Integrated thermal insulation structure of existing building exterior wall and construction method

A technology for thermal insulation of external walls and existing buildings, applied in building components, building structure, thermal insulation, etc., can solve the problems of inability to ensure the safety of pasted tiles, shortened service life of thermal insulation boards, poor fire performance, etc. The effect of shearing area, increasing firmness, and concise construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

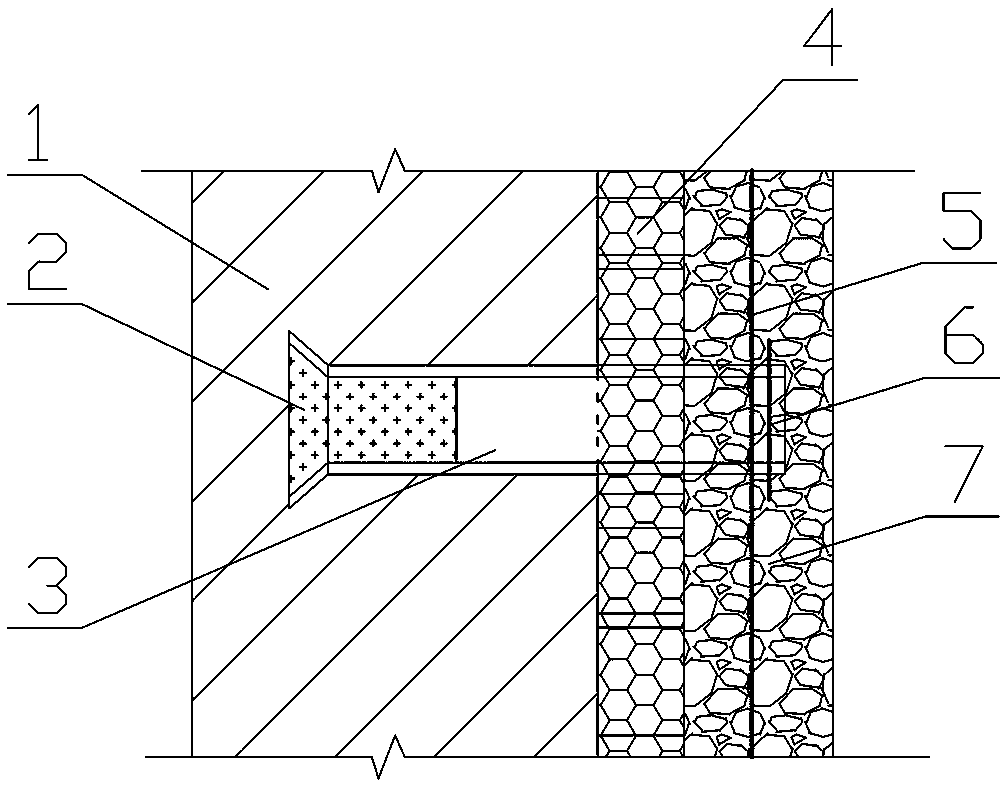

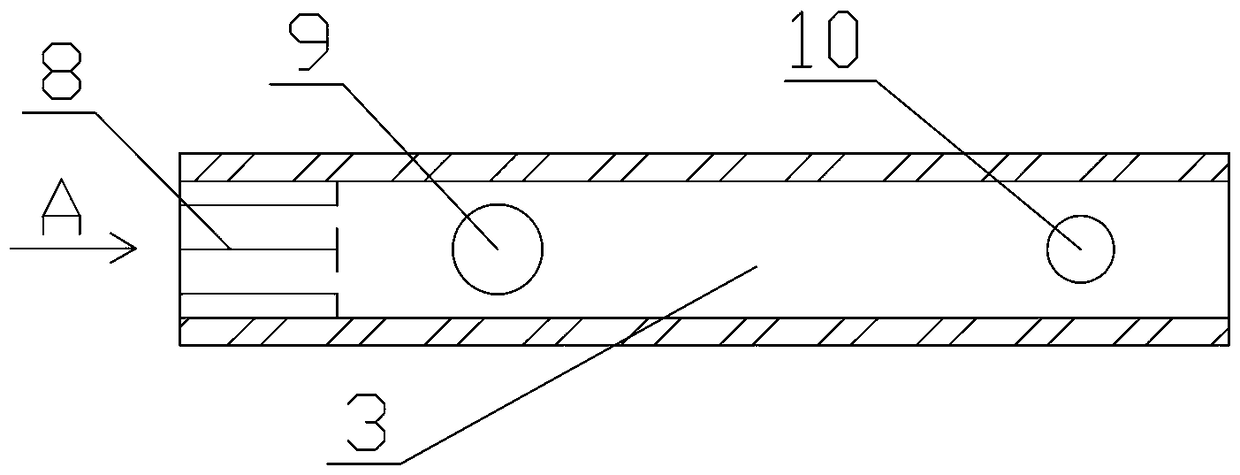

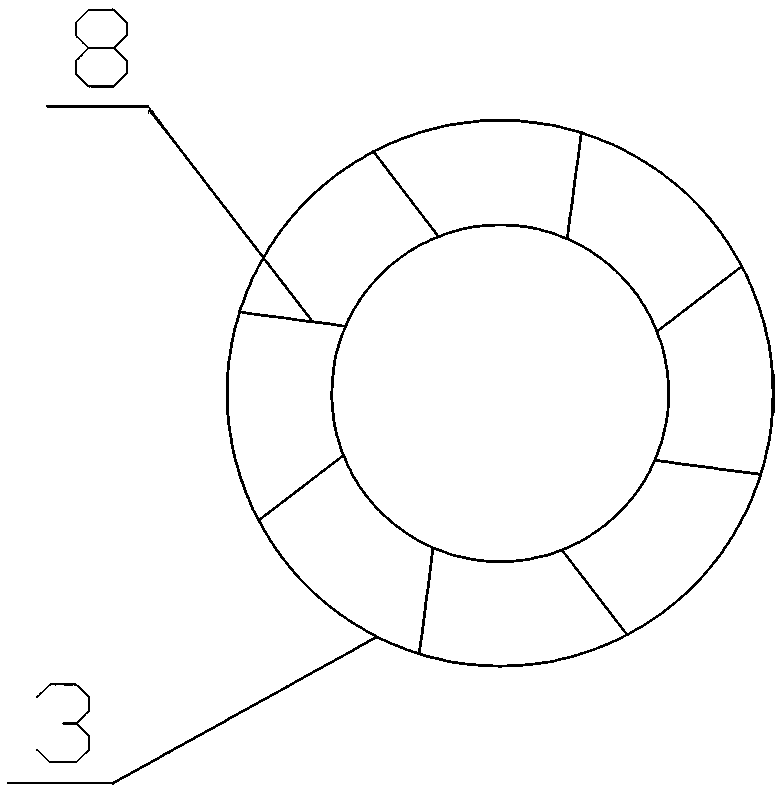

[0037] Embodiment 1: as Figure 1 to Figure 5 As shown, an existing building exterior wall thermal insulation integrated structure includes an existing wall 1, a thermal insulation board 4 and a surface layer 7, the inner side of the thermal insulation board 4 is arranged on the outer side of the existing wall 1, and the thermal insulation board 4 The outside is connected with the surface layer 7, and the interior of the surface layer 7 is longitudinally arranged with a grid-like steel mesh 5; the existing wall 1, the insulation board 4 and the surface layer 7 are all reserved with circular holes connected to each other. Both ends of the circular hole do not exceed both sides of the existing wall 1 and the surface layer 7, and a connecting pipe 3 is horizontally arranged in the circular hole; the connecting pipe 3 is a circular pipe, and the connecting pipe 3 is arranged on the The end face of the existing wall 1 is uniformly provided with slits 8, the connecting pipe 3 is pro...

Embodiment 2

[0044] Embodiment 2: as Figure 6 ~ Figure 11 The construction method of the existing building exterior wall insulation integrated structure based on the existing building exterior wall insulation integration structure shown includes the following procedures:

[0045] a) Drilling, drilling the connecting pipe 3 fixing hole 11 on the existing wall 1, the diameter of the fixing hole 11 is transitionally matched with the connecting pipe 3, and the fixing hole 11 is reamed near the inner side of the existing wall 1, The size of the reaming hole matches the pipe pad 2;

[0046] When drilling, the distance between the fixing holes 11 and the inner surface of the existing wall 1 is not less than 40mm, and the bidirectional distance between the fixing holes 11 is not more than 1000mm.

[0047] b Install the connecting pipe 3 and the pipe pad 2, place the pipe pad 2 on the end of the connecting pipe 3 with the slit 8, thread the tie rod 12 through the connecting pipe 3 and the threade...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com