Printing and dyeing device with dust removal and drying function

A technology of drying function and dust removal bag, applied in the field of printing and dyeing devices with dust removal and drying function, can solve the problems of high investment cost, large labor workload, poor dust removal and drying function, etc., and achieves small investment, small labor workload, dust removal and drying good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

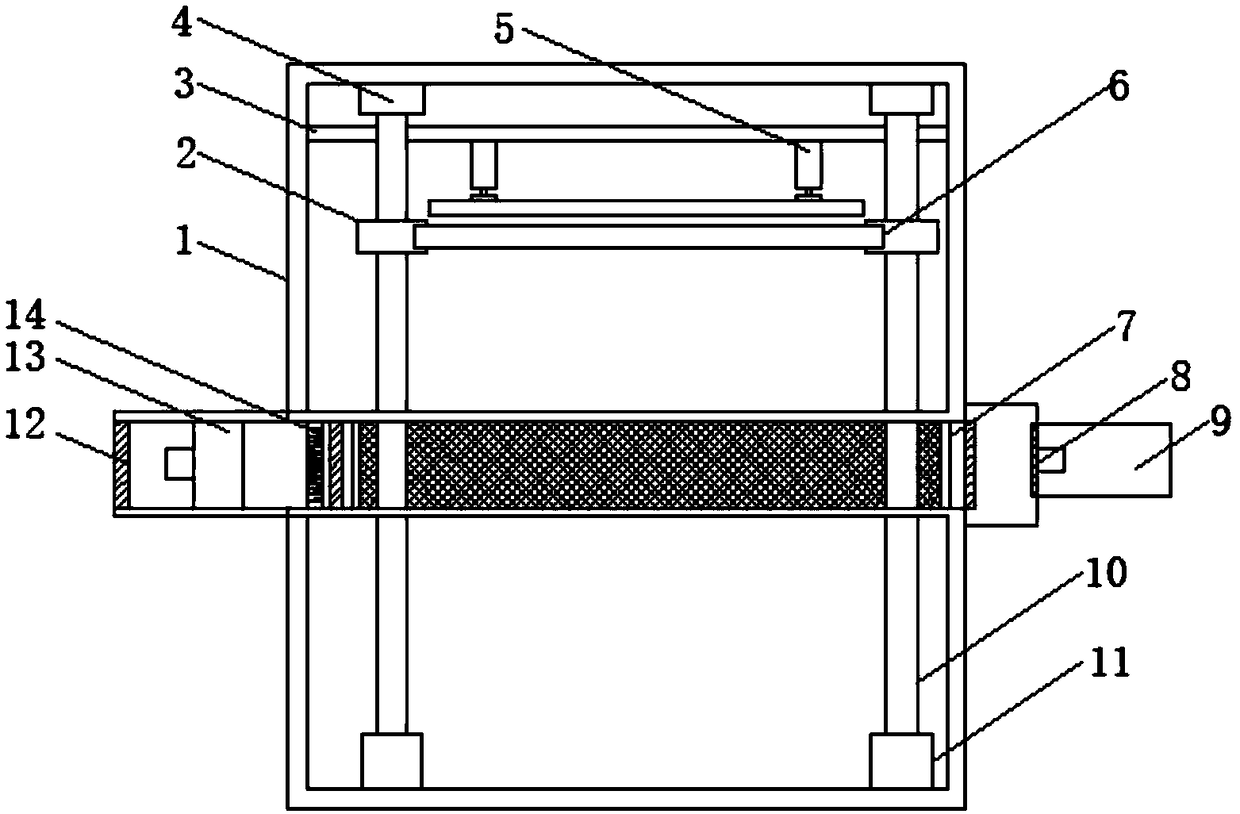

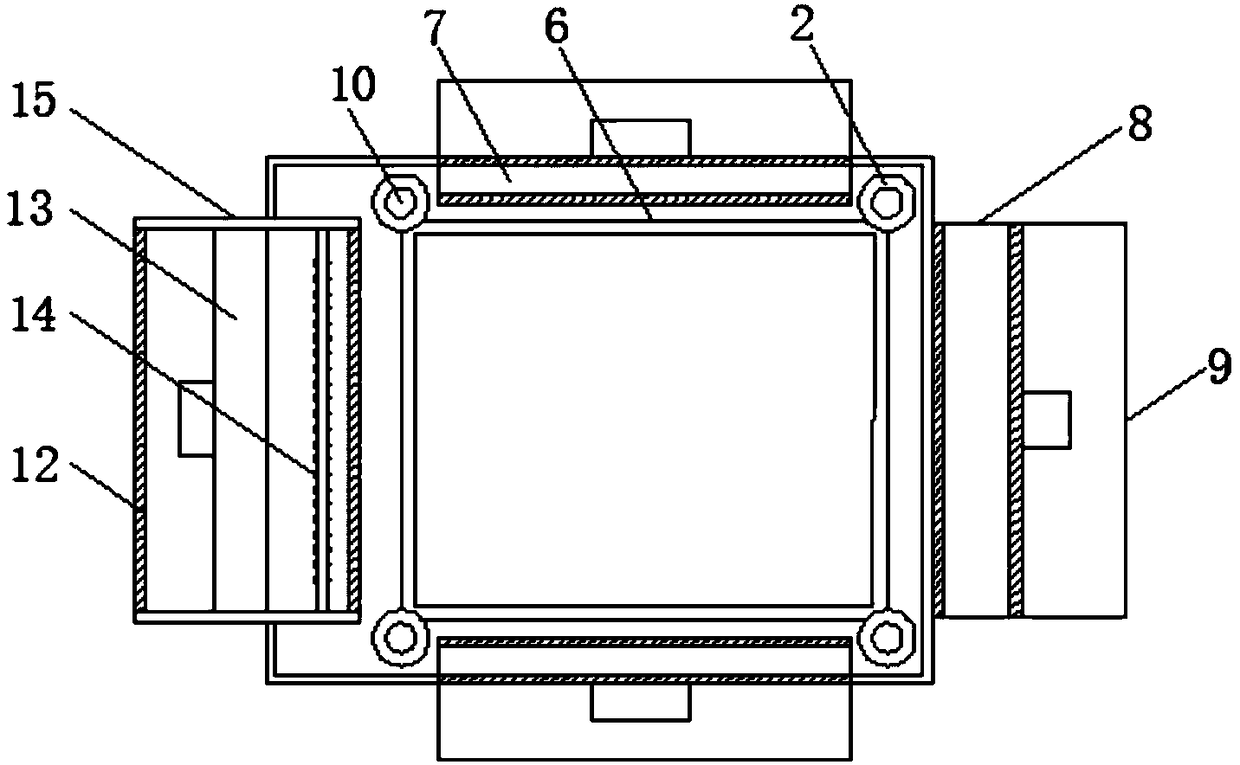

[0015] refer to Figure 1-2 , a printing and dyeing device with dust removal and drying functions, comprising a first box body 1, four limit blocks 4 in a rectangular array are welded on the top inner wall of the first box body 1, and the first box body 1 Four motor boxes 11 are welded on the inner wall of the bottom, and the motor boxes 11 are located directly below the limit block 4, and the drive motors are welded on the bottom inner wall of the motor boxes 11, between the limit block 4 and the motor box 11 Screw rods 10 are arranged between them, the tops of the screw rods 10 are movably installed in the limit block 4, the lower ends of the screw rods 10 are weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com