A grinding-assisted laser cladding composite powder feeder

A composite powder and auxiliary laser technology, applied in metal material coating process, coating and other directions, can solve the problems of low efficiency, long cladding cycle, long time consumption, etc., to achieve the effect of flexible use and improved dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

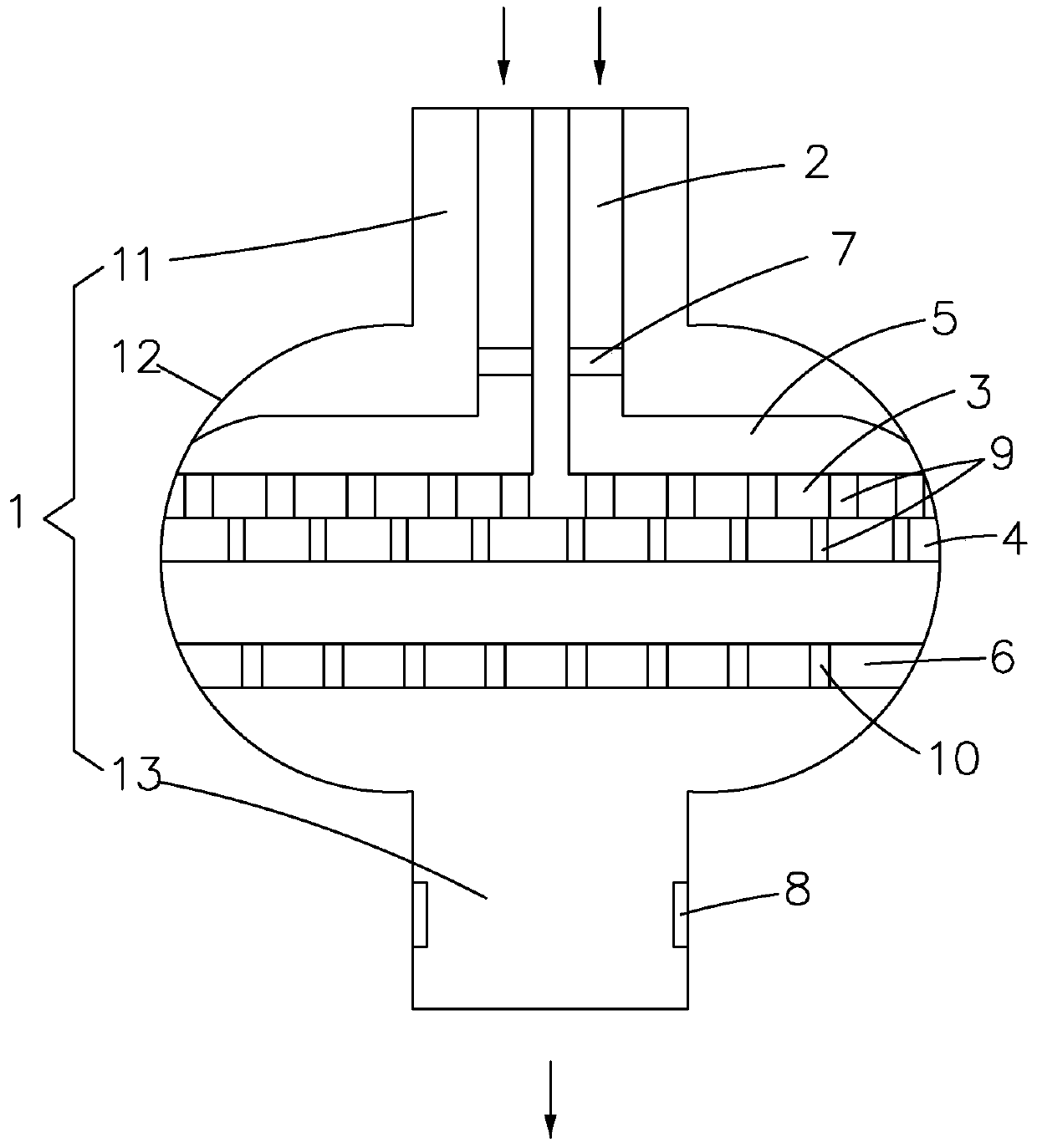

[0029] like figure 1 As shown, a grinding-assisted laser cladding composite powder powder feeder includes a box body 1, a powder feeding tube 2, a rotating upper plate 3, a grinding lower plate 4, an induction heating coil 5, an oscillator 6, a flow meter 7, a control The box 1 is divided into an upper opening 11, a middle section 12 and a lower opening 13. The upper opening 11 and the lower opening 13 are narrow and the volume of the middle section 12 is large. ; The powder feeding tube 2 is arranged inside the upper part of the upper opening 11 and the middle section 12, and the lower end of the powder feeding tube 2 is covered above the rotating upper plate 3; the rotating upper plate 3 And the grinding lower plate 4 is arranged in the middle section 12, and the grinding lower plate 4 is fixedly connected to the inner wall of the middle section 12, the rotating upper plate 3 acts on the grinding lower plate 4, and the rotating upper plate 3 A plurality of through holes 9 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com