Cutter cabinet for conveniently storing and taking cutters

A tool cabinet and tool technology, applied in the field of tool cabinets, can solve the problems of being unsuitable for the storage of precision tool spare parts, wasting capital and interest, and hindering the appearance of the warehouse, so as to achieve convenient and fast access to items, reduce overhead costs, and reduce tool preparation. effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

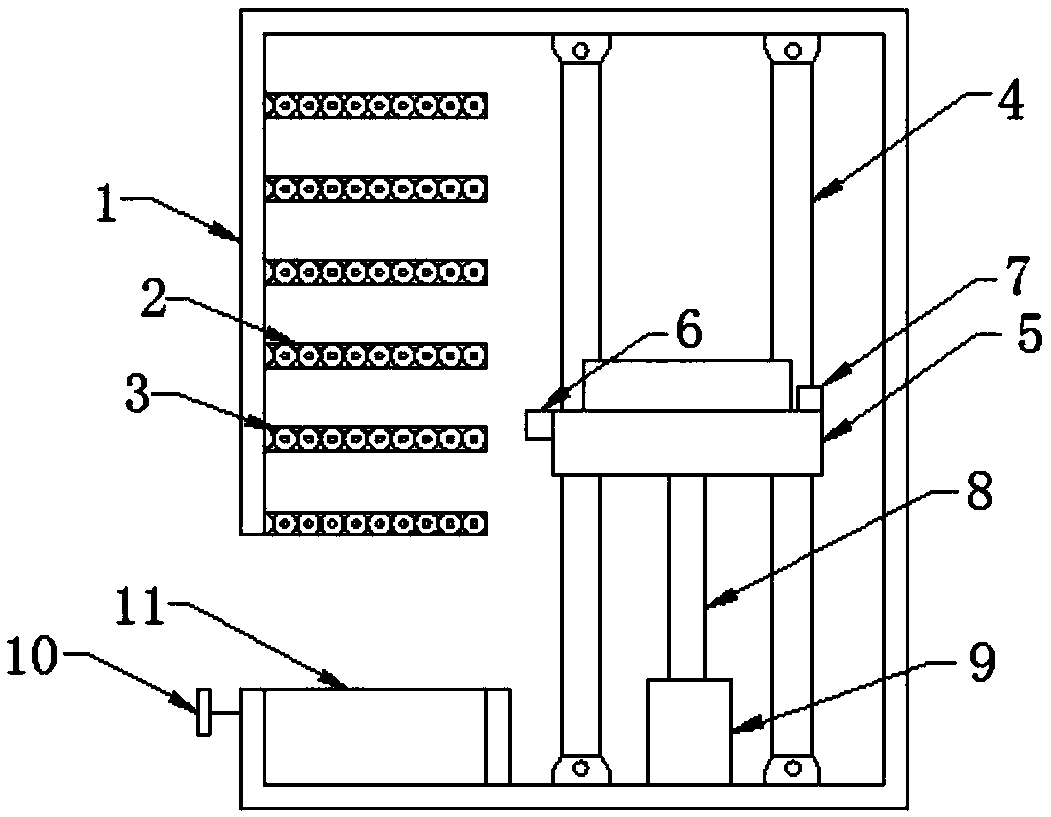

[0017] Such as figure 1 As shown, the present invention provides a tool cabinet for easy access to tools, including a cabinet body 1, one side of the cabinet body 1 is provided with a bracket 2, the inside of the bracket 2 is provided with a guide roller 3, and the inside of the bracket 2 is provided with a bracket 2 A support rod 4 is provided on one side, a tray 5 is sleeved on the outside of the support rod 4, a displacement sensor 6 is provided on one side of the tray 5, a manipulator 7 is provided on the other side of the tray 5, and a telescopic rod 8 is connected to the bottom end of the tray 5 , the bottom of the telescopic rod 8 is connected with a cylinder 9, and the bottom of the bracket 2 is provided with a delivery port 11.

[0018] Further, a PLC control panel 10 is provided on the side of the delivery port 11, and the PLC control panel 10 is located outside the cabinet body 1, and the automatic lifting of the pallet 5 can be controlled by the PLC control panel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com