Film forming assembly, bearing assembly thereof and film forming method

A film-forming method and component technology, which is applied in the field of film-forming, film-forming components and their carrying components, can solve problems such as disadvantages, poor versatility of mask plates, and reduce film-forming shadow effects, so as to improve versatility and reduce shadow effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

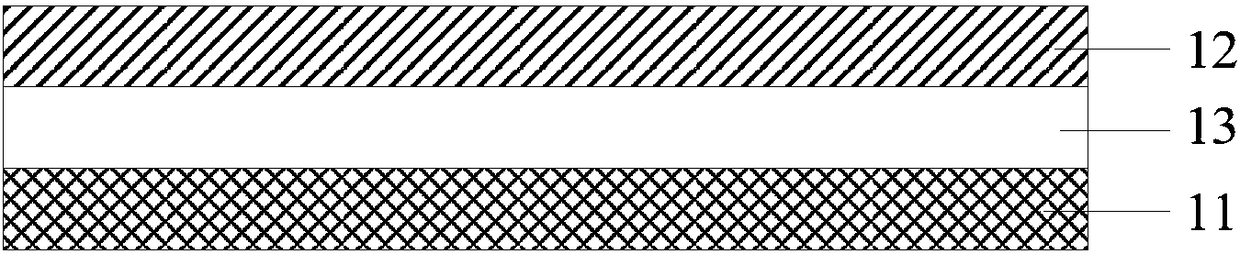

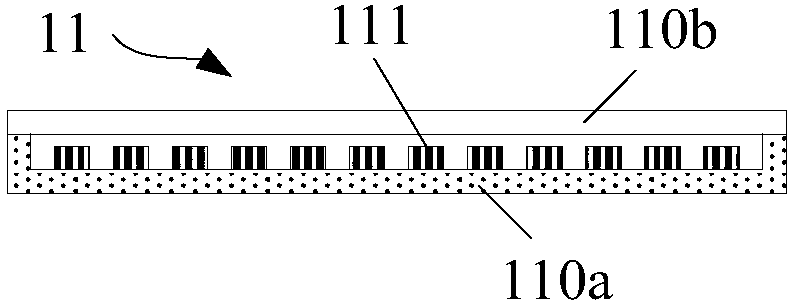

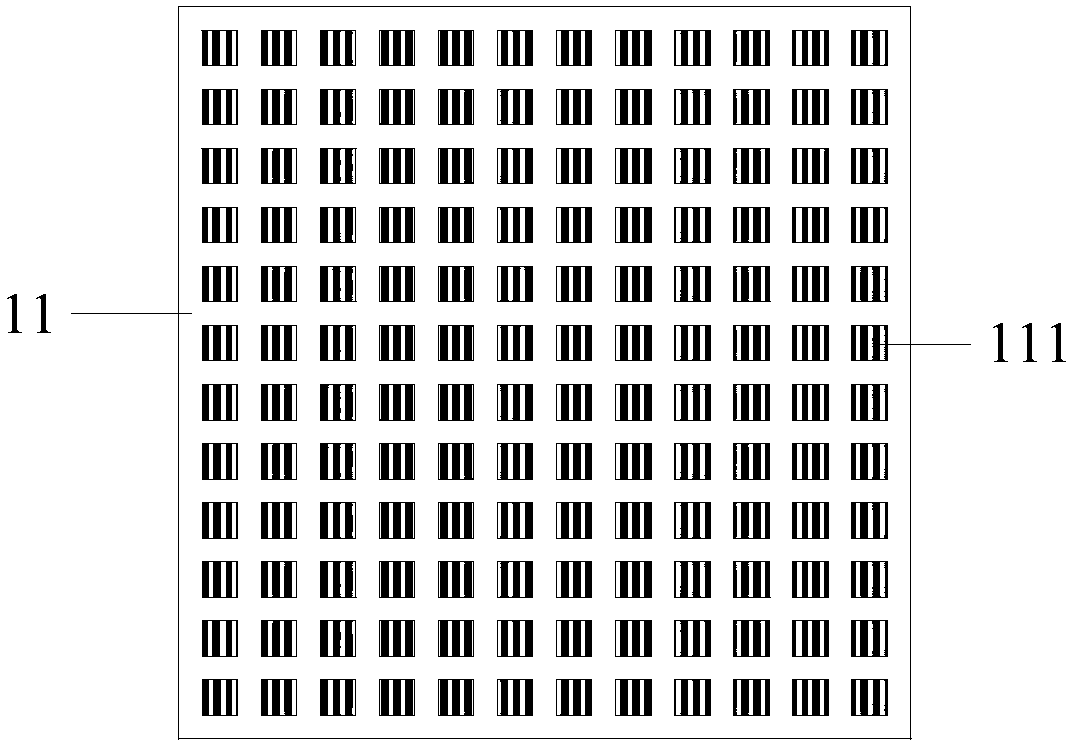

[0025] The main purpose of this application is: the stage is provided with a plurality of magnetic parts, and each magnetic part is movably connected or detachably connected with the stage. The arrangement of the magnetic parts on the stage is used to adjust the magnetic field distribution above the stage, so that the mask plate is evenly distributed magnetic force, so that the mask plate can be as close as possible to the substrate to be filmed, minimizing the The distance from the substrate to be filmed is small, so the present application is beneficial to improve the versatility of the carrier to the mask plate type and reduce the shadow effect.

[0026] This application can be used to vapor-deposit preset patterns on various types of substrates to be film-formed, such as vapor-depositing OLEDs (Organic Light Emitting Diode, organic electroluminescent diodes) in sub-pixel regions of display panels. Moreover, the film forming methods include but are not limited to CVD (Chemi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com