Polyvinyl chloride kitchen and bathroom board and preparation method thereof

A technology of polyvinyl chloride and polyethylene wax, which is applied in the field of polyvinyl chloride kitchen and bathroom boards and its preparation, can solve problems such as the inability to achieve large-scale stable and unified production, the boards are brittle and easy to break, and the density cannot be reduced. Avoid the effect of loose board, lower product density and more air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

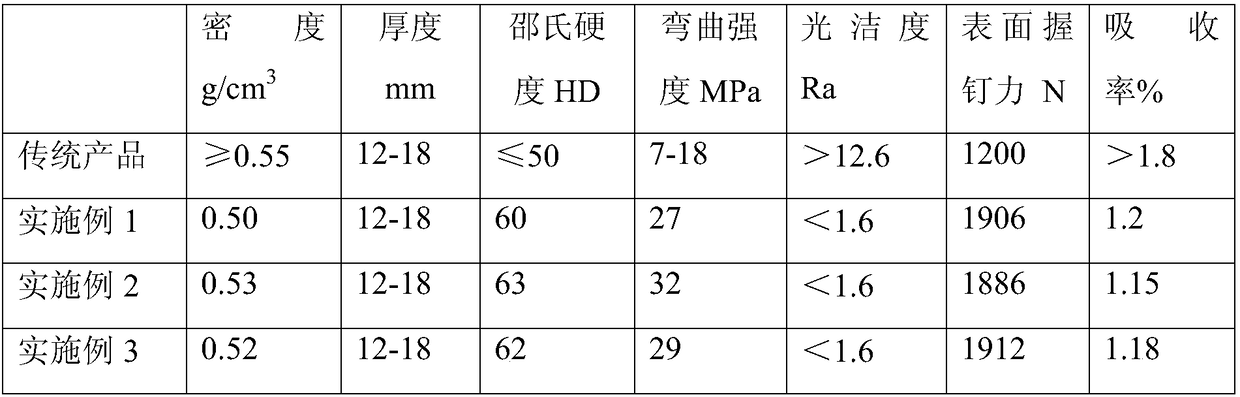

Examples

Embodiment 1

[0017] The polyvinyl chloride kitchen and bathroom board is composed of the following raw materials in parts by weight: 60 parts of polyvinyl chloride SG8 type resin, 40 parts of heavy calcium, 20 parts of recycled materials, 7 parts of foam regulator P90, 2.7 parts of lead salt stabilizer 0.5 parts, internal lubricant SP-60 0.2 parts, polyethylene wax 0.2 parts, micronized polyethylene wax N-14P 0.2 parts, plasticizer OA6 0.1 parts, exothermic AC foaming agent 0.5 parts, endothermic type NS- 1.2 parts of 603 foaming agent, 0.15 parts of fluorescent whitening agent, and 1 part of rutile; among them, heavy calcium needs to be activated before use.

[0018] The preparation method of described polyvinyl chloride kitchen and toilet board, comprises the following steps:

[0019] Put the materials into the hot mixing pot in the order of recycled material-plasticizer-polyvinyl chloride resin-heavy calcium-regulator-polyvinyl chloride resin-heavy calcium-recycled material, stir and he...

Embodiment 2

[0021] The polyvinyl chloride kitchen and bathroom board is composed of the following raw materials in parts by weight: 80 parts of polyvinyl chloride SG8 type resin, 60 parts of heavy calcium, 40 parts of recycled materials, 9 parts of foam regulator P90, 2.9 parts of lead salt stabilizer 0.6 parts, internal lubricant SP-60 0.3 parts, polyethylene wax 0.3 parts, micronized polyethylene wax N-14P 0.25 parts, plasticizer OA6 0.15 parts, exothermic AC foaming agent 0.6 parts, endothermic type NS- 1.4 parts of 603 foaming agent, 0.2 parts of fluorescent whitening agent, and 2 parts of rutile; among them, heavy calcium needs to be activated before use.

[0022] The preparation method of described polyvinyl chloride kitchen and toilet board, comprises the following steps:

[0023] Put the materials into the hot mixing pot in the order of reclaimed material-plasticizer-polyvinyl chloride resin-heavy calcium-regulator-polyvinyl chloride resin-heavy calcium-recycled material, stir for...

Embodiment 3

[0025] The polyvinyl chloride kitchen and bathroom board is composed of the following raw materials in parts by weight: 70 parts of polyvinyl chloride SG8 type resin, 50 parts of heavy calcium, 30 parts of recycled materials, 8 parts of foam regulator P90, 2.8 parts of lead salt stabilizer 0.55 parts of internal lubricant SP-60, 0.25 parts of polyethylene wax, 0.23 parts of micronized polyethylene wax N-14P, 0.12 parts of plasticizer OA6, 0.55 parts of exothermic AC foaming agent, endothermic NS- 1.3 parts of 603 foaming agent, 0.18 parts of fluorescent whitening agent, and 1.5 parts of rutile; among them, heavy calcium needs to be activated before use.

[0026] The preparation method of described polyvinyl chloride kitchen and toilet board, comprises the following steps:

[0027] Put the materials into the hot mixing pot in the order of recycled material-plasticizer-polyvinyl chloride resin-heavy calcium-regulator-polyvinyl chloride resin-heavy calcium-recycled material, stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com