Artificial board surface defect online detection device based on synchronous principle

A detection device, wood-based panel technology, applied in measurement devices, conveyor control devices, transportation and packaging, etc., can solve the problems of large amount of calculation, blurred image motion, affecting the reliability of image processing, etc. Image motion blur, the effect of precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

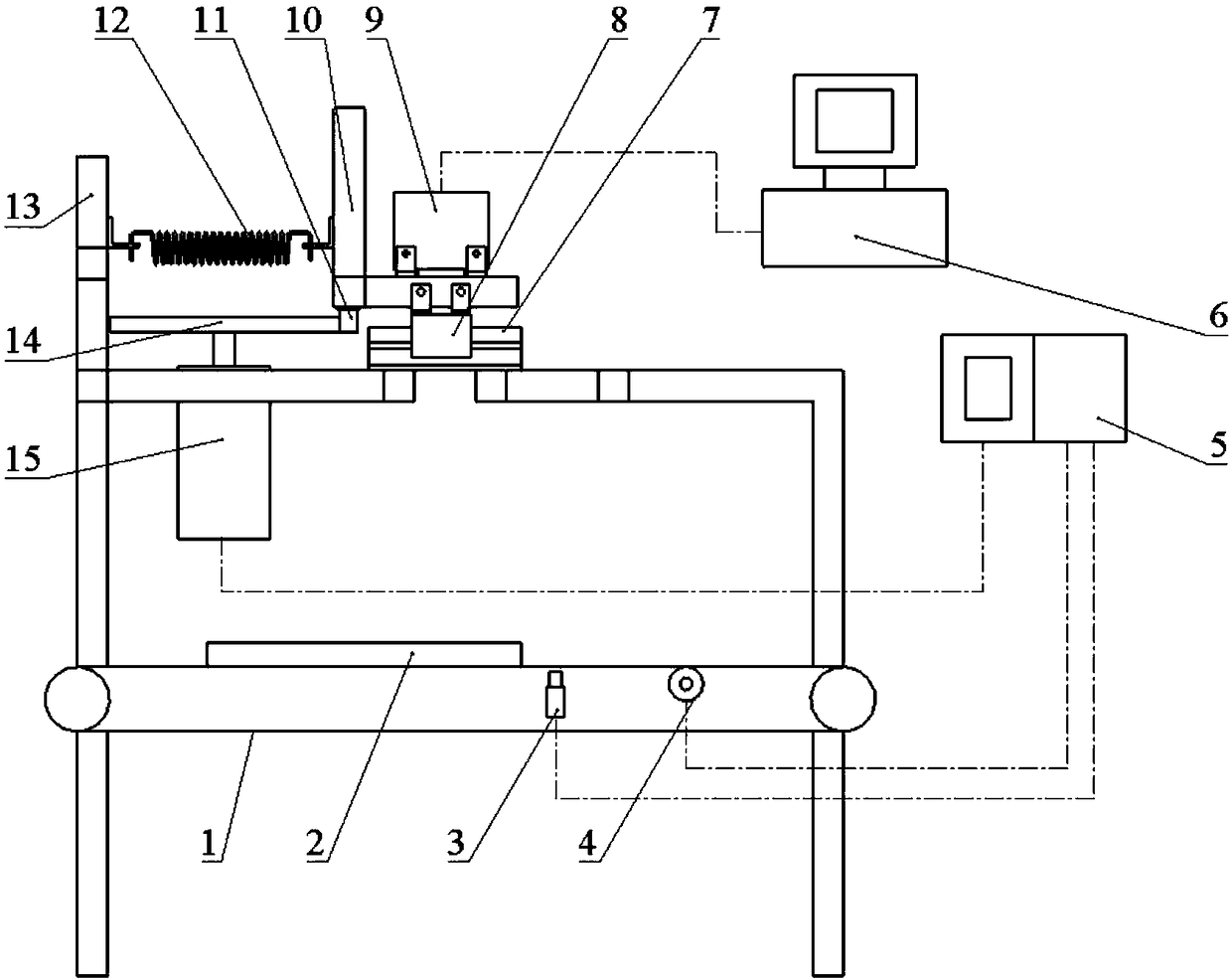

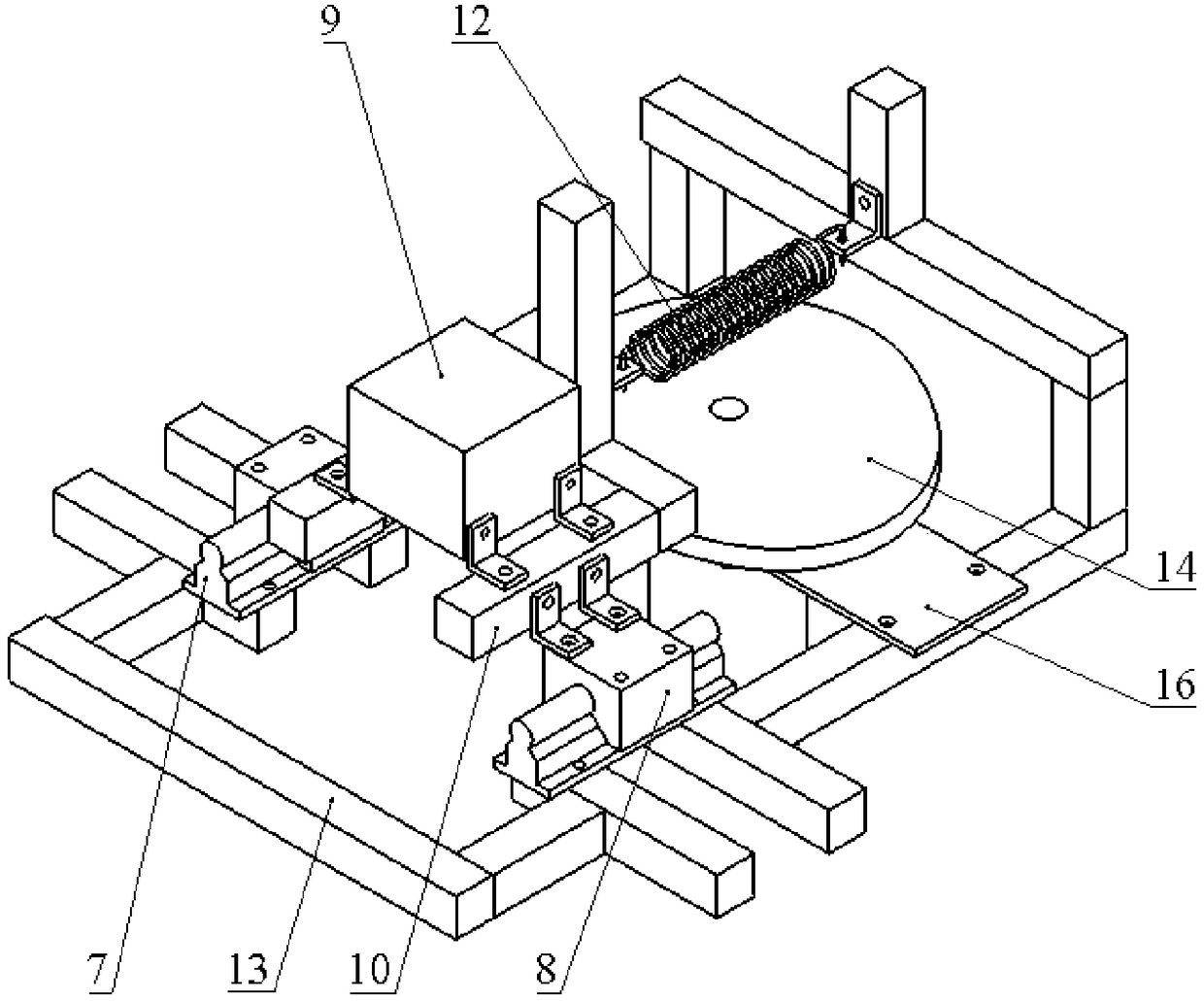

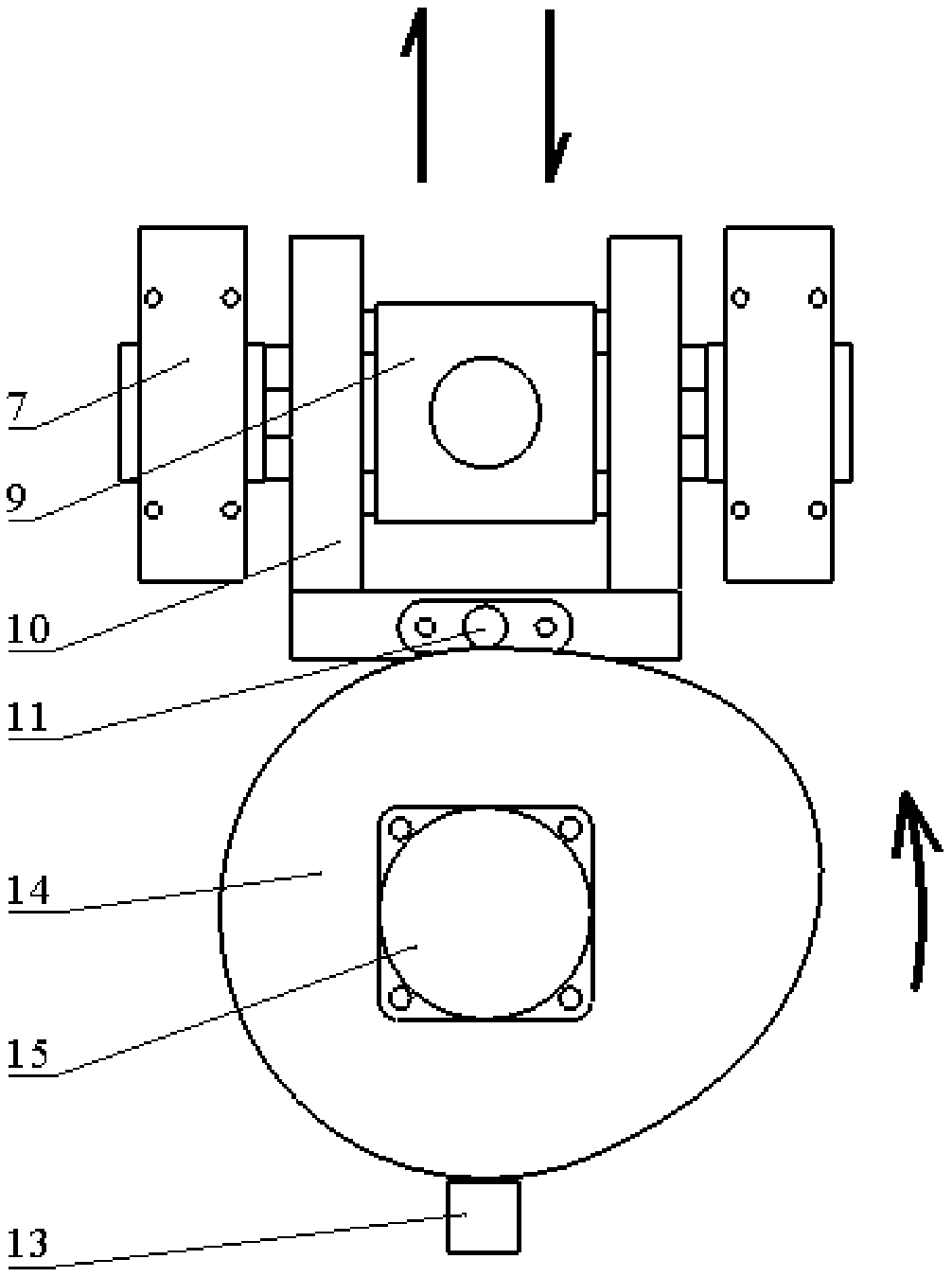

[0017] The on-line detection device for wood-based panel surface defects based on the principle of synchronization proposed by the present invention has a structure such as figure 1 As shown, it includes a conveyor belt 1, an encoder 4, a controller 5, a computer 6, a motor 15, a frame 13, a support frame 16, a workbench 10, a cam 14, a roller 11, a spring 12, a slider 8 and a camera 9;

[0018] The conveyor belt 1 is installed on the bottom of the frame 13, the artificial panel 2 to be tested is placed on the conveyor belt 1, the conveyor belt 1 is provided with a trigger switch 3, and the trigger switch 3 is connected to the controller 5 through a signal line; The encoder 4 is installed inside the conveyor belt 1 to measure the instantaneous speed of the belt and send the instantaneous speed of the belt to the controller 5;

[0019] Described motor 15 is connected with controller 5 by signal line, and motor 15 is installed on the bottom of frame 13 by support frame 16, as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com