General-purpose product taking tool for injection molding process

A tooling and process technology, applied in the field of general-purpose tooling for injection molding, can solve the problems of long production cycle, high management and use cost, and difficult to change of traditional tooling, and achieve the effect of simple structure, convenient production, and reduced quantity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

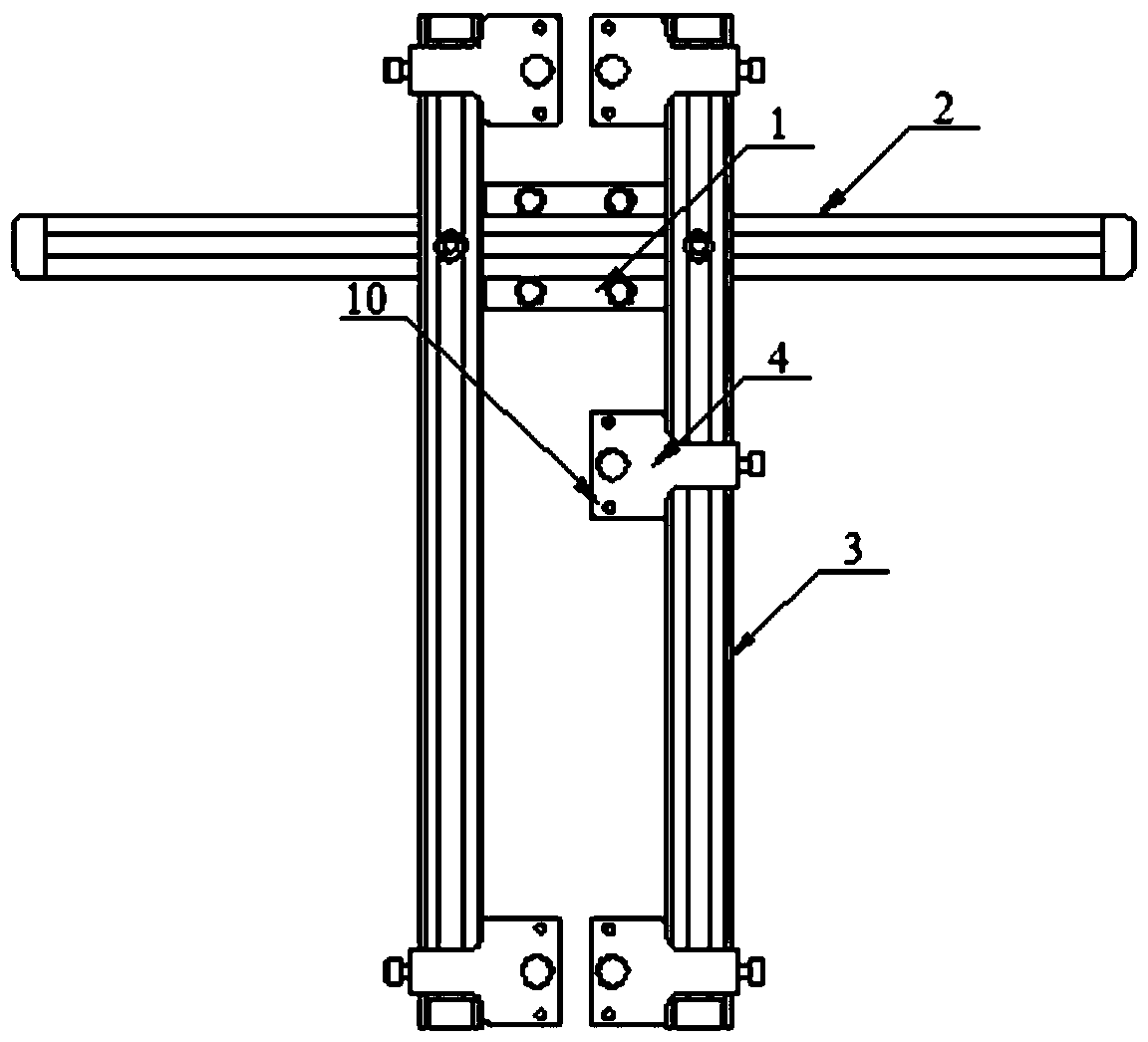

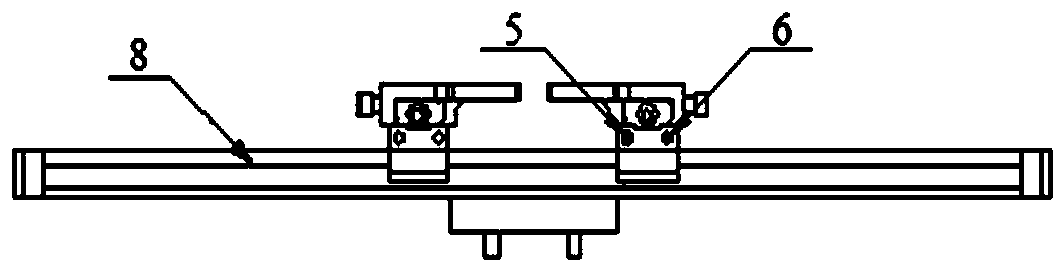

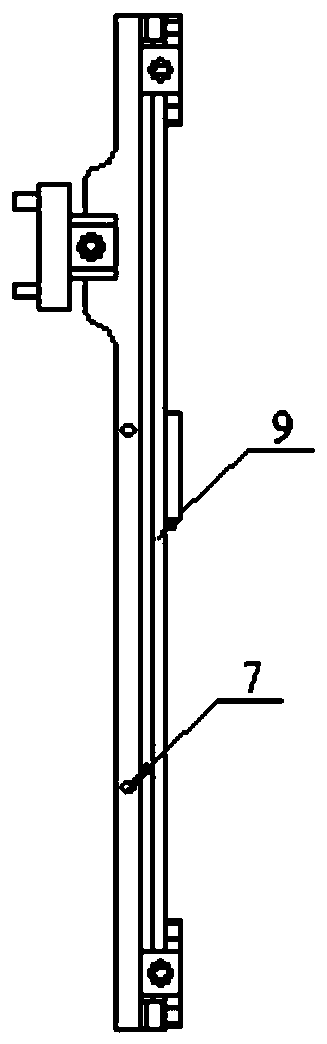

[0036] The specific implementation of the universal pick-up tool for the injection molding process of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0037] Referring to the accompanying drawings, the general pick-up tooling for injection molding process includes a fixed seat 1, a support arm 2 and other components. The fixed seat 1 is used to be installed on the mechanical arm of the injection molding equipment. There are 3-5 working arms 3, 2 in the figure, the specific number and position of the working arms 3 can be adjusted according to the different structures of the products, so that the products can be taken out stably and firmly. The working arm 3 and the supporting arm 2 are vertically arranged, the working arm 3 is arranged on the working arm 3 through a sliding mechanism, and the working arm 3 can slide on the supporting arm 2 under driving. This mode can be more widely adapted to different product structures...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com