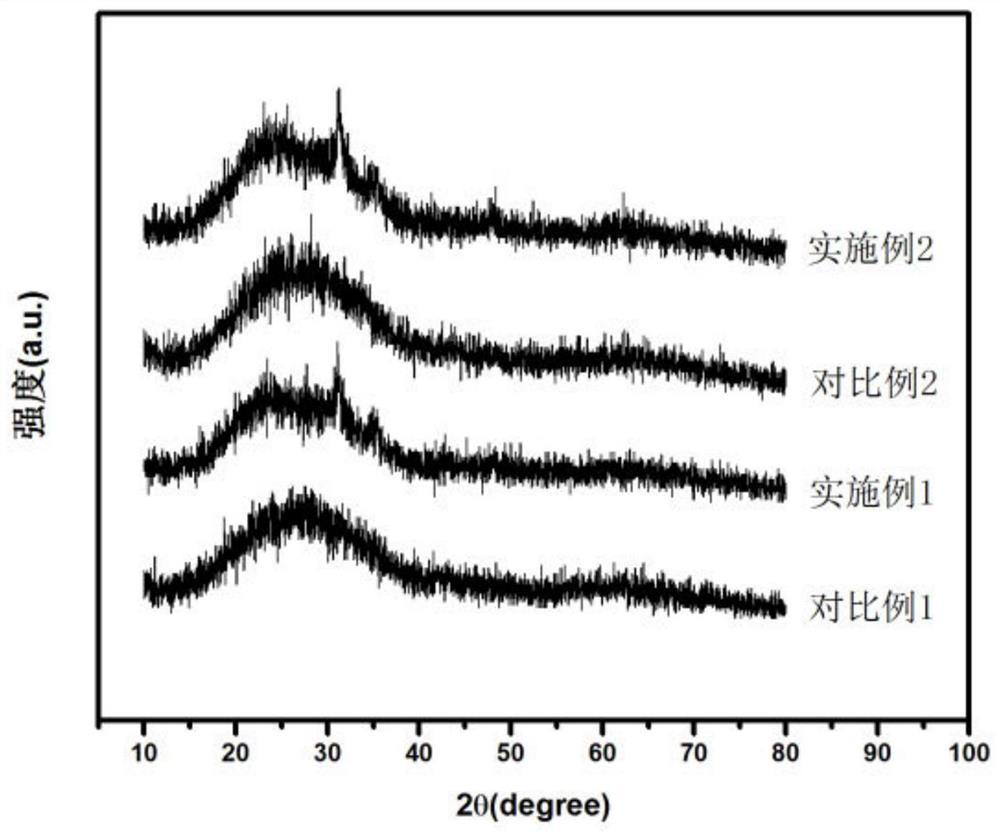

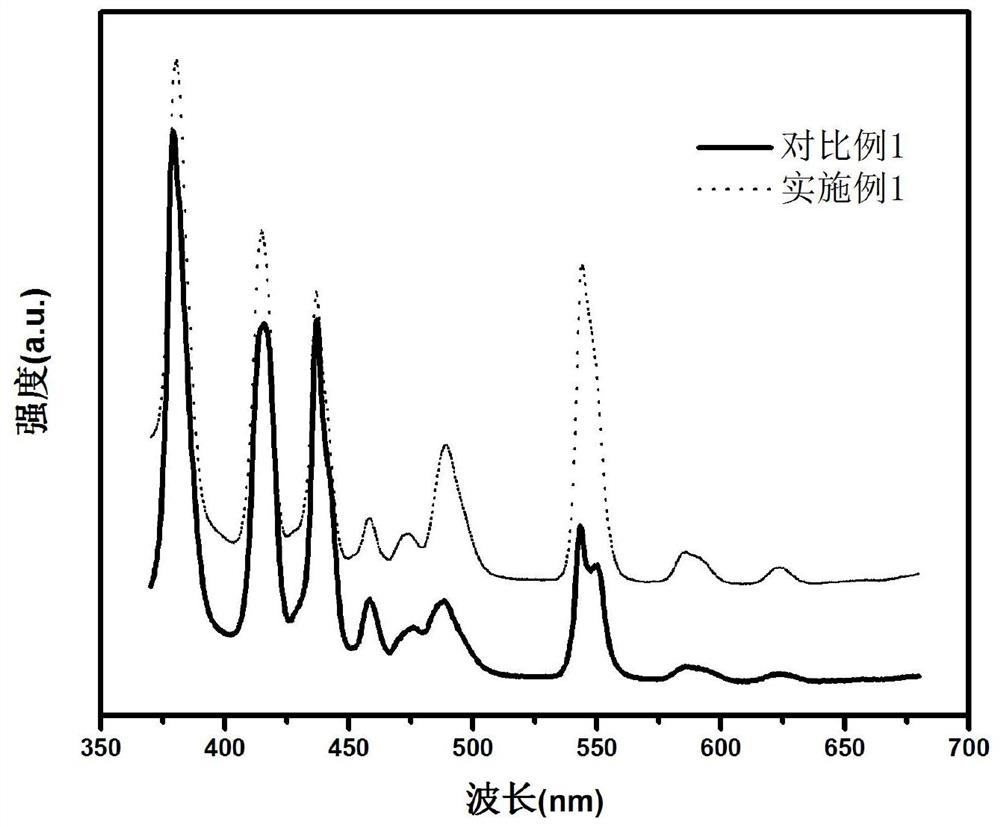

Embodiment 1

[0033] A rare earth-doped luminescent glass, comprising the following mole fractions: SiO2 : 55 copies, P 2 o 5 : 5 parts, Al 2 o 3 : 8 parts, ZnO: 12 parts, CaO: 10 parts, Na 2 O: 10 parts, Tb 4 o 7 : 0.02 parts.

[0034] The preparation method of the above-mentioned rare earth-doped luminescent glass comprises the steps of:

[0035] (1) Accurately weigh 13.8962g of silicon dioxide, 4.8370g of ammonium dihydrogen phosphate, 3.4302g of aluminum oxide, 4.1073g of zinc oxide, 4.2091g of calcium carbonate, 4.4573g of sodium carbonate, and 0.0629g of terbium oxide according to the composition of the above-mentioned luminescent glass. g, after fully grinding and mixing these raw materials to obtain a glass batch;

[0036] (2) Melting: Pour the glass batch into a corundum crucible, heat up to 1550°C at a heating rate of 5°C / min under air atmosphere, and melt at 1550°C for 1 hour to obtain molten glass; 2) The obtained molten glass is poured into a preheated stainless steel m...

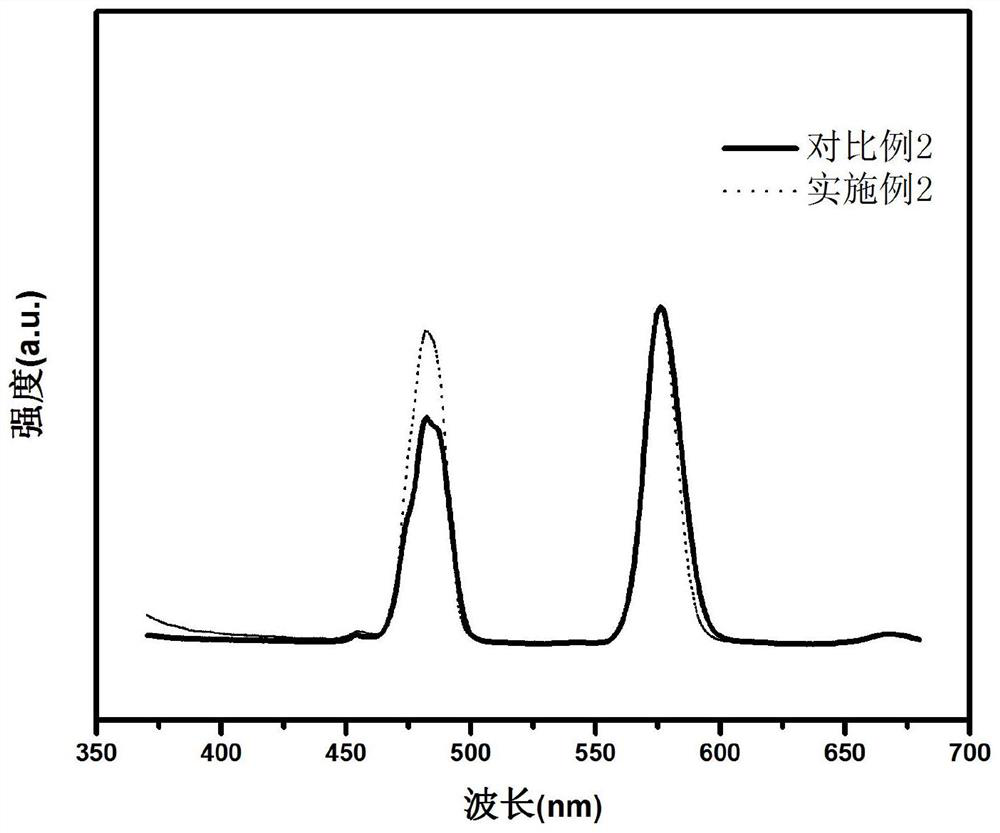

Embodiment 2

[0040] A rare earth-doped luminescent glass, comprising the following mole fractions: SiO 2 : 55 copies, P 2 o 5 : 5 parts, Al 2 o 3 : 8 parts, ZnO: 12 parts, CaO: 10 parts, Na 2 O: 10 parts, Dy 2 o 3 : 0.05 parts.

[0041] The preparation method of the above-mentioned rare earth-doped luminescent glass comprises the steps of:

[0042] (1) Accurately weigh 13.8900g of silicon dioxide, 4.8349g of ammonium dihydrogen phosphate, 3.4287g of aluminum oxide, 4.1055g of zinc oxide, 4.2073g of calcium carbonate, 4.4553g of sodium carbonate, and 0.0784g of dysprosium oxide according to the composition of the above-mentioned luminescent glass. g, after fully grinding and mixing these raw materials to obtain a glass batch;

[0043] (2) Melting: Pour the glass batch into a corundum crucible, heat up to 1550°C at a heating rate of 5°C / min under air atmosphere, and melt at 1550°C for 1 hour to obtain molten glass; 2) The obtained molten glass is poured into a preheated stainless st...

Embodiment 3

[0047] A rare earth-doped luminescent glass, comprising the following mole fractions:

[0048] SiO 2 : 55 copies, P 2 o 5 : 5 parts, Al 2 o 3 : 8 parts, ZnO: 12 parts, CaO: 10 parts, Na 2 O: 10 parts, Tb 4 o 7 : 0.02 parts, Dy 2 o 3 : 0.05 parts.

[0049] The preparation method of the above-mentioned rare earth-doped luminescent glass comprises the steps of:

[0050] (1) Accurately weigh 13.8651g of silicon dioxide, 4.8262g of ammonium dihydrogen phosphate, 3.4226g of aluminum oxide, 4.0981g of zinc oxide, 4.1997g of calcium carbonate, 4.4473g of sodium carbonate, and 0.0627g of terbium oxide according to the composition of the above-mentioned luminescent glass. g, dysprosium oxide 0.0783g, these raw materials are fully ground and mixed to obtain glass batch material;

[0051] (2) Melting: Pour the glass batch into a corundum crucible, heat up to 1550°C at a heating rate of 5°C / min under air atmosphere, and melt at 1550°C for 1 hour to obtain molten glass; 2) The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com