Hydraulic bushing

A hydraulic bushing and sleeve technology, applied in the direction of shock absorbers, springs, spring/shock absorbers, etc., can solve the problems of increasing train operating costs, wear of wheels and tracks, etc., and achieve the effect of maintaining stable operation and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing.

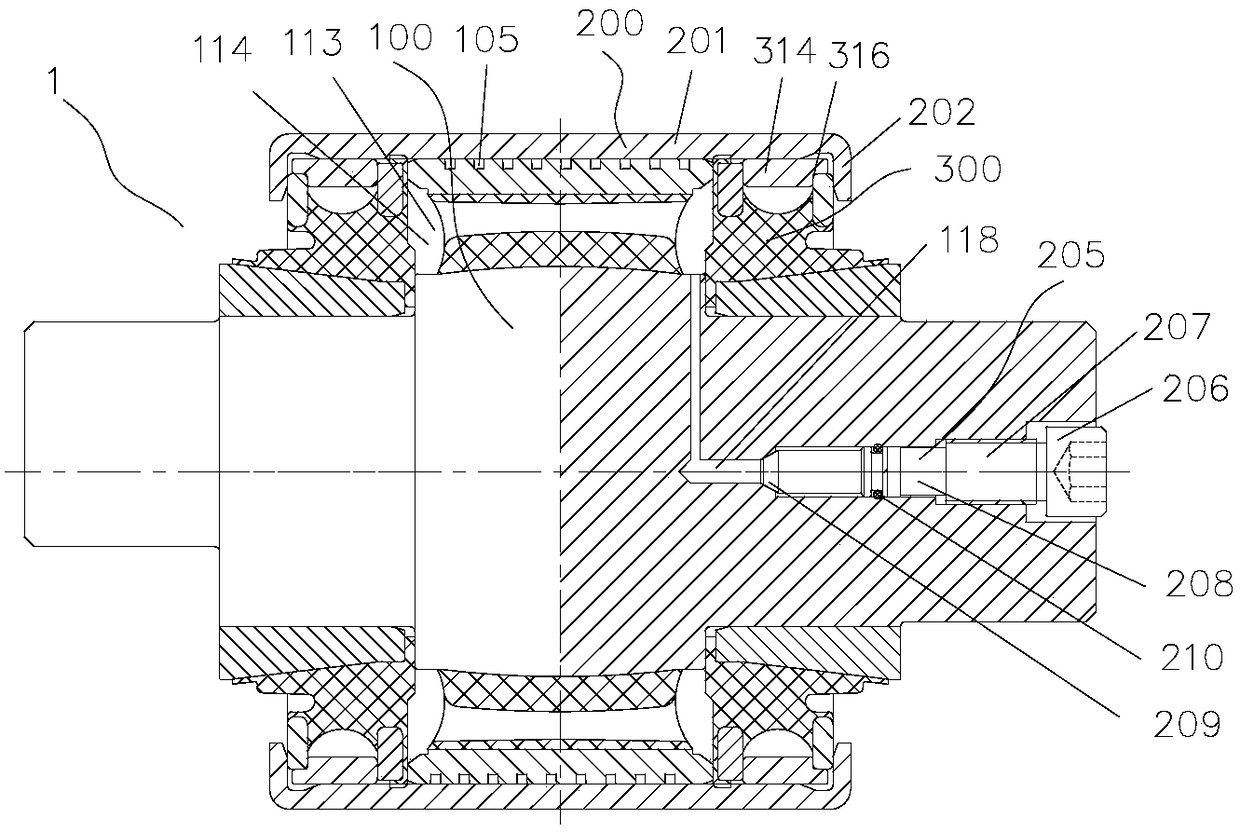

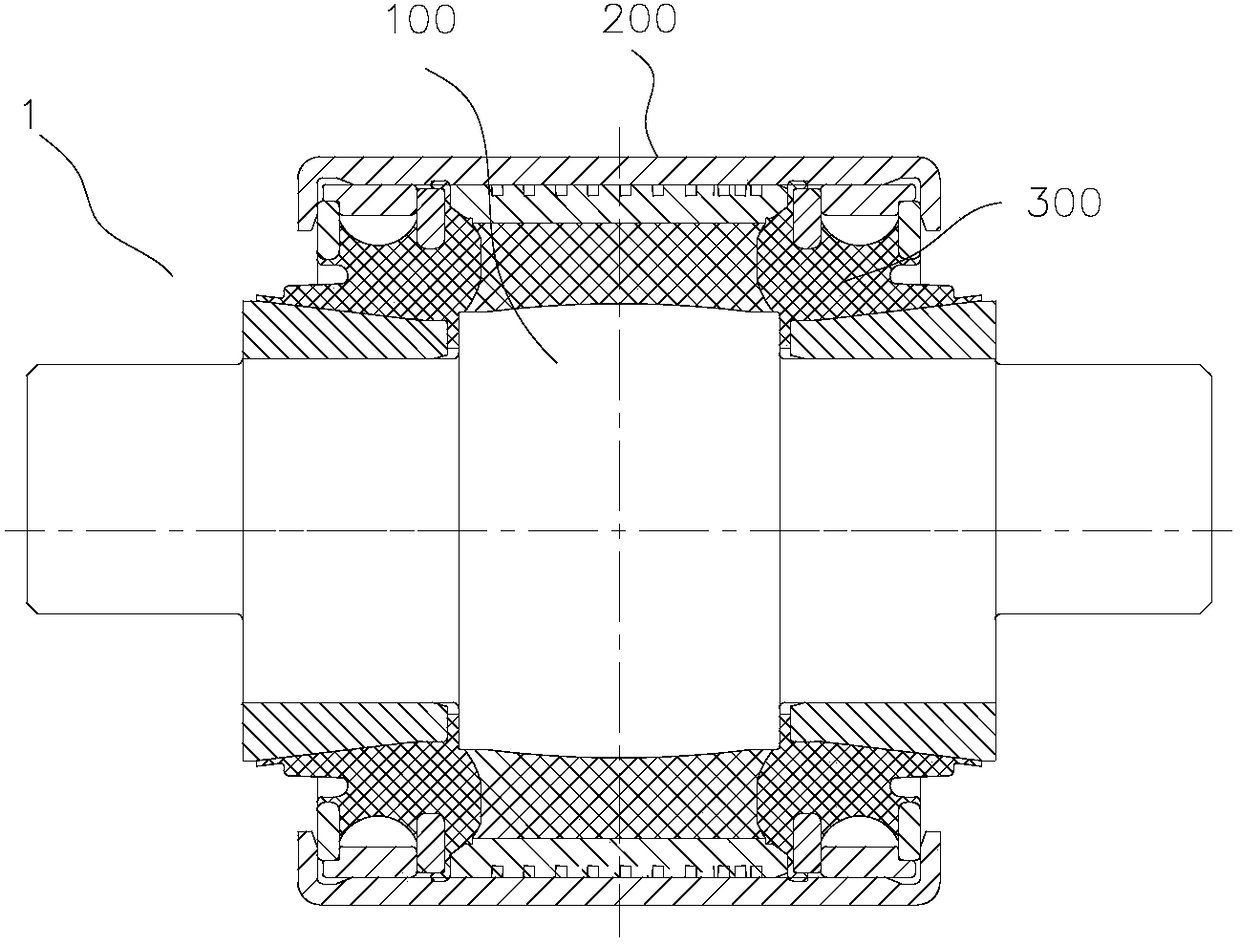

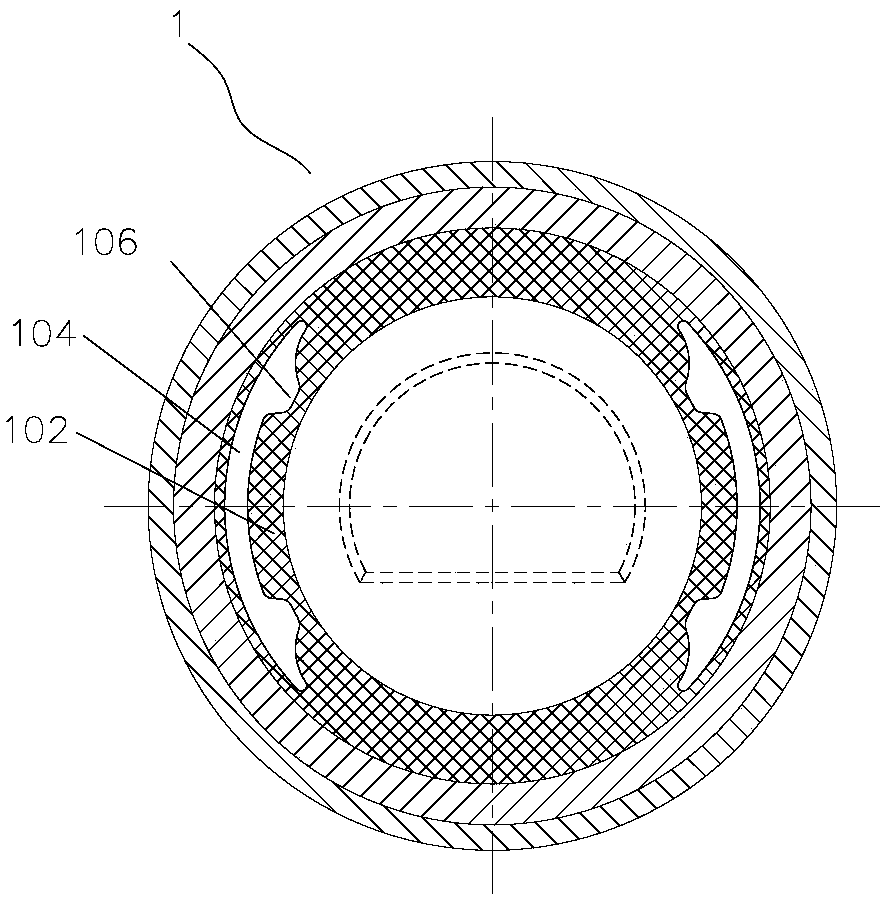

[0036] like Figure 1-3 As shown, the hydraulic bushing 1 includes a main spring 100 and a cylindrical casing 200 . like Figure 4-6 As shown, the main spring 100 has a mandrel 101 , a first rubber body 102 and a sleeve 103 . The first rubber body 102 is sheathed on the outer wall of the mandrel 101 . Two liquid chambers 104 are provided on the first rubber body 102 . In addition, in the radial direction of the first rubber body 102, two liquid cavities 104 are oppositely distributed at intervals. The sleeve 103 is sheathed on the outer wall of the first rubber body 102 . Meanwhile, a groove 110 is provided on the wall of the sleeve 103 . Wherein, the main spring 100 is disposed in the inner cavity of the casing 200 , so that the casing 200 and the sleeve 103 form a first flow channel 105 at the groove 110 for communicating with the two liquid chambers 104 .

[0037]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com