Organic rankine cycle air inflow supercharging internal combustion engine system and method

A Rankine cycle, intake boosting technology, applied in the direction of internal combustion piston engine, machine/engine, mechanical equipment, etc., can solve the problems of complicated system and large heat loss, achieve high efficiency and environmental protection of the system, small loss of working power, The effect of small heat exchange temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

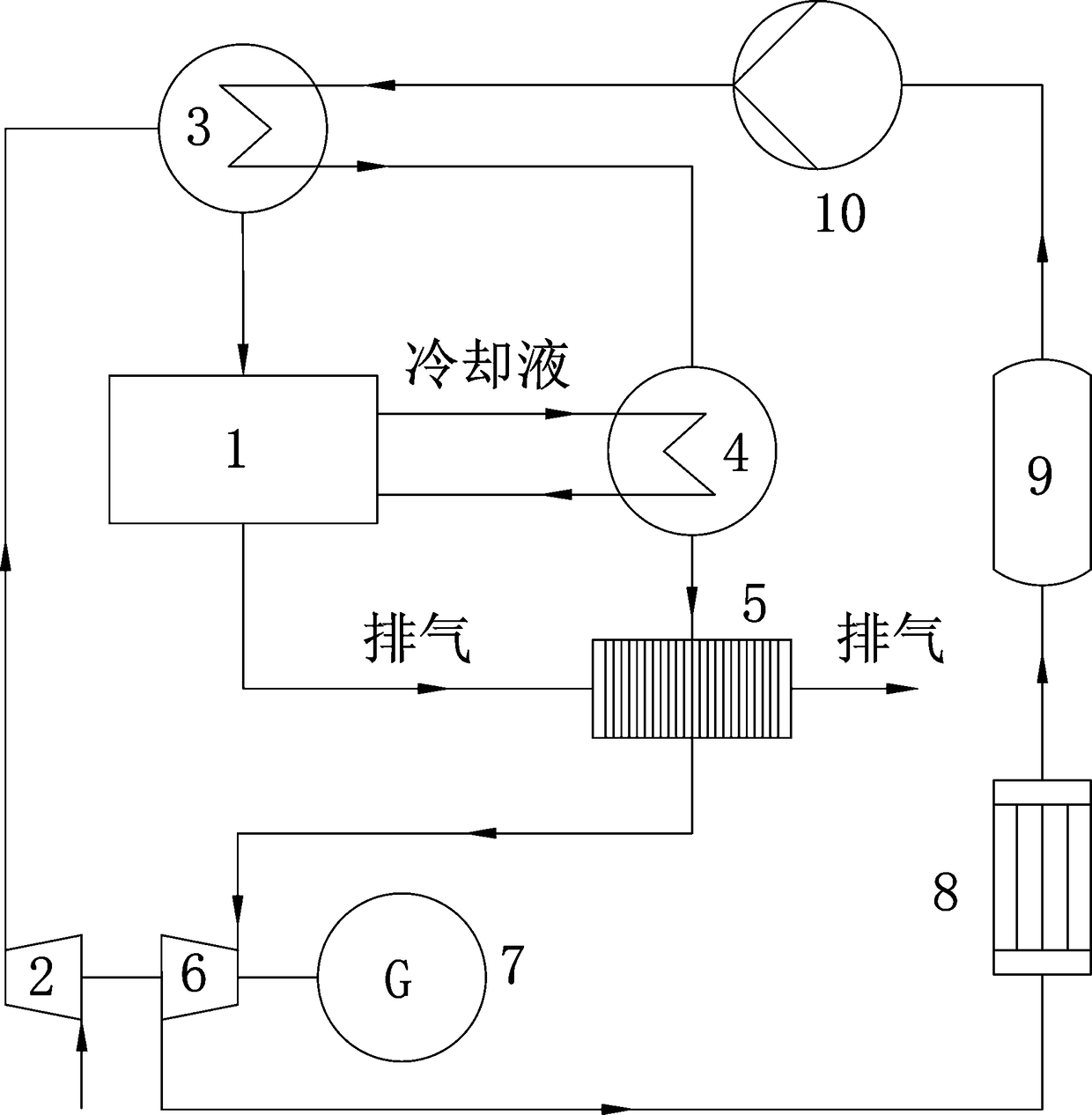

[0025] Such as figure 1 as shown, figure 1 It is a schematic diagram of the overall structure of the system. The organic Rankine cycle air intake supercharged internal combustion engine system, the organic Rankine cycle is ORC, including: internal combustion engine 1, compressor 2, intercooler 3, preheater 4, evaporator 5, expander 6 , generator 7, condenser 8, liquid storage tank 9 and working medium pump 10.

[0026] The inlet of compressor 2 is connected to the outside air, the outlet of compressor 2 is connected to the first inlet of intercooler 3, the first outlet of intercooler 3 is connected to the inlet of internal combustion engine 1, and the second inlet of intercooler 3 is connected to the outlet of working medium pump 10 , the second outlet of the intercooler 3 is connected to the inlet of the preheater 4, the preheater 4 is connected to the second inlet of the evaporator 5, the exhaust outlet of the internal combustion engine 1 is connected to the first inlet of ...

Embodiment 2

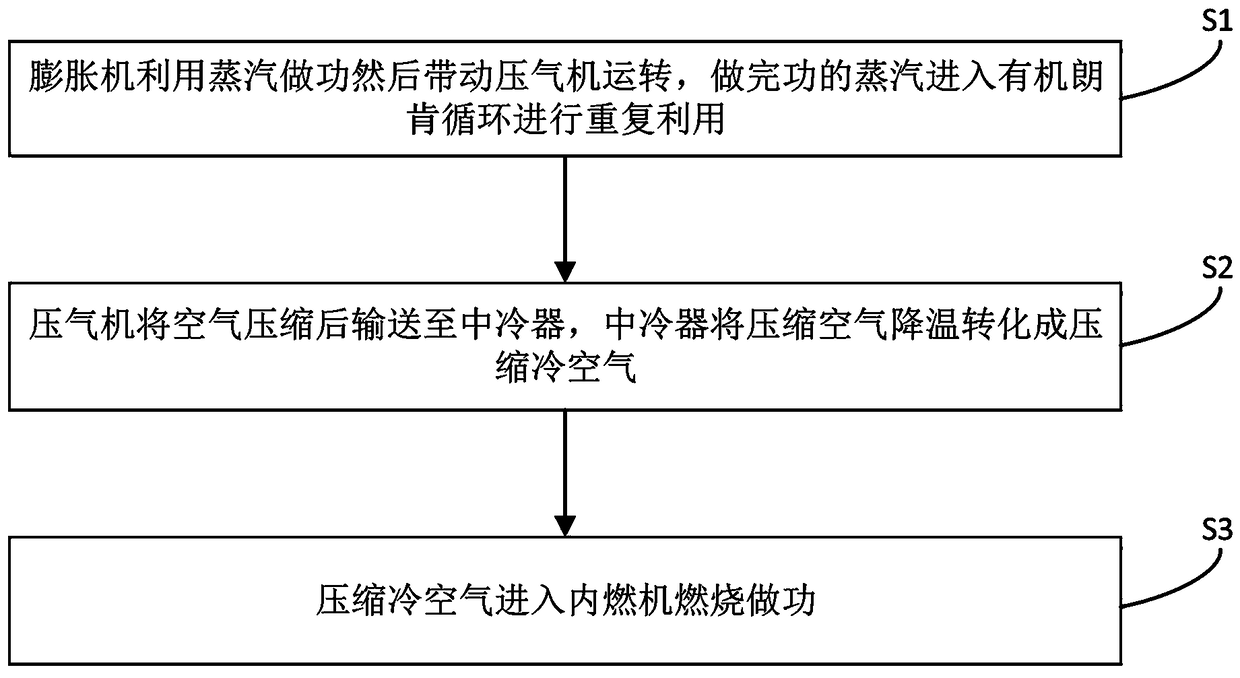

[0035] Such as figure 2 As shown, an organic Rankine cycle air intake supercharging method includes the following steps:

[0036] S1: The expander uses the steam to do work and then drives the compressor to run, and the steam that has done the work enters the organic Rankine cycle system for reuse.

[0037] The second outlet of the evaporator 5 is connected to the inlet of the expander 6, the expander 6 is respectively connected to the compressor 2 and the generator 7, the outlet of the expander 6 is connected to the inlet of the condenser 8, and the outlet of the condenser 8 is connected to the inlet of the liquid storage tank 9 , the outlet of the liquid storage tank 9 is connected with the inlet of the working fluid pump 10 . From this structure, it can be seen that the organic working medium absorbs heat in the evaporator 5 and becomes saturated steam or superheated steam, and then enters the expander 6 to expand and perform work. Part of the mechanical work output by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com