Treatment method and treatment equipment for dry tail gas in artificial board industry

A technology for drying exhaust gas and treatment method, which is applied in separation methods, multi-stage water treatment, chemical instruments and methods, etc., can solve the problems of high humidity of exhaust gas, large water consumption, and high operating costs, so as to reduce operating costs and reduce water consumption. The amount of dosage, the effect of long operating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiment of the present invention will be described in detail below in conjunction with accompanying drawing:

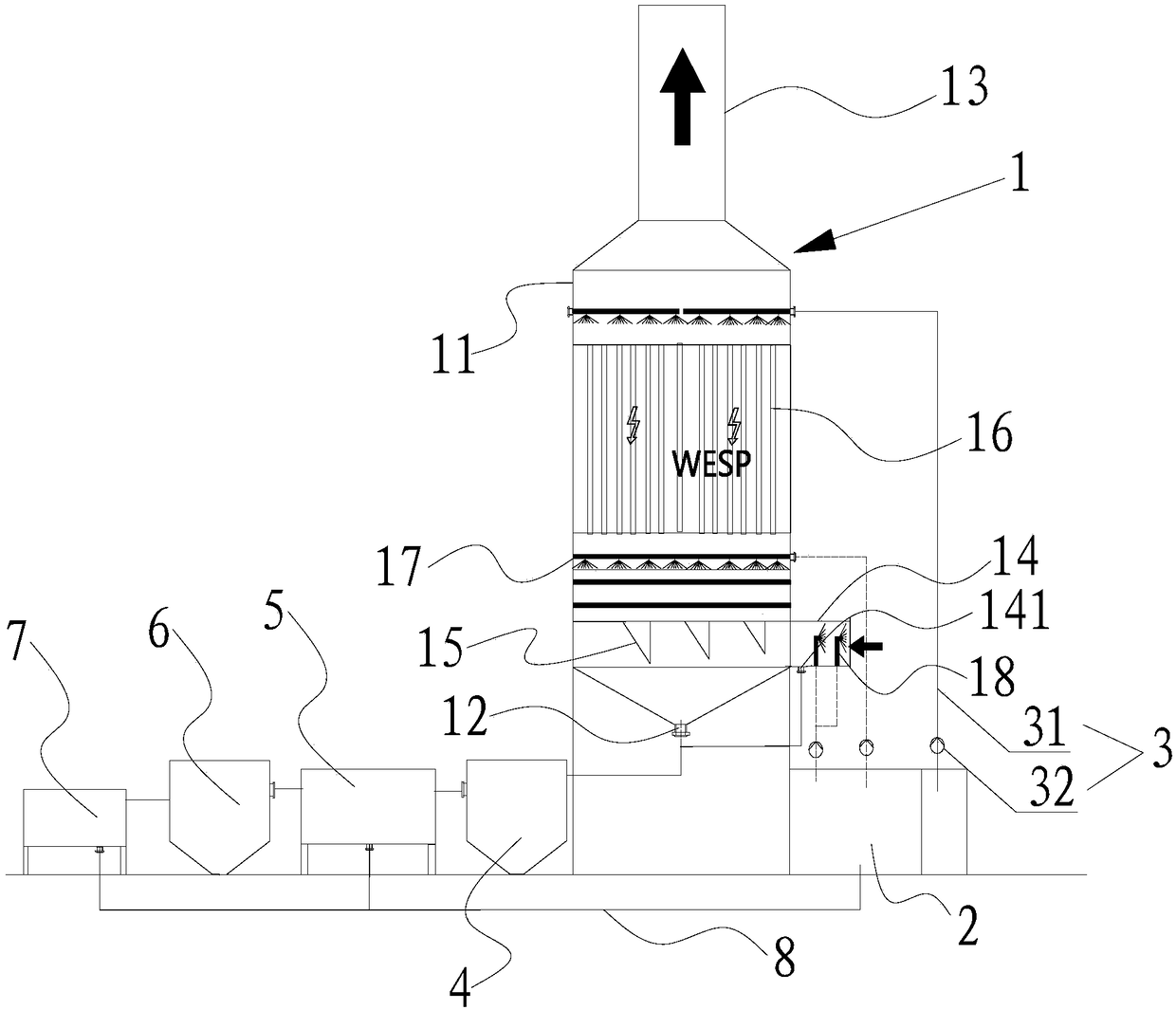

[0026] Such as figure 1 The dry tail gas treatment equipment in the wood-based panel industry shown mainly includes a spray dust removal component 1, a circulation tank 2, a first sedimentation tank 4, a filter component 5, a second sedimentation tank 6, and the like.

[0027] Wherein, the spray dedusting assembly 1 comprises a tower body 11, an exhaust pipe 13, an air guide pipe 14, a wet electrostatic precipitator 16, a pre-sprayer 18, etc.; the bottom of the tower body 11 is a cone and forms a water outlet 12, The spray water in it is derived; the exhaust pipe 13 is arranged on the top of the tower body 11 and communicated with it, and is used to discharge the treated tail gas; It communicates with the tower body 11 and is used to introduce the dry tail gas of the wood-based panel industry to be processed into the tower body 11; The wet el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com