Partially-decoupled two-freedom-degree parallel mechanism

A degree of freedom, partial solution technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as restricting applications, restricting the working space of the moving platform, and restricting the rotation range of the mechanism, achieving simple structure, stable operation, and flexibility. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

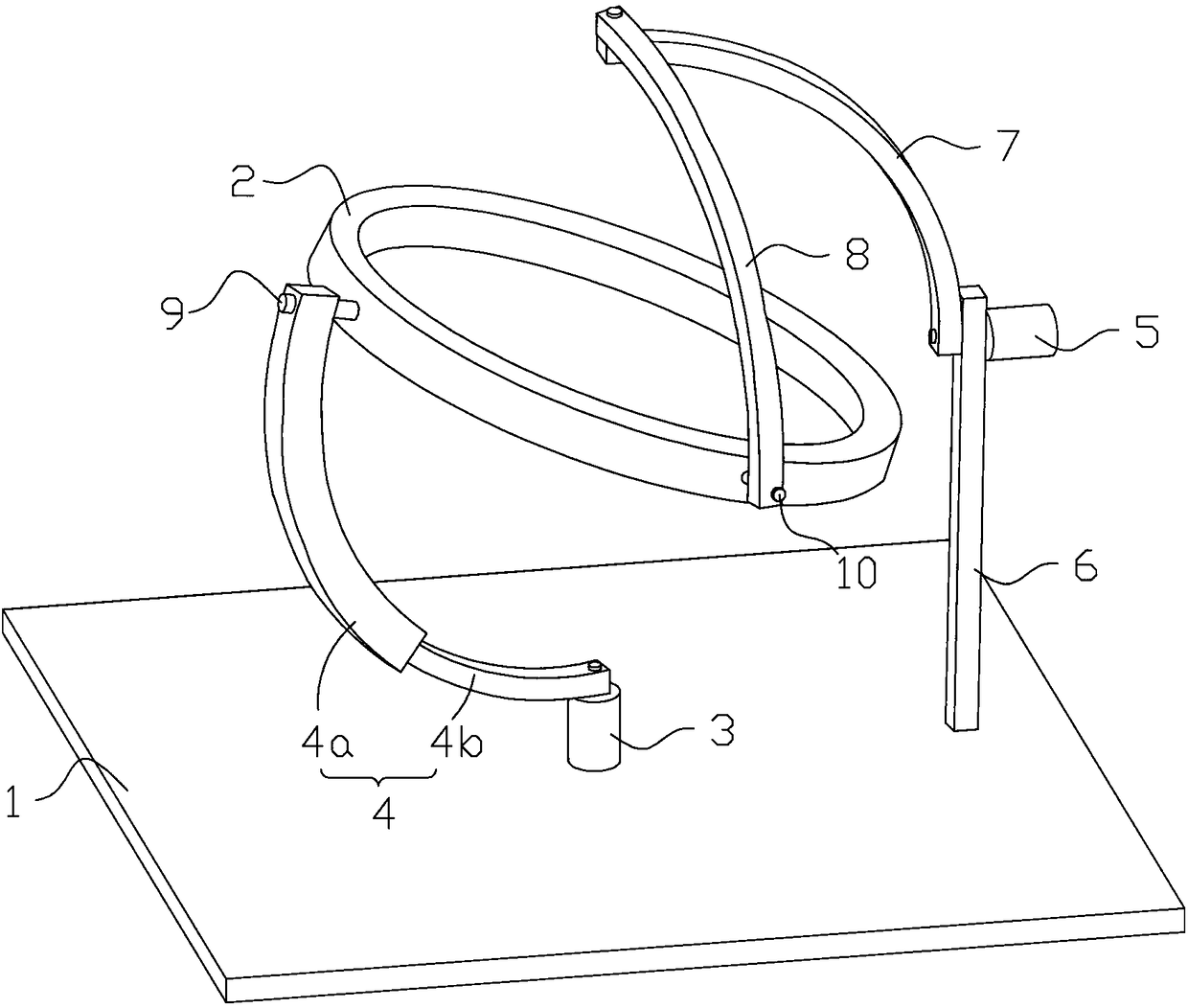

[0033] see figure 1 , a partially decoupled two-degree-of-freedom parallel mechanism, including a static platform 1, a dynamic platform 2, and a first kinematic branch chain and a second kinematic branch chain respectively connected between the static platform 1 and the dynamic platform 2;

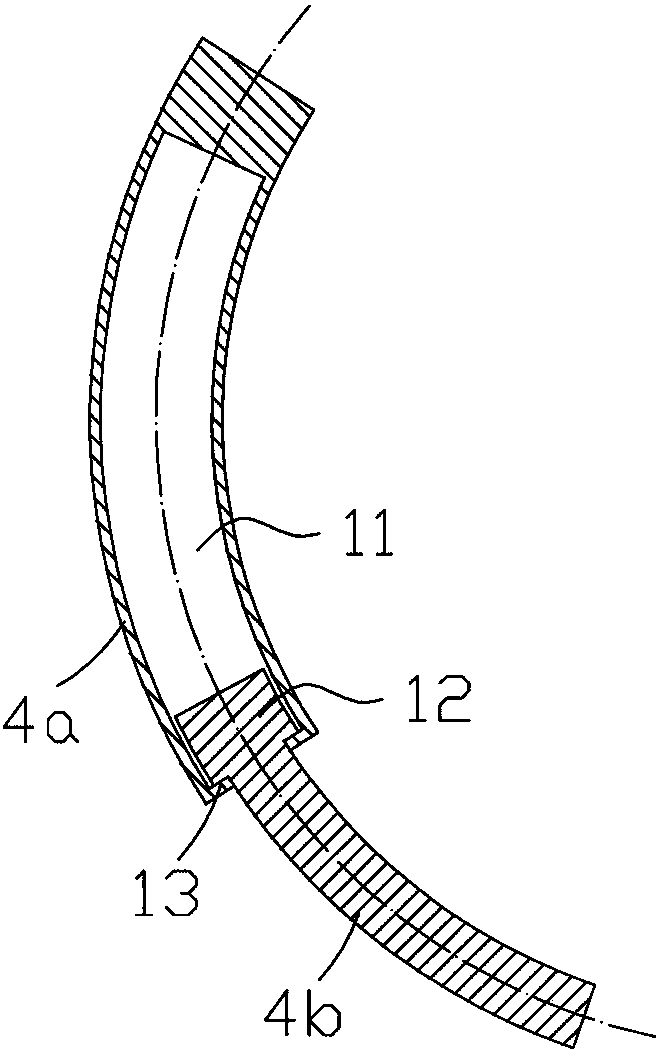

[0034] The first kinematic branch chain includes a first rotating pair 3, and the static platform 1 is rotationally connected to one end of the first arc-shaped connecting rod 4 through the first rotating pair 3, wherein the first arc-shaped connecting rod 4 is composed of two The first arc-shaped rod 4a arranged at the center of the arc and the second arc-shaped rod 4b are connected as a whole in a relatively sliding connection;

[0035] The second kinematic branch chain includes a second rotating pair 5, and a bracket 6 is provided on the static platform 1. The bracket 6 is rotationally connected with one end of the second arc connecting rod 7 through the second rotating pair 5, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com