Modifier applied to high-strength asphalt concrete as well as preparation and application thereof

A technology of asphalt concrete and modifier, applied in the field of asphalt concrete, which can solve the problems of unfavorable safety production, complex preparation process, and the need for organic solvents, and achieve the effects of facilitating stress transfer, large adsorption capacity, and improving high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

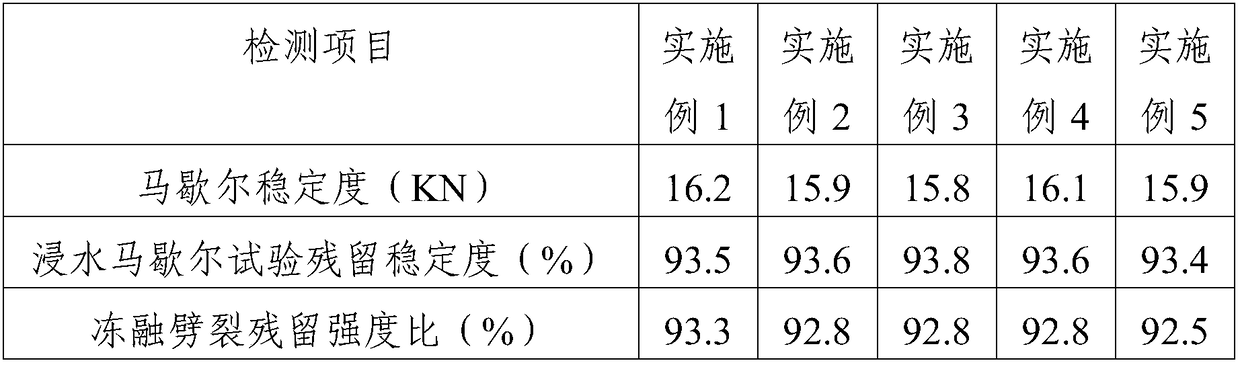

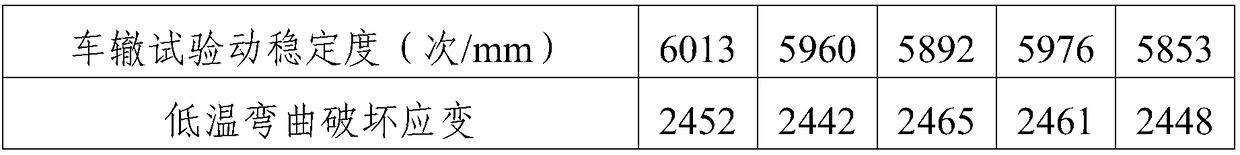

Examples

Embodiment 1

[0023] A modifier for high-strength asphalt concrete, which consists of component A and component B, wherein the mass ratio of component A to component B is 1:0.17;

[0024] Component A is composed of the following raw materials in parts by weight: water-based epoxy resin emulsion 92.8%, silane coupling agent modified nano-alumina 3.7%, hollow mesoporous silica microspheres 3.3%, silane coupling agent KH560 0.2% .

[0025] Among them, the water-based epoxy resin emulsion is AB-EP-20 from Zhejiang Anbang.

[0026] Component B is composed of the following raw materials in weight percentage: tetraethylenepentamine 80%, deionized water 20%.

[0027] The preparation method of the modifier for the above-mentioned high-strength asphalt concrete comprises the following steps:

[0028] (1) Preparation of component A: Weigh water-based epoxy resin emulsion, nano-alumina, hollow mesoporous silica microspheres, and silane coupling agent KH560 according to the formula ratio, and then tra...

Embodiment 2

[0032] A modifier for high-strength asphalt concrete, consisting of component A and component B, wherein the mass ratio of component A to component B is 1:0.3;

[0033] Component A is composed of the following raw materials in parts by weight: water-based epoxy resin emulsion 96%, nano-alumina 2%, hollow mesoporous silica microspheres 1.9%, silane coupling agent KH560 0.1%;

[0034] Among them, the water-based epoxy resin emulsion is AB-EP-20 from Zhejiang Anbang.

[0035] Component B is composed of the following raw materials in weight percentage: 85% of diethylenetriamine, 15% of deionized water.

[0036] The preparation method of the modifier for the above-mentioned high-strength asphalt concrete comprises the following steps:

[0037] (1) Preparation of component A: Weigh water-based epoxy resin emulsion, nano-alumina, hollow mesoporous silica microspheres, and silane coupling agent KH560 according to the formula ratio, and then transfer the above-mentioned raw materials ...

Embodiment 3

[0041] A modifier for high-strength asphalt concrete, consisting of component A and component B, wherein the mass ratio of component A to component B is 1:0.1;

[0042] Component A is composed of the following raw materials in parts by weight: water-based epoxy resin emulsion 90%, nano-alumina 4.8%, hollow mesoporous silica microspheres 5%, silane coupling agent KH550 0.2%;

[0043] Wherein, the water-based epoxy resin emulsion is or 3520-WY-55 of Hexion Chemical Co., Ltd.

[0044] Component B is composed of the following raw materials in weight percentage: 70% of triethylenetetramine and 30% of deionized water.

[0045] The preparation method of the above-mentioned modifier for high-strength asphalt concrete is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com