Optical fiber sensor with air membrane cooling function

An optical fiber sensor and air film cooling technology, which is applied to instruments, optical devices, measuring devices, etc., can solve the problems of manual operation, cleaning products cannot be reused, and fiber probe cleaning, etc., and achieves reasonable and novel design. Simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

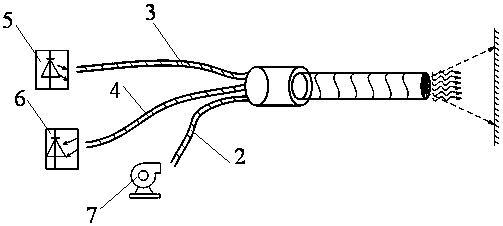

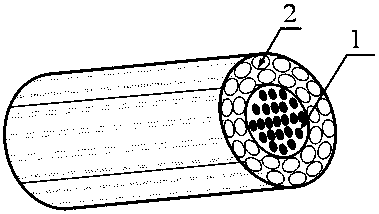

[0014] like Figure 1-2 As shown, the present invention is a fiber optic sensor with film cooling. Taking a reflective optical fiber displacement sensor as an example, the sensor includes a reflective optical fiber displacement sensor probe 1, a capillary catheter 2, a light source 5, a photoelectric converter 6 and a Adjust the gas pump 7, the capillary conduit 2 is tightly fixed on the periphery of the reflective optical fiber displacement sensor probe 1 in a symmetrical distribution form, and the capillary conduit 2 is tightly fixed on the reflective optical fiber displacement sensor probe in the form of bonding, single-turn or multi-turn 1 periphery, the end face...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com