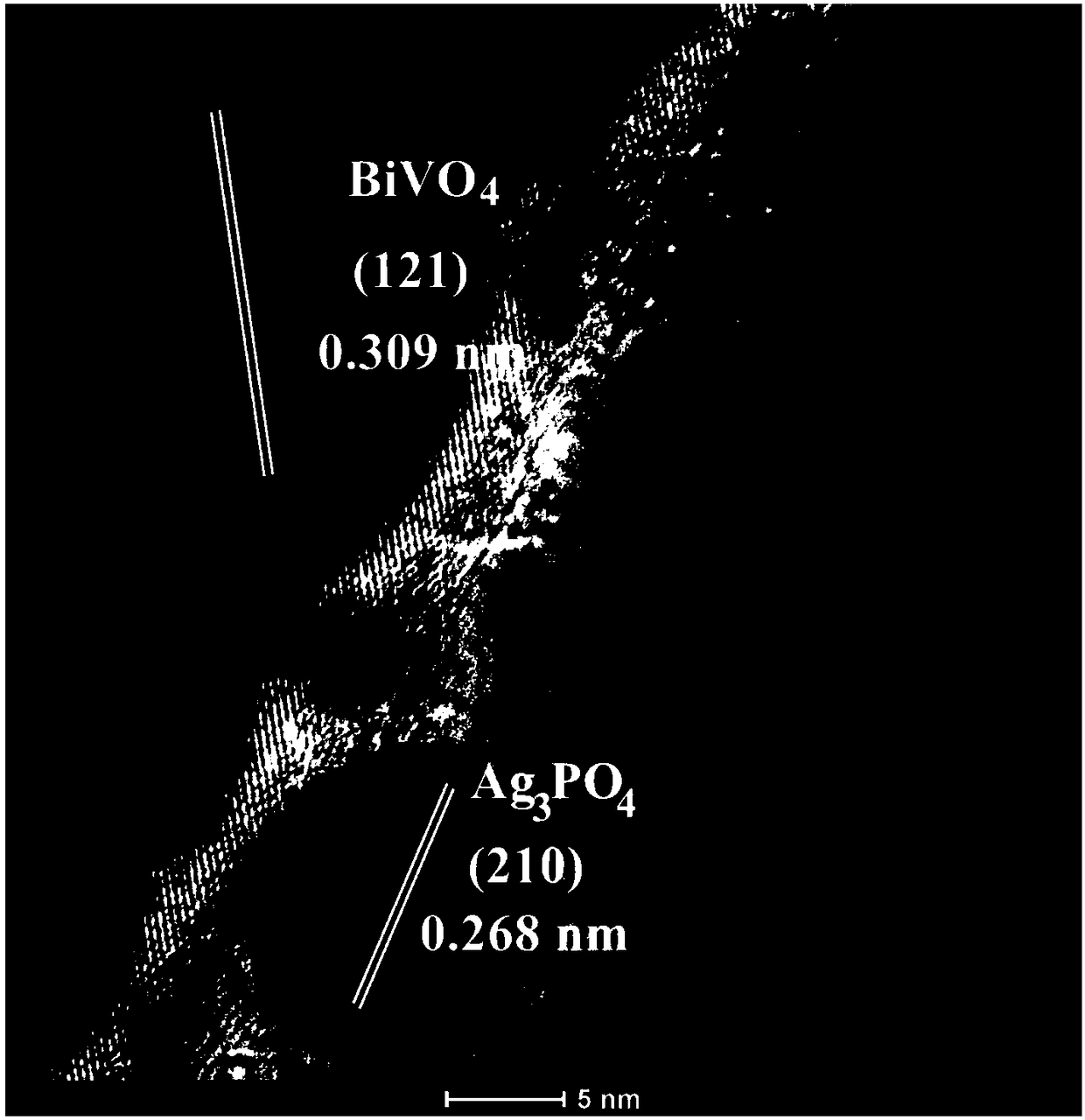

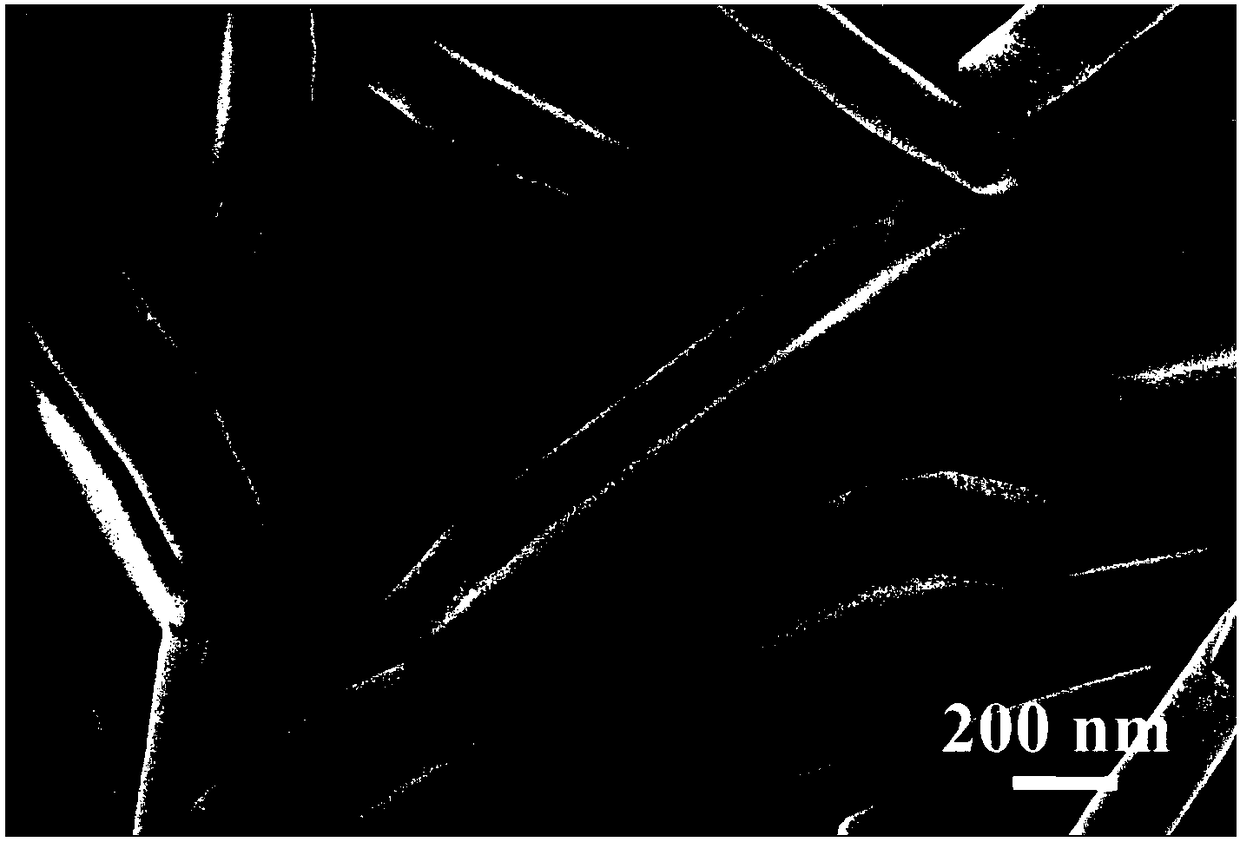

Production method of BiVO4/Ag3PO4 film for photoelectrocatalytic water decomposition

A photoelectric catalysis, thin film technology, applied in chemical instruments and methods, electrolysis process, electrolysis components, etc., can solve the problems of easy compounding, slow surface water oxidation kinetics, etc., achieve broad application prospects, improve photoelectric conversion efficiency, start The effect of low potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1) Dissolve 0.395 g of bismuth nitrate and 0.438 g of ethylenediaminetetraacetic acid in 15ml of water, adjust the pH of the solution to 10 with concentrated ammonia water, stir until a colorless and transparent solution is formed, and weigh 0.117 g of ammonium metavanadate and 0.141 g of ethylenediaminetetraacetic acid were dissolved in 15 ml of water, and the pH of the solution was adjusted to 10 with concentrated ammonia water, and stirred until a yellow transparent solution was formed. The two solutions were mixed and stirred evenly to prepare a bismuth vanadate seed layer precursor;

[0041] 2) Spin-coat the bismuth vanadate precursor solution on the FTO conductive glass, heat-treat at 500°C for 15 minutes after each spin-coating, spin-coat 3 times, 10 drops each time, and then heat-treat at 500°C for 1 hour to obtain vanadium bismuth acid seed layer;

[0042] 3) Dissolve 0.12 g of bismuth nitrate and 0.132 g of ethylenediaminetetraacetic acid in 30 ml of water, adju...

Embodiment 2

[0051] 1) Dissolve 0.395 g of bismuth nitrate and 0.438 g of ethylenediaminetetraacetic acid in 15ml of water, adjust the pH of the solution to 10 with concentrated ammonia water, stir until a colorless and transparent solution is formed, and weigh 0.117 g of ammonium metavanadate and 0.141 g of ethylenediaminetetraacetic acid were dissolved in 15 ml of water, and the pH of the solution was adjusted to 10 with concentrated ammonia water, and stirred until a yellow transparent solution was formed. The two solutions were mixed and stirred evenly to prepare a bismuth vanadate seed layer precursor;

[0052] 2) Spin-coat the bismuth vanadate precursor solution on the FTO conductive glass, heat-treat at 500°C for 15 minutes after each spin-coating, spin-coat 3 times, 10 drops each time, and then heat-treat at 500°C for 1 hour to obtain vanadium bismuth acid seed layer;

[0053] 3) Dissolve 0.12 g of bismuth nitrate and 0.132 g of ethylenediaminetetraacetic acid in 30 ml of water, ad...

Embodiment 3

[0060] 1) Dissolve 0.395 g of bismuth nitrate and 0.438 g of ethylenediaminetetraacetic acid in 15ml of water, adjust the pH of the solution to 10 with concentrated ammonia water, stir until a colorless and transparent solution is formed, and weigh 0.117 g of ammonium metavanadate and 0.141 g of ethylenediaminetetraacetic acid were dissolved in 15 ml of water, and the pH of the solution was adjusted to 10 with concentrated ammonia water, and stirred until a yellow transparent solution was formed. The two solutions were mixed and stirred evenly to prepare a bismuth vanadate seed layer precursor;

[0061] 2) Spin-coat the bismuth vanadate precursor solution on the FTO conductive glass, heat-treat at 500°C for 15 minutes after each spin-coating, spin-coat 3 times, 10 drops each time, and then heat-treat at 500°C for 1 hour to obtain vanadium bismuth acid seed layer;

[0062] 3) Dissolve 0.12 g of bismuth nitrate and 0.132 g of ethylenediaminetetraacetic acid in 30 ml of water, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com