Preparation method and application of metal phosphide porous frame/graphene composite fiber

A composite technology of metal phosphide and graphene, which is applied to the chemical characteristics of fibers, textiles and papermaking, artificial filaments made of inorganic materials, etc., can solve the problems of low mechanical strength, electrical conductivity and flexibility, and achieve excellent electrochemical properties, The effect of uniform distribution of components and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

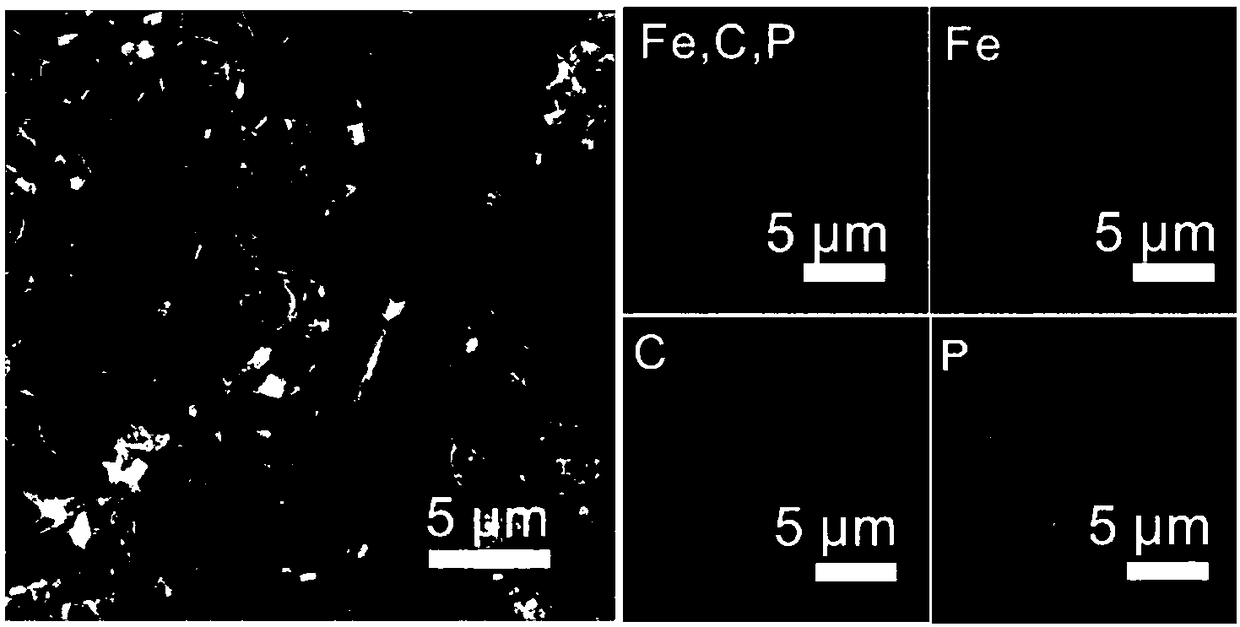

[0030] A kind of preparation method of porous metal phosphide / graphene composite fiber, comprises the following steps:

[0031] (1) Preparation of Fe-MOF crystal powder: Add 50 mL of N,N-dimethylformamide into a 100 mL reaction bottle at room temperature, add 0.83 g of terephthalic acid and 1.215 g of Anhydrous ferric chloride, after it was completely dissolved, reacted in an oil bath at 100 °C for 12 h. After the reaction, centrifuge at low speed (15 min, room temperature, 4000 rpm), remove the supernatant, repeat washing with ethanol, and centrifuge 3 times. The resulting product was vacuum-dried at 60 °C for 24 h to finally obtain Fe-MOF crystal powder;

[0032](2) Preparation of metal phosphide porous framework / graphene composite fiber: Add graphene oxide DMF solution and Fe-MOF crystal powder in sequence in a 5 mL centrifuge tube, and control the initial feeding ratio of each raw material as follows: graphene oxide Solution, concentration 6.7 mg / mL, graphene oxide sheet...

Embodiment 2

[0037] A preparation method of metal phosphide porous frame / graphene composite fiber, comprising the following steps:

[0038] (1) Preparation of Co-MOF crystal powder: Take a 50 mL beaker and add a mixed solution of 20 mL of methanol and 20 mL of ethanol, dissolve 725 mg of cobalt nitrate hexahydrate in the mixed solution, and stir until completely dissolved. Add a mixed solution of 20 mL of methanol and 20 mL of ethanol to another 50 mL beaker, dissolve 821 mg of 2-methylimidazole in the mixed solution, and stir until completely dissolved. The solutions in the above two beakers were mixed and stirred evenly, and reacted at room temperature for 24 h. After the reaction, centrifuge (15 min, room temperature, 4000 rpm), remove the supernatant, and wash with methanol three times. After the product is vacuum-dried at 60 °C for 24 h, the Co-MOF crystal powder is finally obtained;

[0039] (2) Preparation of metal phosphide porous framework / graphene composite fiber: add graphene o...

Embodiment 3

[0042] The preparation method of metal phosphide porous framework / graphene composite fiber comprises the following steps: adding graphene oxide DMF solution, Fe-MOF crystal powder and Co-MOF crystal powder in sequence in a centrifuge tube of 5 mL size, controlling the concentration of each raw material The initial feeding ratio is as follows: graphene oxide solution, concentration 6.7 mg / mL, graphene oxide sheet lateral size is 50 μm; Fe-MOF crystal powder 15 mg, Co-MOF crystal powder 15 mg, graphene oxide, Fe-MOF crystal The mass ratio of powder and Co-MOF crystal powder is 4:3:3; the obtained mixture is continuously mixed by magnetic stirring for 2 min under airtight conditions to obtain a composite gel, which is the spinning solution, and the spinning solution is further wet-spun Silk, specifically: the spinning solution is continuously injected into an ethyl acetate coagulation bath through a syringe, then vacuum filtered, and dried naturally to obtain a fibrous precursor; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Charge and discharge specific capacity | aaaaa | aaaaa |

| Charge and discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com