Alkaline furnace flue gas wet process denitration process and device capable of cyclically utilizing absorbent

A technology of wet denitrification and absorbent, applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of secondary pollution of operation cost, wide application of wet denitrification, and no application, so as to reduce investment cost , Improve utilization and reduce consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

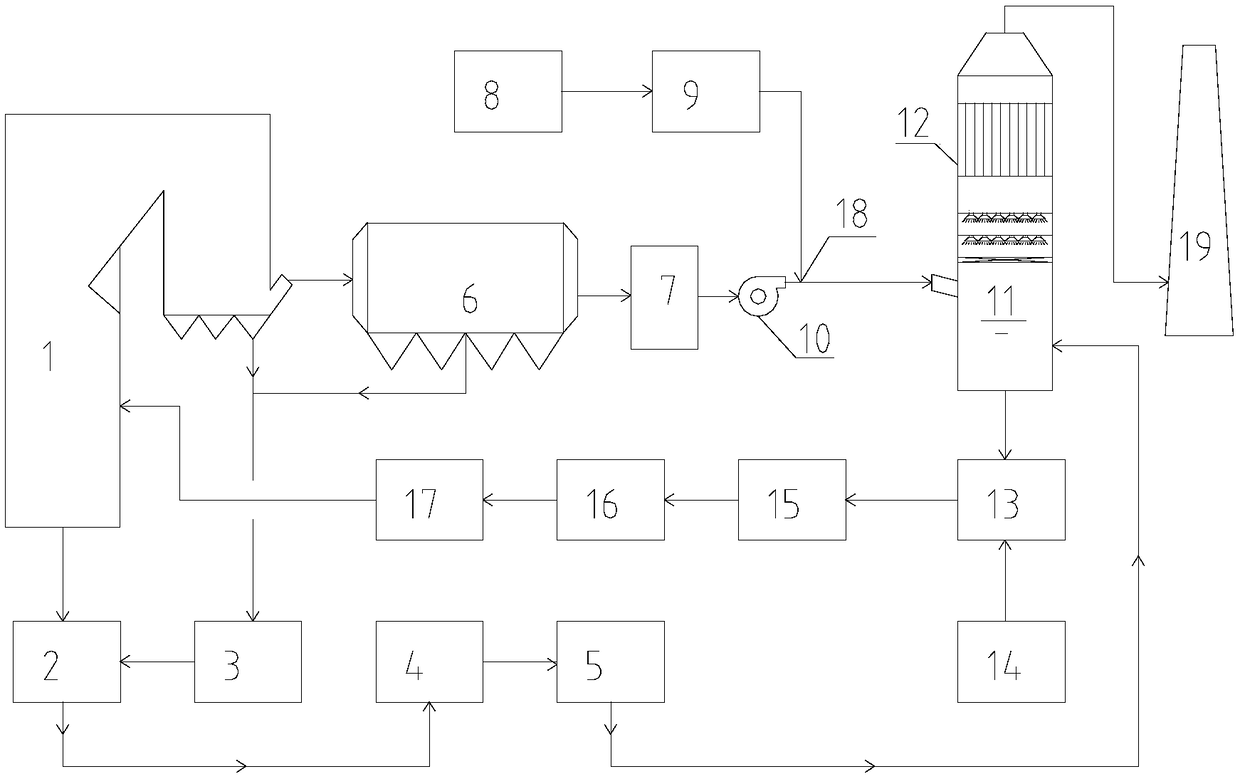

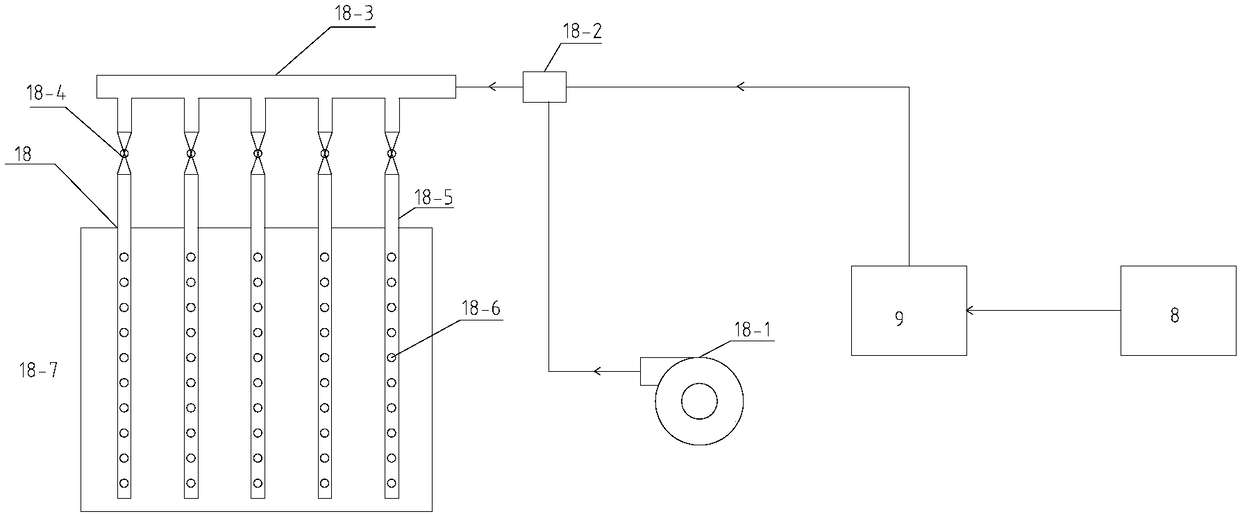

[0075] A 1440TDS / D alkali recovery furnace with a flue gas volume of 280800m 3 / h, NOx280mg / Nm 3 , SO 2 30mg / Nm 3 Dust concentration 30mg / Nm 3 The initial flue gas passes through the ultra-low emission process. The temperature of the smoke at the place where ozone is sprayed is 150°C, and the molar ratio of ozone to nitrogen oxides in the smoke is n O3 :n NO =0.8; the ozone concentration that sprays into is 2%; Sodium sulfide and sodium hydroxide mol ratio are 0.2, and the pH value control range in the spray absorption tower is 8, and the supplementary quantity mol ratio of sodium sulfide is n NO :n Na2S =6, the salt concentration TDS of the discharged waste water is controlled at 100000mg / l, the molar ratio of the amino group in the chemical denitrification agent to the nitrite in the waste water is 0.8, and a wet electrostatic precipitator is installed on the top of the spray tower. Spray tower outlet NOx 63mg / Nm 3 , SO 2 2.5mg / Nm 3 , Dust concentration 4.3mg / Nm ...

Embodiment 2

[0077] A 1440TDS / D alkali recovery furnace with a flue gas volume of 280800m 3 / h, NOx280mg / Nm 3 , SO 2 30mg / Nm 3 Dust concentration 30mg / Nm 3 The initial flue gas passes through the ultra-low emission process. The temperature of the smoke at the place where ozone is sprayed is 130°C, and the molar ratio of ozone to nitrogen oxides in the smoke is n O3 :n NO =0.7; The ozone concentration of spraying is 4%; Sodium sulfide and sodium hydroxide mol ratio are 0.6, and the pH value control range in the packed absorption tower is 12, and the supplementary quantity mol ratio of sodium sulfide is n NO :n Na2S = 4, the salt concentration TDS of the discharged waste water is controlled at 110000mg / l, the molar ratio of the amino group in the chemical denitrification agent to the nitrite in the waste water is 0-1, and the top of the packed tower is equipped with a wet electrostatic precipitator. Spray tower outlet NOx 85mg / Nm 3 , SO 2 5mg / Nm 3 , Dust concentration 3.7mg / Nm 3 ...

Embodiment 3

[0079] A 1440TDS / D alkali recovery furnace with a flue gas volume of 280800m 3 / h, NOx280mg / Nm 3 , SO 2 30mg / Nm 3 Dust concentration 30mg / Nm 3 The initial flue gas passes through the ultra-low emission process. The temperature of the smoke at the place where ozone is sprayed is 100°C, and the molar ratio of ozone to nitrogen oxides in the smoke is n O3 :n NO =0.5; the concentration of ozone injected is 1%; the mol ratio of sodium sulfide to sodium hydroxide is 0.1, the pH value control range in the spray absorption tower is 6, and the replenishing amount mol ratio of sodium sulfide is n NO :n Na2S =8, the salt concentration TDS of the discharged wastewater is controlled at 200,000 mg / l, the molar ratio of the amino group in the chemical denitrification agent to the nitrite in the wastewater is 0.8, and a high-efficiency demister is installed on the top of the spray tower. Spray tower outlet NOx 153mg / Nm 3 , SO 2 6.1mg / Nm 3 , Dust concentration 7.5mg / Nm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com