Hardware plate surface quick-polishing device

A polishing device and plate technology, applied in the direction of grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems of unguaranteed polishing rate, deep polishing damage layer, poor polishing effect, etc., and achieve good polishing effect and high polishing speed Faster, lower output effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

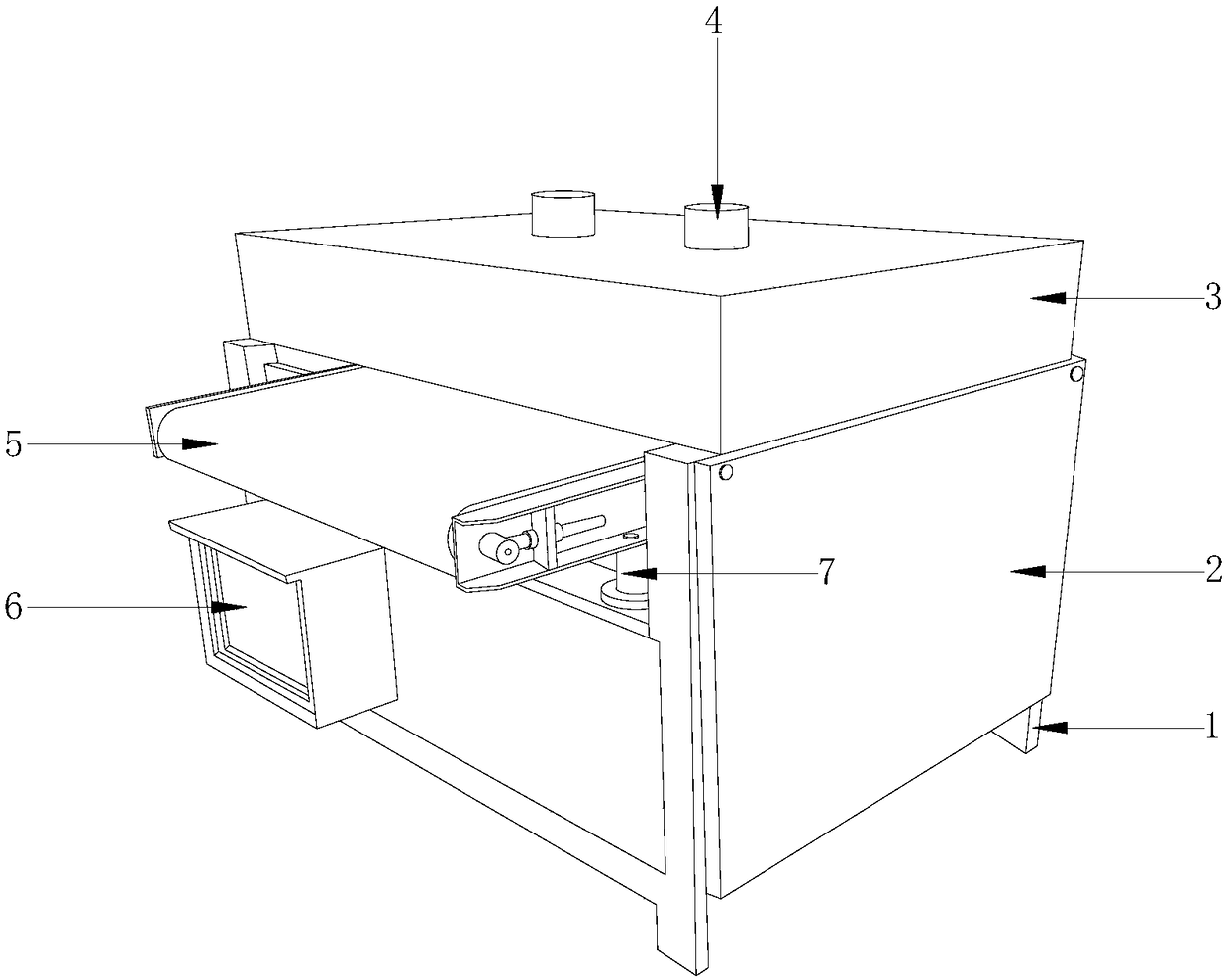

[0021] Such as Figure 1-Figure 5As shown, the present invention provides a rapid polishing device for the surface of a metal plate, the structure of which includes: a supporting column 1, a polishing mechanism 2, a protective cover 3, a manhole 4, a longitudinal moving plate 5, an electric control box 6, and a fixed pile 7, The supporting columns 1 are provided with four and are evenly installed on the bottom of the polishing mechanism 2 and welded together. The polishing mechanism 2 is vertically fixed on the lower end of the protective cover 3 and is mechanically connected with the longitudinal moving plate 5. The protective The cover 3 has a rectangular cross-section and is vertically nested on the top of the polishing mechanism 2 and matched. The manhole 4 is provided with two cuts evenly attached to the top of the protective cover 3 and welded together. The protective cover 3 and The manhole 4 is an integrated structure, the longitudinal moving plate 5 is horizontally em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com