Multi-stage hydraulic machine continuously variable transmission for heavy vehicle

A continuously variable transmission, hydraulic machinery technology, applied in mechanical equipment, transmission parts, fluid transmission, etc., can solve the problems of increasing the complexity of the transmission mechanical structure, unable to achieve continuous transmission, and increasing costs, and achieve flexible shifting. Convenience, improved shifting range, and improved dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

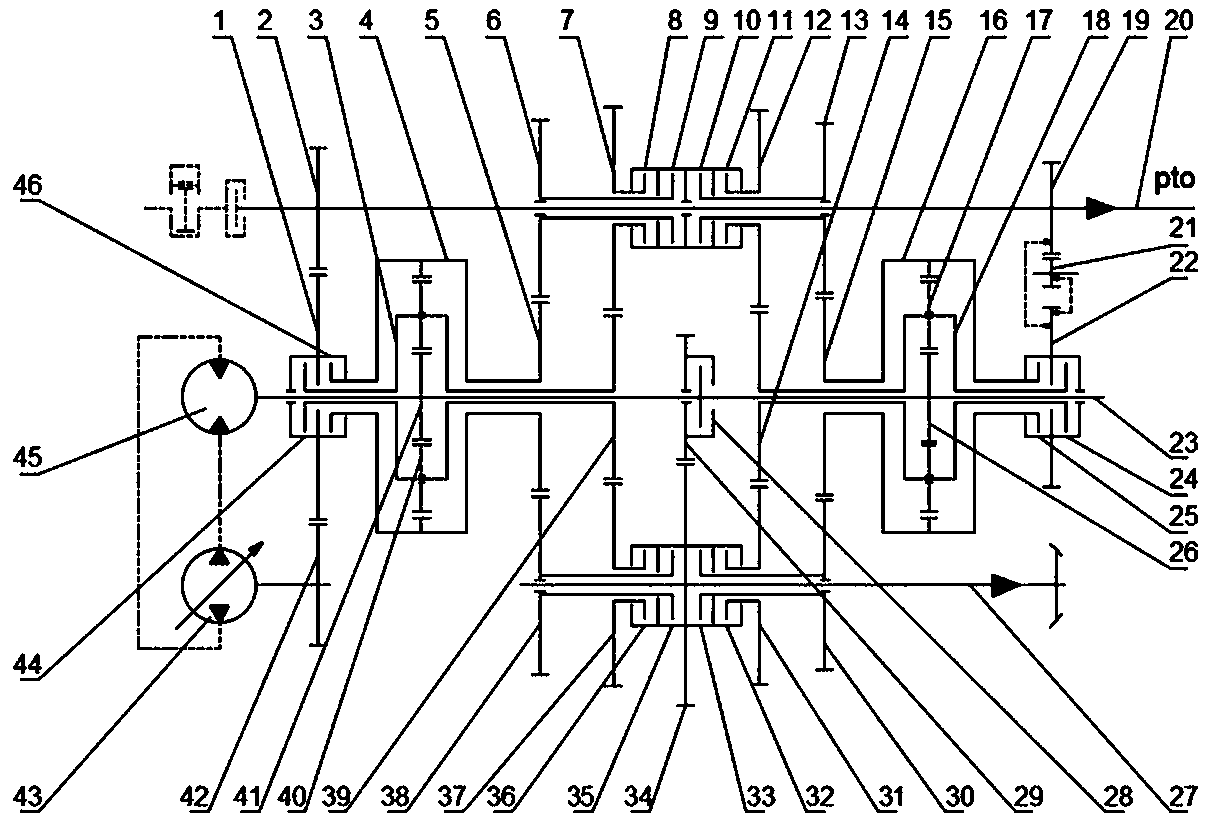

[0036] Embodiment 1, a kind of purely mechanical transmission form M2 gear of multi-stage hydraulic mechanical continuously variable transmission for heavy vehicles: as figure 2 As shown, the power transmitted from the engine realizes torque splitting at the first gear 2, and all the way is transmitted to the working device through the power shaft 20; all the way is transmitted to the third clutch housing through the second gear 1, and the front ring gear clutch 46 is engaged , the power is transmitted to the second clutch housing through the fifth gear 5 and the sixth gear 38 , the sixth gear clutch 35 is engaged, and finally the power is transmitted to the main output shaft 27 .

[0037] Similar to the M2 gear of the purely mechanical transmission form of the front planetary row, there is also the M1 gear; similarly, the purely mechanical transmission form of the rear planetary row has M3 gear and M4 gear, which will not be described in detail here. The present invention ha...

Embodiment 2

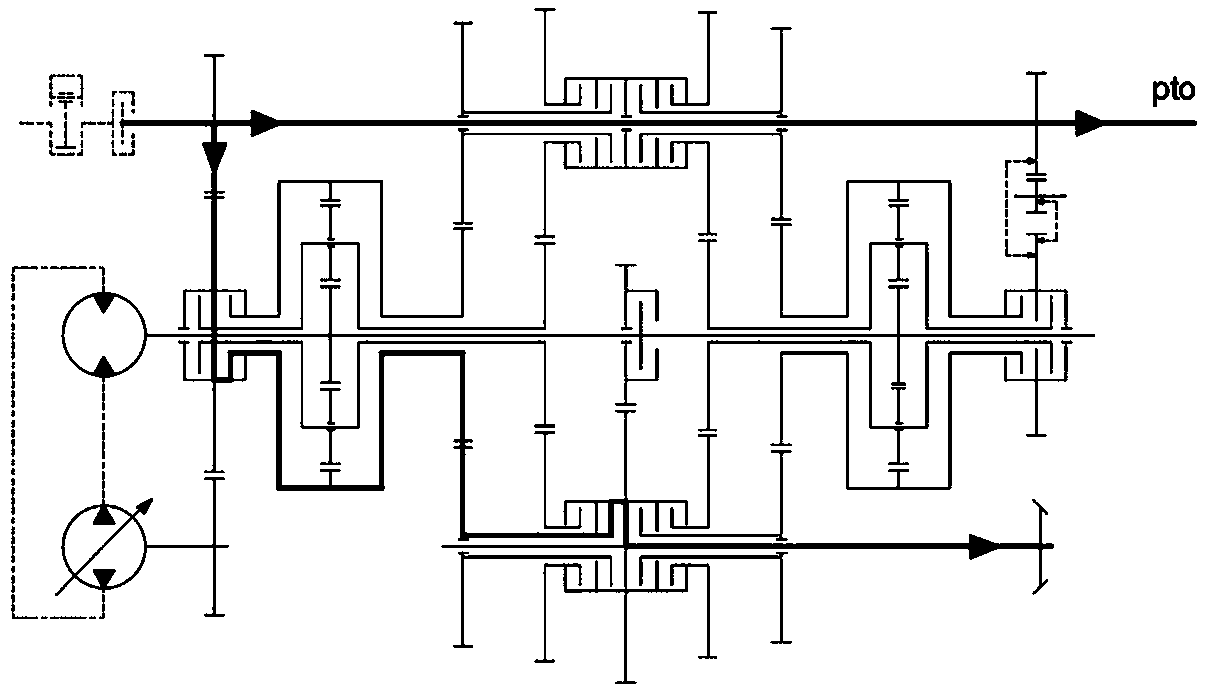

[0038] Embodiment 2. A multi-stage hydraulic-mechanical continuously variable transmission for heavy-duty vehicles is converging in the front planetary row converging device without passing through the output of the first clutch housing in the form of hydraulic-mechanical hybrid transmission HM2 gear: as image 3 As shown, the power transmitted from the engine realizes torque splitting at the first gear 2, and all the way is transmitted to the working device through the power shaft 20; all the way is transmitted to the third clutch housing through the second gear 1, and the front ring gear clutch 46 is engaged , the torque is divided again in the third clutch housing, one way is transmitted to the hydraulic circuit and transmitted to the front sun gear 41, and the other is transmitted to the front ring gear 4, and the power is realized at the front planetary row. 3 is transmitted to the eighth gear 39, the ninth gear 37, the ninth gear clutch 36 is engaged, and finally the powe...

Embodiment 3

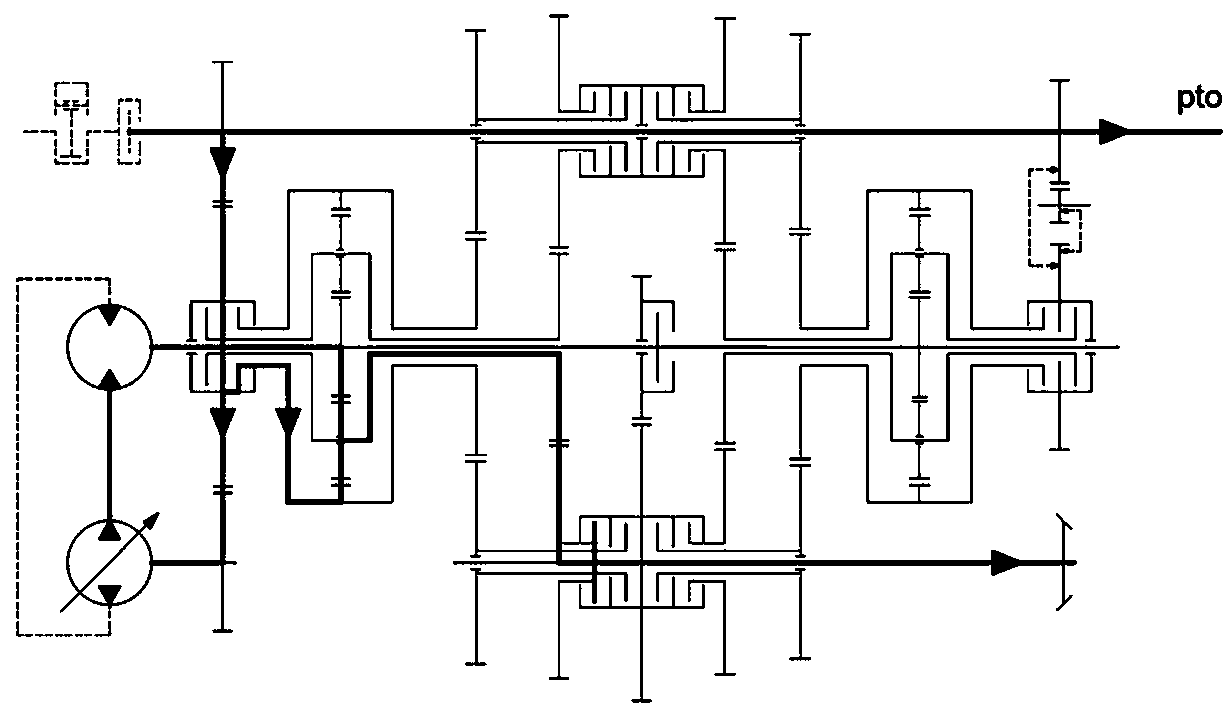

[0040] Embodiment 3. A multi-stage hydraulic-mechanical continuously variable transmission for heavy-duty vehicles in which the front planetary row confluences and passes through the first clutch housing to output the hydraulic-mechanical hybrid transmission form HM8 gear: as Figure 4 As shown, the power transmitted from the engine realizes torque splitting at the first gear 2, and all the way is transmitted to the working device through the power shaft 20; all the way is transmitted to the third clutch housing through the second gear 1, and the front ring gear clutch 46 is engaged , the torque is divided again in the third clutch housing, one way is transmitted to the front sun gear 41 through the hydraulic circuit, and the other is transmitted to the front ring gear 4, and the power is realized at the front planetary row. Transmission to the eighth gear 39, the seventh gear 7, the seventh gear clutch 8 and the twelfth gear clutch 11 are engaged, the power is transmitted to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com