Prefabricated sewage intercepting box culvert and construction method thereof

A prefabricated and box culvert technology, which is applied in the direction of buildings and road bottom layers, can solve the problems of construction safety hazards, long construction time and times, and exposed foundation pits, etc. It achieves good sealing effect, less difficulty in pouring, and high construction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

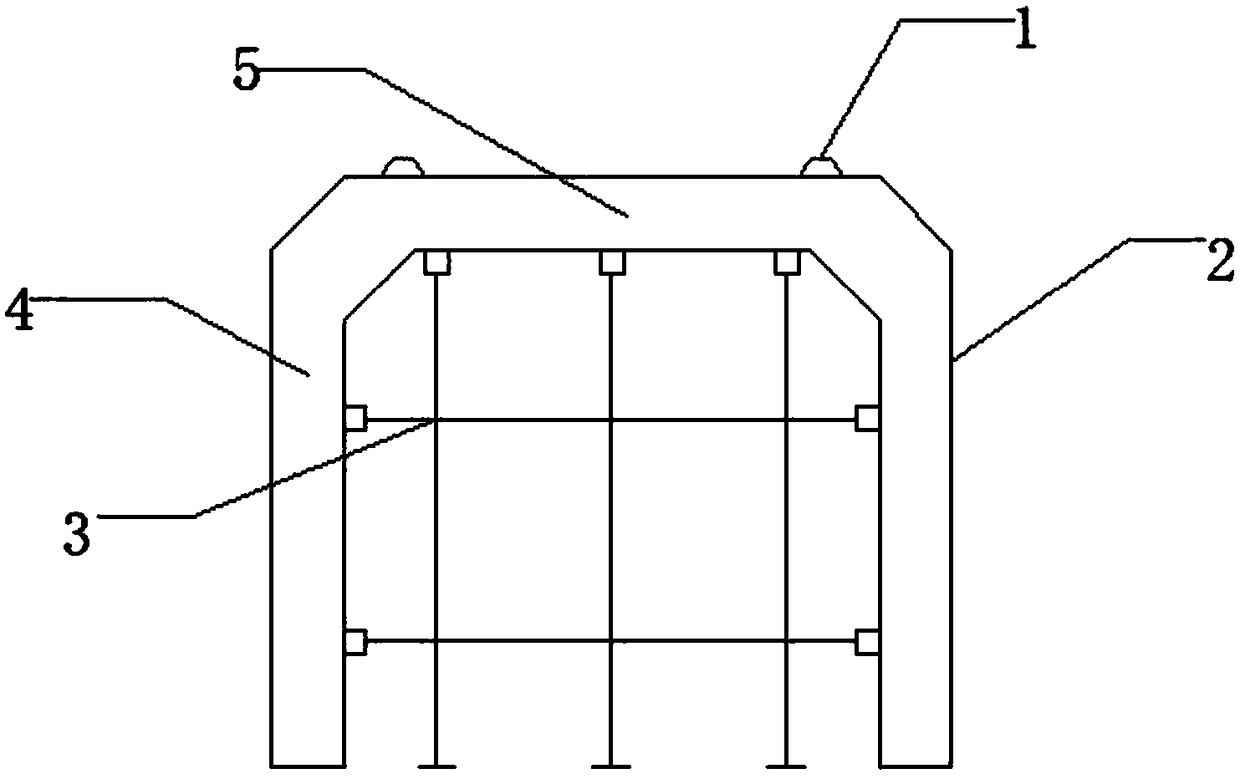

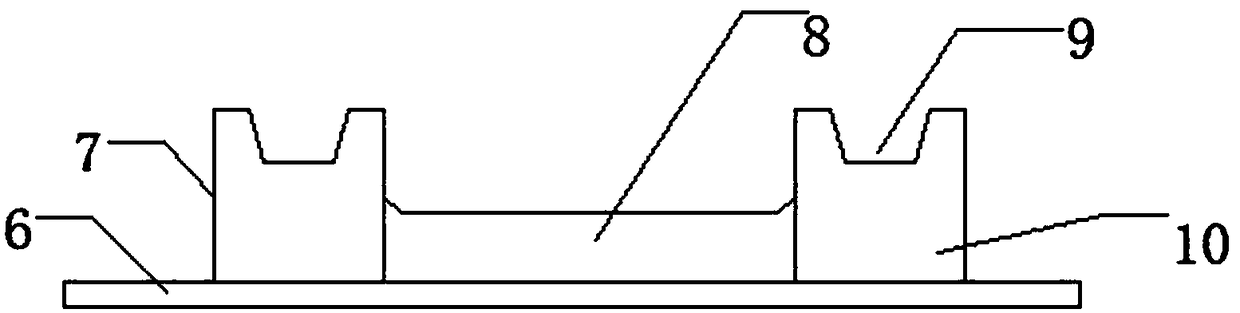

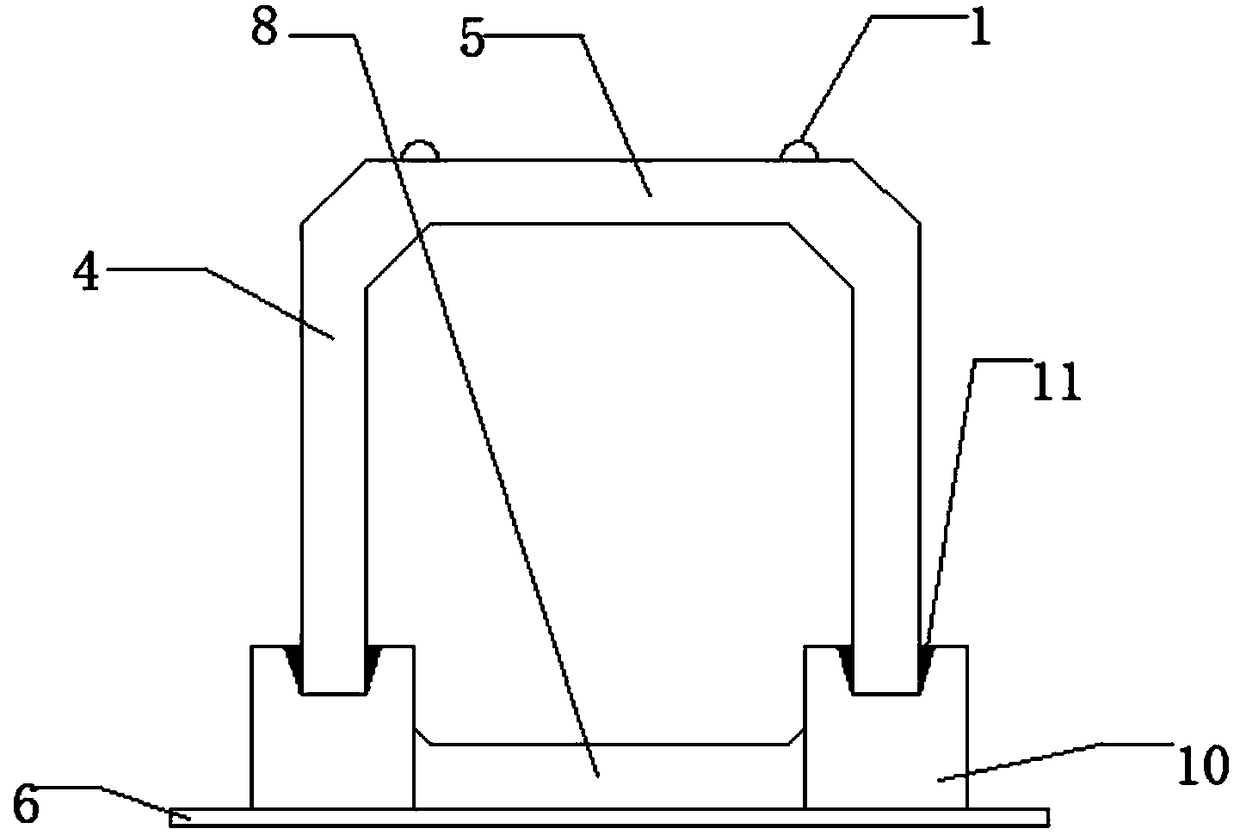

[0024] Such as image 3 As shown, a kind of assembled sewage intercepting box culvert comprises prefabricated sewage intercepting box culvert segment (in this embodiment, what adopt is the simplest two sewage intercepting box culvert segmental splicing, in fact, can also be three, four or even more) and cast-in-place cushion 6, cap 10 and bottom plate 8, the sewage intercepting box culvert segment includes the top plate 5 and side plate 4 forming the door shape, and the sewage intercepting box culvert segment is provided with There is a suspension ring 1, the platform 10 and the bottom plate 8 are located on the cushion layer 6, the bottom plate 8 is sandwiched between the platforms 10 and cast integrally with the platform 10, the top surface of the platform 10 is provided with a groove 9, and the bottom of the side plate 4 is inserted And supported on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com