Metal gasket

A technology of metal gaskets and gaskets, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problem of damaging the sealing function, and achieve the effect of low reaction force and excellent sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

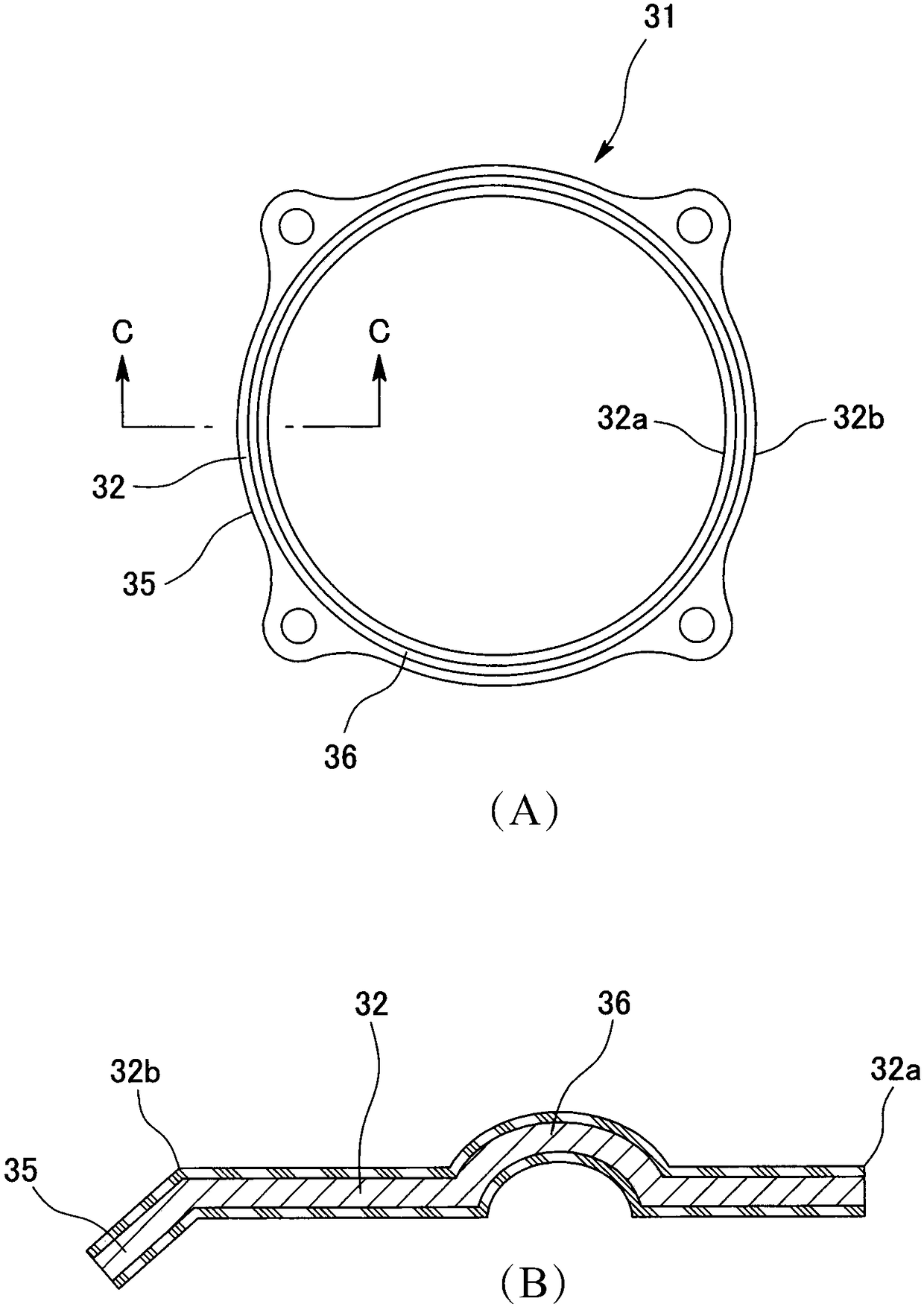

[0034] Hereinafter, embodiments of the present invention will be described based on the drawings.

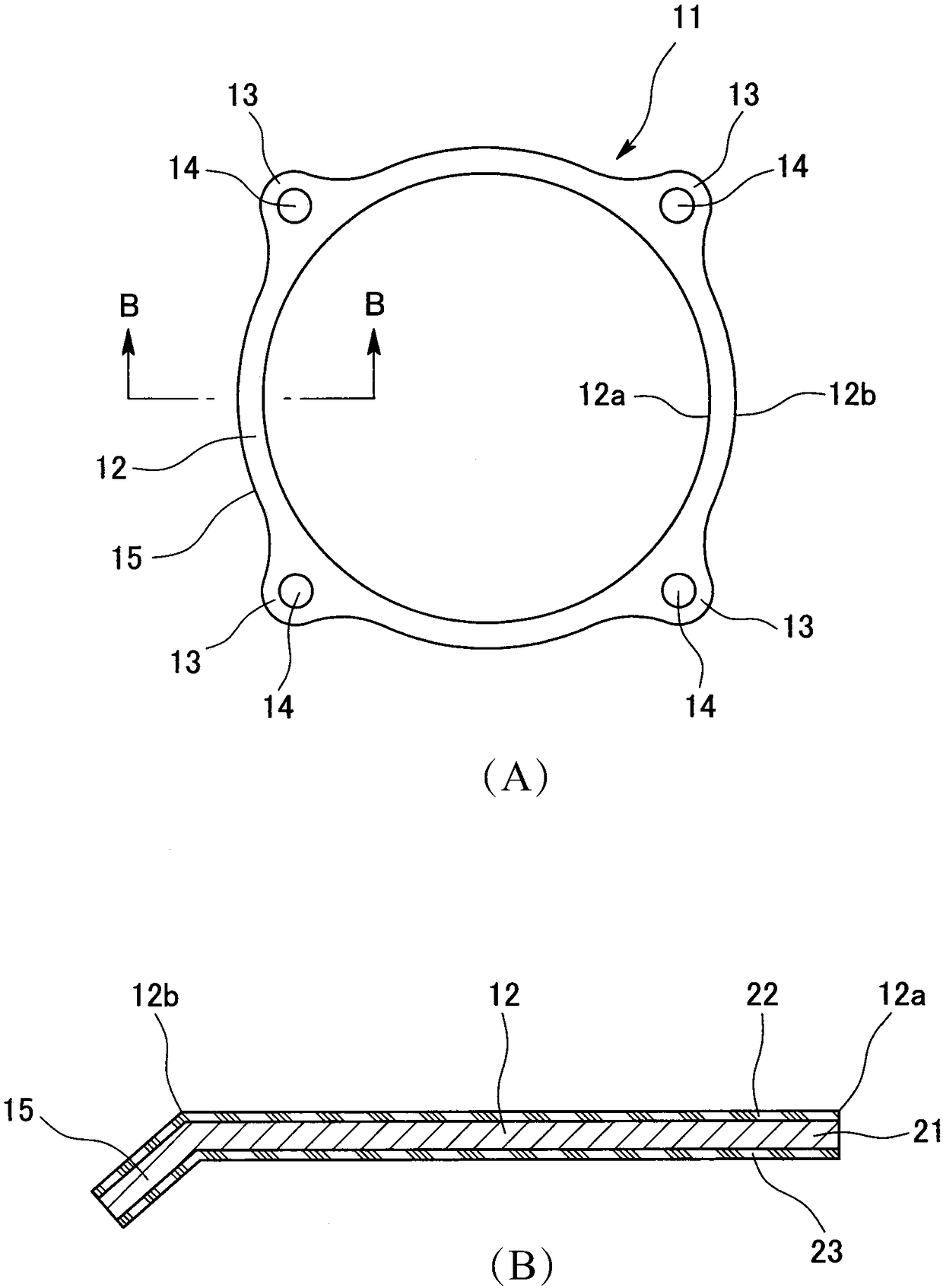

[0035] figure 1 (A) and (B) show the metal gasket 11 according to the embodiment of the present invention. The metal gasket 11 according to this embodiment is a circular flat metal gasket formed in a ring shape. In addition, the metal gasket 11 is sandwiched between a pair of frames (housing, not shown, refer to Figure 5 or Figure 6 ) between the gaskets, as its function, to seal the internal space of the frame, and to seal external foreign matter such as salt water and deicing agent, thereby preventing external foreign matter from intruding into the gap between the frame and the gasket 11.

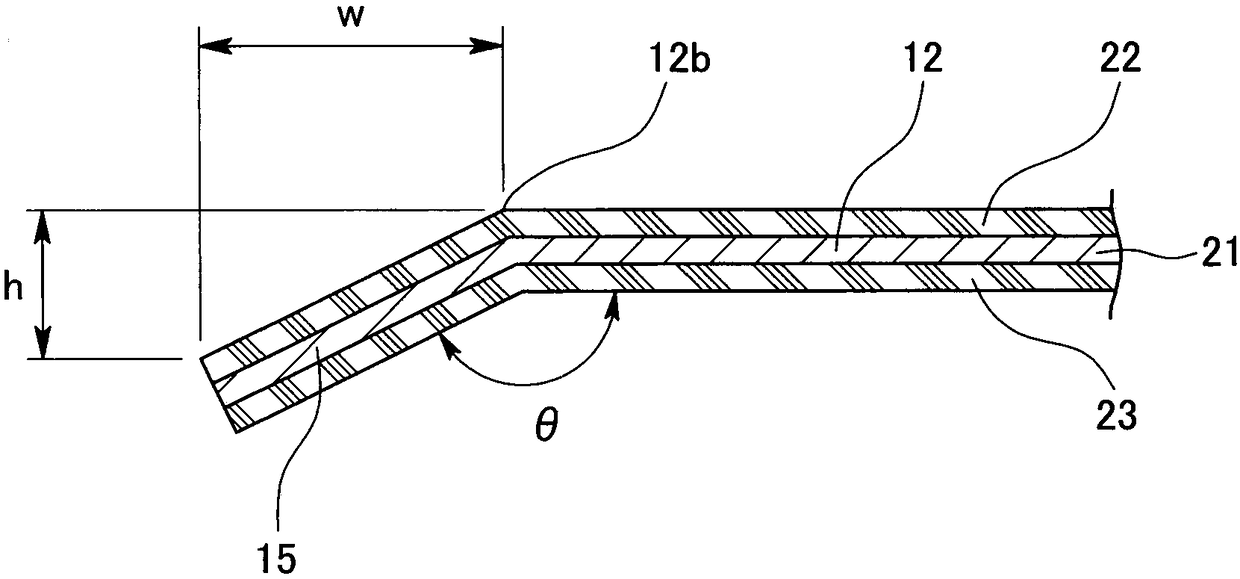

[0036] The metal gasket 11 has an annular linear portion 12 whose entire surface is planar from the inner peripheral portion 12a to the outer peripheral portion 12b. On the outer peripheral side of the linear portion 12, as a part of the linear portion 12, a plurality of jaws 13 (four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com