Paper folding structure capable of conducting self-folding based on electric drive

An origami structure and self-folding technology are applied in the field of flexible robots to achieve the effects of reduced complexity, convenient processing and simple overall method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

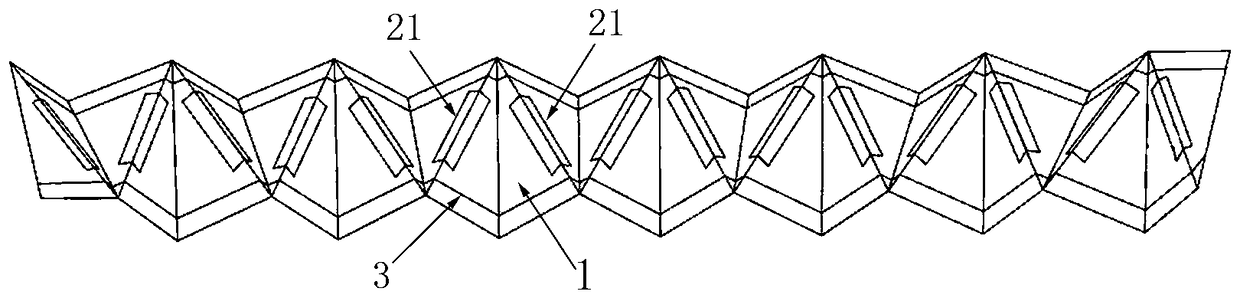

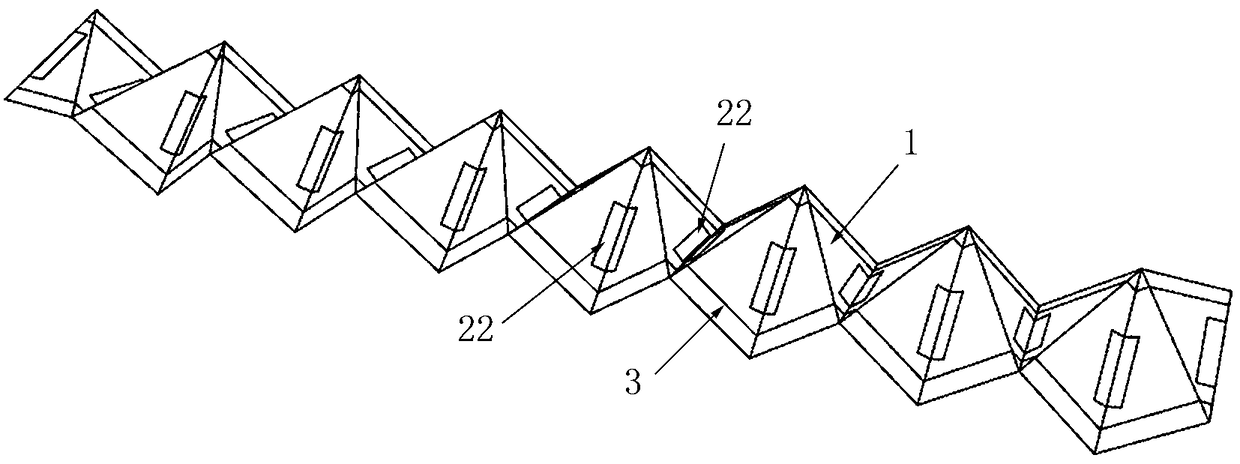

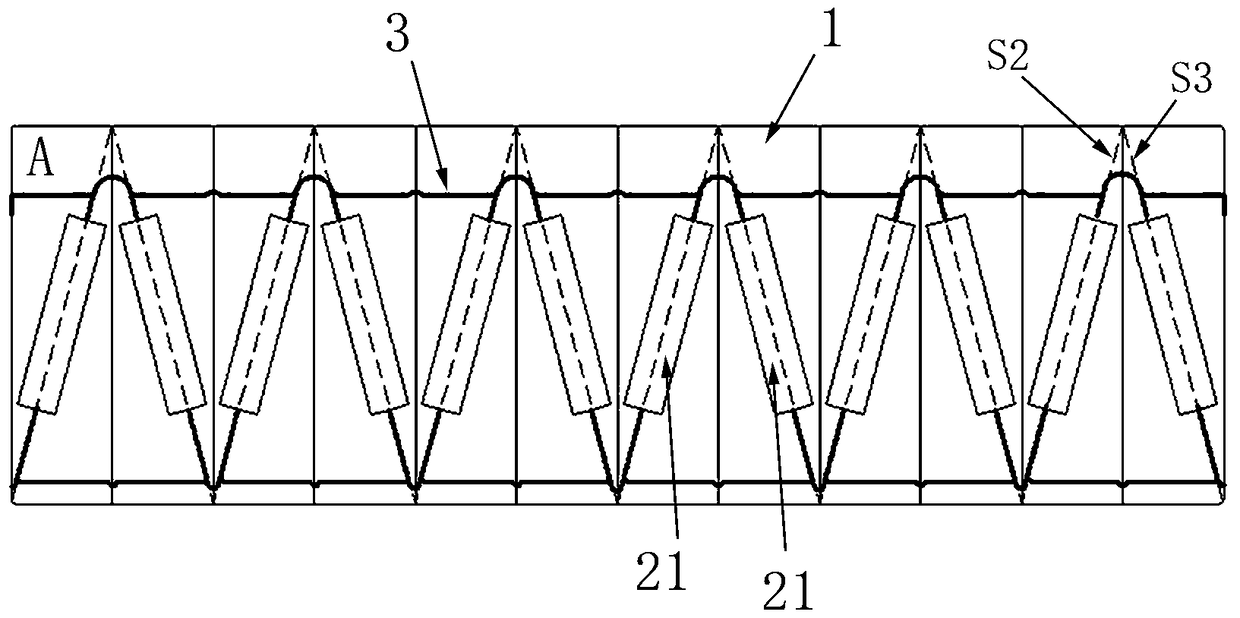

[0022] See attached picture. The origami structure described in this embodiment is formed by arranging and combining several rectangular units 1. The rectangular units are sheet structures on both sides of AB (front and back). The rectangular units are left and right symmetrical with the center line S1 as the boundary. The trace includes the central line S1 and the intersecting diagonal lines S2\S3 on the left and right sides. The diagonal lines S2\S3 on both sides form an isosceles triangle with the bottom of the rectangular unit, and the center line is exactly the height on the bottom. The boundary line S4 between two adjacent rectangular units is also a crease;

[0023] The AB faces of the rectangular unit are provided with memory alloy patches 2, and the first memory alloy patches 21 on the A surface are fixed on the diagonals on the left and right sides, located in the middle of the diagonals, and on the same rectangular unit. The first memory alloy patch on the front is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com