Building stone breaking and sorting device

A sorting device and construction technology, applied in road construction and construction fields, can solve the problems of transportation waste, increase procedures, waste of manpower and material resources, etc., and achieve the effects of improving production efficiency, reducing production costs, and avoiding duplication of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

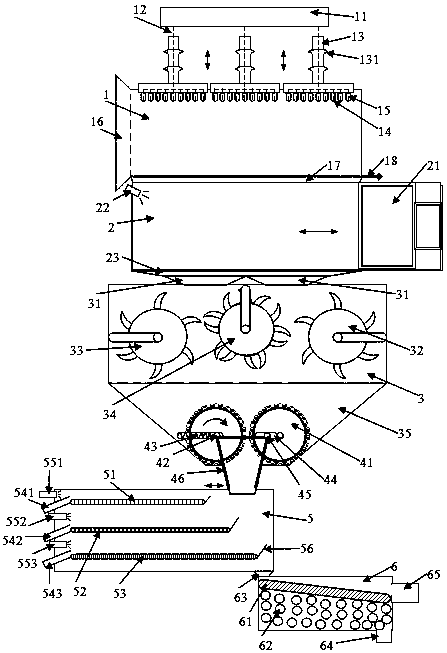

[0032] A device for crushing and sorting stones for construction, comprising an ultrasonic treatment chamber, an impact chamber, a crushing chamber, a sorting device, a drying transfer chamber and a water treatment device.

[0033] The ultrasonic treatment chamber includes an ultrasonic chamber shell, an ultrasonic generator, a wire, an ultrasonic treatment frame, an ultrasonic head, an ultrasonic needle, a stone entrance, an ultrasonic treatment chamber outlet, and an outlet opening and closing baffle; the stone entrance is arranged in the ultrasonic chamber On one side of the shell, an ultrasonic processing frame is arranged on the top of the ultrasonic chamber shell. There are three ultrasonic processing frames, all of which are in an inverted "T" shape. Each of the ultrasonic processing frames includes an upper vertical frame and a lower horizontal frame. The processing frame, the horizontal processing frame is placed horizontally on the top of the ultrasonic chamber shell ...

Embodiment 2

[0048] A device for crushing and sorting stones for construction, comprising an ultrasonic treatment chamber, an impact chamber, a crushing chamber, a sorting device, a drying transfer chamber and a water treatment device.

[0049] The ultrasonic treatment chamber includes an ultrasonic chamber shell, an ultrasonic generator, a wire, an ultrasonic treatment frame, an ultrasonic head, an ultrasonic needle, a stone entrance, an ultrasonic treatment chamber outlet, and an outlet opening and closing baffle; the stone entrance is arranged in the ultrasonic chamber On one side of the shell, an ultrasonic processing rack is arranged on the top of the ultrasonic chamber shell. The ultrasonic processing racks are in 3 groups, 2 in each group, 6 in total, all in an inverted "T" shape structure, and each of the ultrasonic processing racks includes The upper vertical frame and the lower horizontal processing frame, the horizontal processing frame is placed horizontally on the top of the ul...

Embodiment 3

[0063] A device for crushing and sorting stones for construction, comprising an ultrasonic treatment chamber, an impact chamber, a crushing chamber, a sorting device, a drying transfer chamber and a water treatment device.

[0064] The ultrasonic treatment chamber includes an ultrasonic chamber shell, an ultrasonic generator, a wire, an ultrasonic treatment frame, an ultrasonic head, an ultrasonic needle, a stone entrance, an ultrasonic treatment chamber outlet, and an outlet opening and closing baffle; the stone entrance is arranged in the ultrasonic chamber On one side of the shell, an ultrasonic processing frame is arranged on the top of the ultrasonic chamber shell. There are five ultrasonic processing frames, all of which are in an inverted "T" shape. Each of the ultrasonic processing frames includes an upper vertical frame and a lower horizontal frame. The processing frame, the horizontal processing frame is placed horizontally on the top of the ultrasonic chamber shell a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com