Preparation method of CO2 responsive intelligent hydrophilic and hydrophobic switching copper net

A hydrophilic-hydrophobic, CO2 technology, applied in the field of preparation of hydrophilic-hydrophobic conversion materials, can solve the problems of inability to improve hydrophobicity and superhydrophobicity, and achieve the effects of fast hydrophilic-hydrophobic conversion speed, improved durability, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

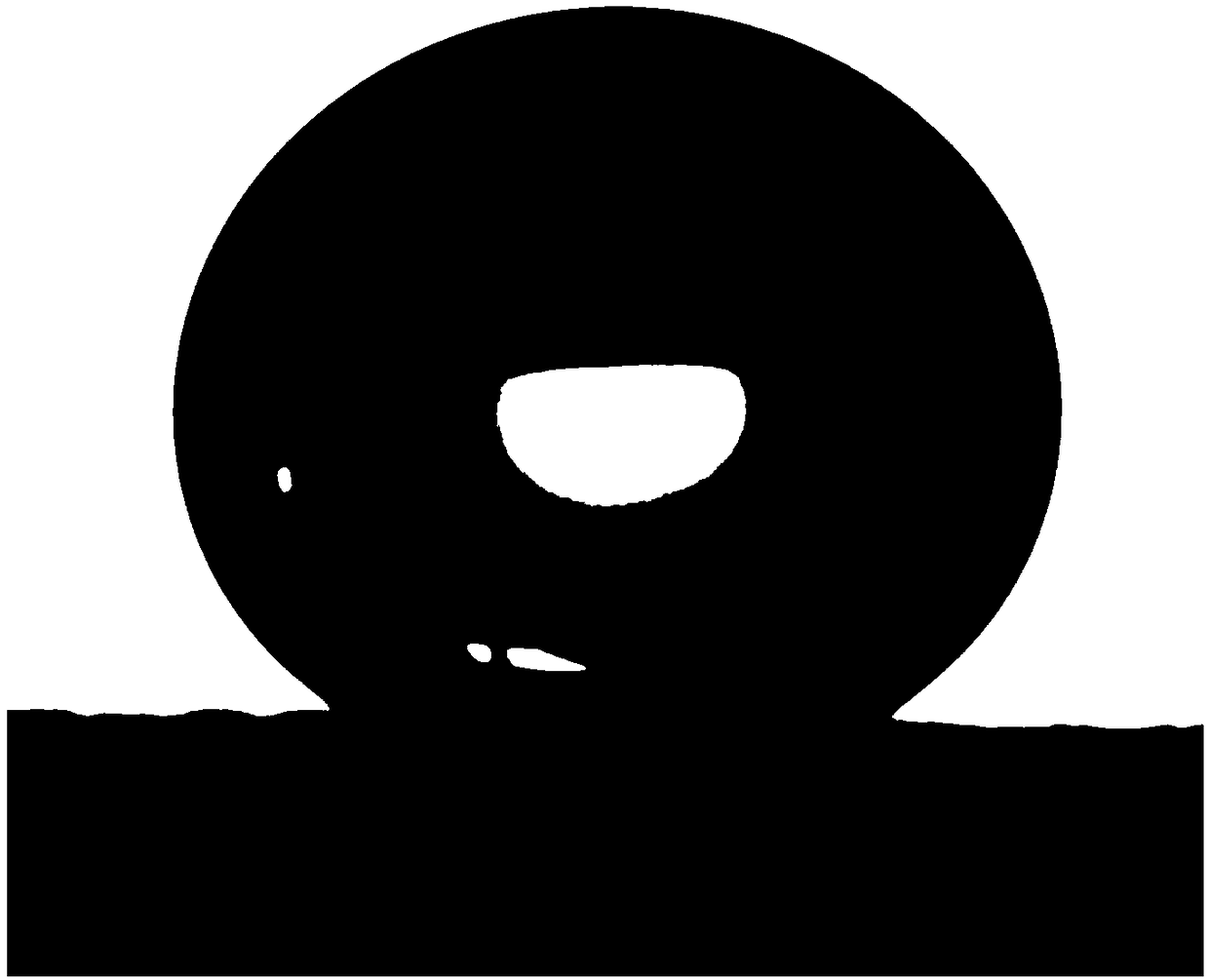

Image

Examples

specific Embodiment approach 1

[0026] Specific implementation mode 1: This implementation mode is a CO 2 The preparation method of responsive intelligent hydrophilic-hydrophobic conversion copper mesh is specifically carried out according to the following steps:

[0027] 1. Preparation of a copper mesh with a needle-like rough structure: Place the copper mesh with a pore size of 50 μm to 1000 μm in acetone, ethanol and ultrapure water for 15 minutes to 30 minutes, and the ultrasonic frequency is 25KHz to 60KHz. Dry at a temperature of 40°C to 80°C for 30 minutes;

[0028] Prepare NaOH and K 2 S 2 o 8 The mixed aqueous solution, put the dried copper mesh in NaOH and K 2 S 2 o 8in a mixed aqueous solution, and etched at room temperature for 10min to 120min, then cleaned with ultrapure water, and dried for 30min at a temperature of 40°C to 80°C to obtain a copper mesh with a needle-like rough structure;

[0029] NaOH and K described in step 1 2 S 2 o 8 The concentration of NaOH in the mixed aqueous s...

specific Embodiment approach 2

[0038] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the inert gas I described in step 3 is N 2 . Others are the same as the first embodiment.

specific Embodiment approach 3

[0039] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that the inert gas I described in step 3 is argon. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com