Mesh model Walsh modeling method for aircraft flutter analysis

A grid model, flutter analysis technique, used in aerospace and information fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

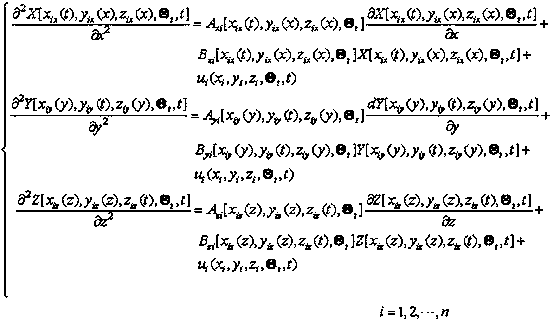

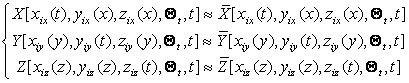

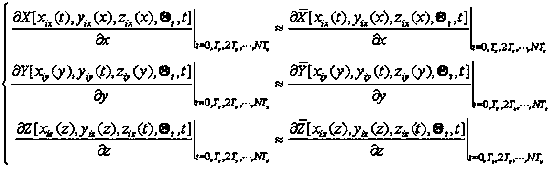

[0058] Step 1: Take the axis system of the aircraft body Analyzing complex flutter models, selecting grid points, the coordinates are: , when the vibration grid point coordinates for time and other two-axis position functions, in order to express the first grid points at The vibration component of the shaft, with For example, the subscript Label the grid point, the second letter of the subscript Respectively represent the vibration in the shafting of the body The three axis components of ; in order to simplify the problem, consider the first grid points at When vibrating in the axial direction, Consider the first grid points at When vibrating in the axial direction, , , considering the first grid points at When vibrating in the axial direction, ; For ease of writing, the , and abbreviated as , and ; The approximate model established in the neighborhood of grid points is:

[0059]

[0060] Formula 1

[0061] In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com