Locating device for annular workpiece

A technology for positioning devices and workpieces, applied in positioning devices, metal processing machinery parts, manufacturing tools, etc., can solve the problems of affecting the processing accuracy, the inability to process the side of the workpiece, and the skewing of the workpiece clamping, etc., to achieve firm clamping and contact The effect of many faces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

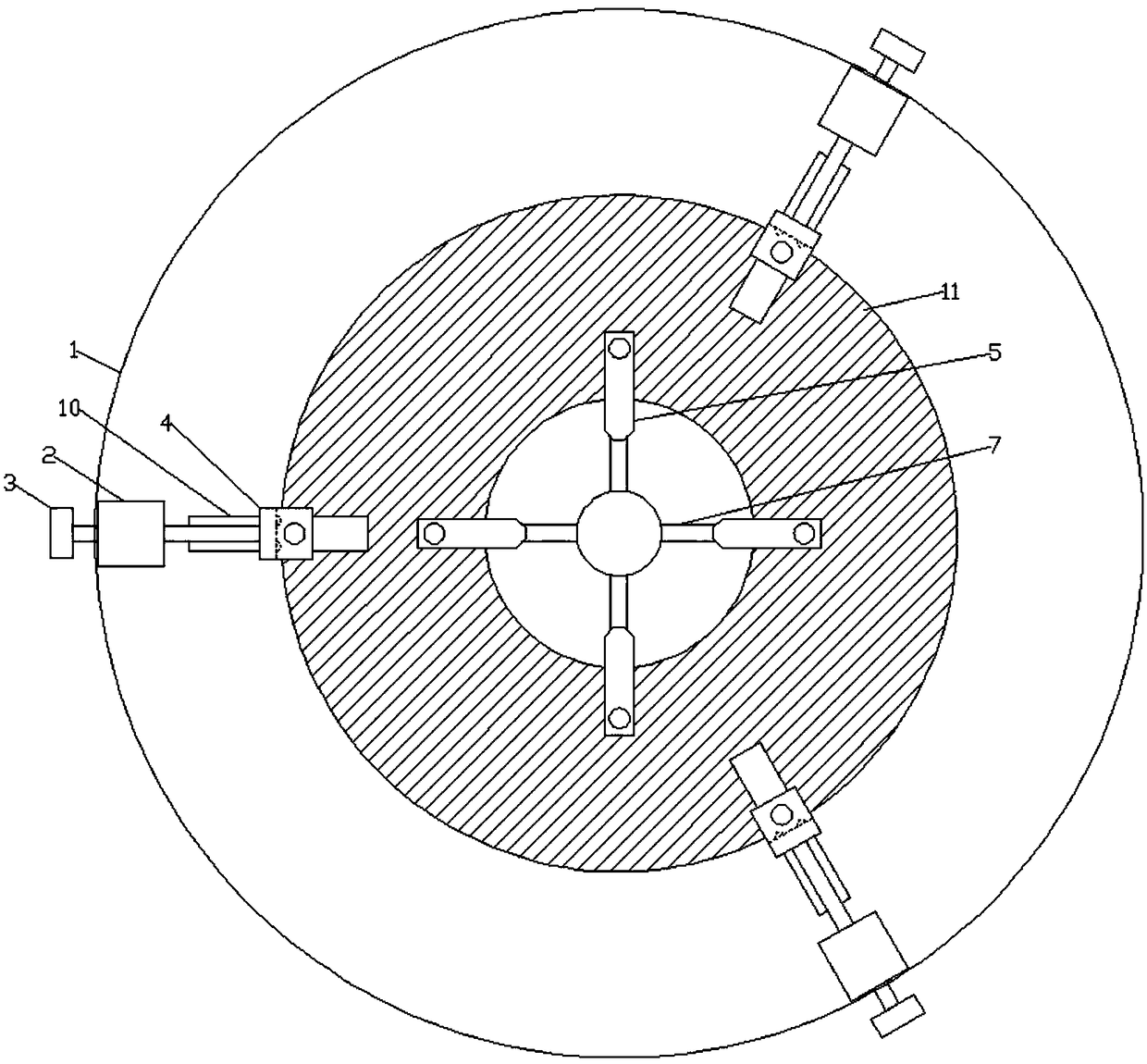

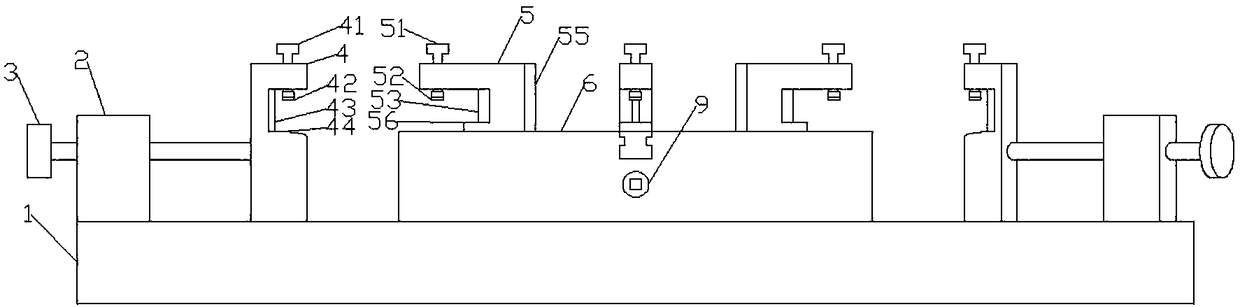

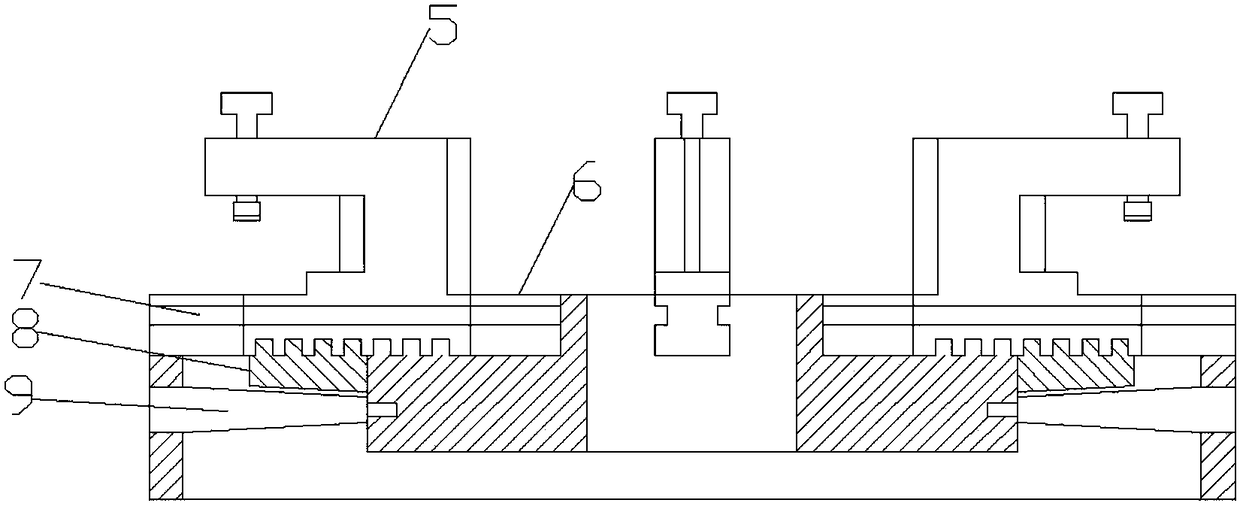

[0018] Figure 1-6 Show the specific embodiment of the present invention: a kind of positioning device of circular ring type workpiece, comprises chassis 1, and described chassis 1 is provided with three chute-10s that are evenly distributed about the center of chassis 1 circle, and described chute-10 is provided with There is a clamp block one 4 that is slidingly connected, and the chassis 1 is also provided with three fixed seats 2 and are all located on one side of the chute one 10, and the fixed seat 2 is provided with a threaded rotating rod 3, and the rotating rod 3 is arranged on the fixed seat 2. The front end of the rod 3 is connected with the clamping block one 4, the clamping block one 4 is a concave structure, the upper end is provided with a threaded pressure rod one 41, the lower end of the pressure rod one 41 is provided with a pressure head one 42, and the pressure rod one 41 lower end is provided with a pressure head one 42. The bottom of the head one 42 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com