Flat cable automatic gluing machine

An automatic and gluing machine technology, which is applied in the field of gluing machines, can solve the problems of uneven gluing thickness, low work efficiency, and inability to apply wiring, etc., and achieve the effect of improving versatility and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

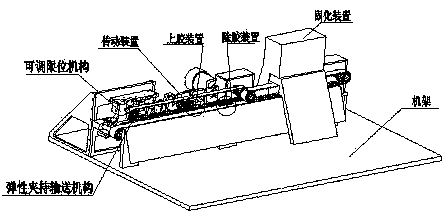

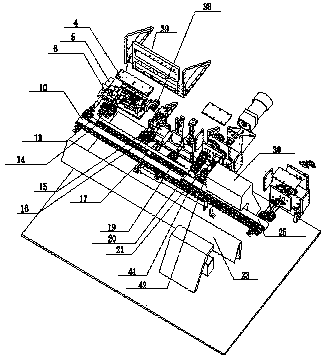

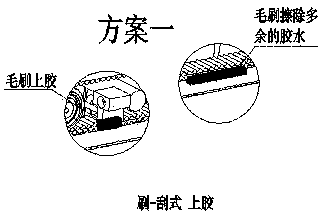

[0026] The invention provides an embodiment of an automatic gluing machine for arranging wires, which includes a frame, a transmission device, a gluing device, a degluing device and a curing device. The devices are sequentially arranged on the transmission device, and the end of the transmission device close to the gluing device is provided with an adjustable limit mechanism, and the transmission device includes an elastic clamping and conveying mechanism. The adjustable limit mechanism includes a scale plate 4, a fixed plate 39, a limit sheet metal 5 and a pressure fine-tuning screw 38. The scale plate is parallel to the elastic clamping and conveying mechanism, and the fixed plate 39 and the limit sheet metal 5 are vertically arranged on the scale plate 4. sides. The elastic clamping conveying mechanism comprises an upper pressure tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com